Aluminum has excellent physical qualities that make it popular. The oxidized outer layer is unique in resisting corrosion. The aluminum material has a sturdy design that qualifies it to be fit for mechanical parts.

Aluminum properties make it favorable across many industries—for instance, aerospace, automotive, consumer electronics, and healthcare. Also, aluminum offers better machinability as compared to other metals.

The grades of aluminum allow it to get chipped easily. Furthermore, it is easier to penetrate it with cutting tools. Concerning that, aluminum offers three times machining ability than steel or iron.

Contents

Benefits of Aluminum CNC Machining

1. Machinability

As a rule thumb, it is easier to machine the aluminum metal. Such a property is advantageous to an aluminum manufacturing company. Or even better, it will be beneficial to the end-user who can manipulate it into different functions.

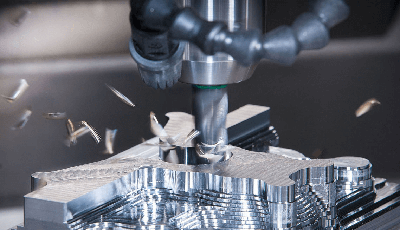

It is easy to shape the aluminum metal. Furthermore, one can chip it effortlessly. The user can involve a CNC tool to accurately and quickly cut it. For that matter, you will require a short timeframe to do your job.

Good machinability will lead to fewer deformations. The cutting tools will effectively go through the workpiece while retaining the shape. The machine will encounter tighter tolerance leading to higher accuracy.

2. Strength-to-Weight Ratio

Aluminum metal is suitable for mechanical parts. One remarkable property about aluminum is high strength. As is that it is not all, it is lightweight. In that regard, it is ideal for the aerospace and automotive industries.

In automotive parts, one can use aluminum on shafts. On the other hand, you can use it on the aircraft fittings. It is noteworthy that each grade of aluminum serves a specific role. For instance, the high strength aluminum grade, like 7075, is ideal for aircraft parts, while the 6061 grade is for other general uses.

3. Corrosion Resistance

Each grade of aluminum has a unique corrosion resistance level. Corrosion resistance talks about the ability to withstand chemical change and oxidization. Luckily, most of the popular categories like 6061 happen to be the most resistant.

Still, there are other categories of an aluminum ally that may offer less resistance to corrosion. Precisely, those aluminum grades alloyed with copper.

4. Electrical Conductivity

The electrical conductivity of the aluminum metal makes them ideal for electrical use. Aluminum metal has a reasonable conductivity property. Specifically, its conductivity is 27.7 siemens per meter. Such happens at room temperature.

It is noteworthy that copper material has a superior conductivity than aluminum. The aluminum alloys also prove to have less conductivity. They may also be more conductive than stainless steel.

5. Recyclability

Aluminum metal has high recyclability. You can apply it when running those enterprises that you would want to have a less environmental impact. Alternatively, you may wish to lower material wastage and avoid unnecessary costs.

Recycled materials play a critical role in CNC machining. It is because the process of cutting metals leaves various chips and a massive junk of waste materials. As a result, one can recollect them for further use.

6. Anodization Potential

Well, aluminum metal has aesthetic considerations, which makes it ideal for the electronics industry. Aluminum is also receptive to some substances like paints and tints. For that matter, you can treat it with anodization.

Painting or tinting the surface is a finishing procedure whereby it will thicken the protective outer layer. So what is anodization? Well, the answer is simple. It is the passing of the electric current within the part, usually in an electrolytic acid bath. It makes the aluminum piece to have high resistance to corrosion and physical impact.

Also, as you perform the anodization process, it will improve its bearing surface. For example, one can easily add color to the machined metal part. The dye will effectively stick to the surface to enhance the general outlook.

Alternatives of Aluminum in CNC Machine

Several metals may serve as alternatives to aluminum due to their various properties. They include:

a) Steel and Stainless Steel

Iron is also a popular metal in CNC machining. It’s high-strength makes it suitable for high-stress applications. You can also use it for situations that need strong welds. Still, the metal is resistant to high temperatures.

The stainless steel can offer a high corrosion resistance when treated. One downside of steel may be the heaviness and unusual hardness. Consequently, you may not use it for some applications.

b) Magnesium

Magnesium is a lightweight metal, although not as common as steel. Remarkably, it has a distinctive feature as the most machinable metal around. As you use it, it facilitates a fast and efficient machining process.

It is critical to note that magnesium chips are ordinarily highly flammable. A machinist needs to be cautious while clearing debris.

c) Titanium

Titanium has a credible strength-to-weight ratio. Titanium has the same weight as aluminum, although it is twice strong. Furthermore, it offers high resistance to corrosion. As a result, the titanium metal happens to be expensive.

You can use the titanium metal on aircraft parts, and other medical components. You can use titanium as an alternative to aluminum due to its excellent properties. However, you must be conscious of the budget involved.

d) Copper

Copper has almost the same features as aluminum. The only difference is that it has superior qualities to conduct electricity. Also, it is hard to machine pure copper. Alternatively, you can create a copper alloy that can offer you the same machinability in the class of aluminum.

In Conclusion

As a machinist, you will dream of using machine pieces that will facilitate your work effortlessly. In that regard, you should know the properties of the metals used. A proper metal should be easy to work on it.

Aluminum metal is one of the best metals around. You can know it by its lightweight design. Moreover, it has better machinable properties. One can use it for several industrial parts. Furthermore, it conducts electricity.

In case aluminum is absent, you can make use of other metals like titanium and copper to perform a similar task.

Rocheindustry specializes in high quality rapid prototyping, rapid low-volume manufacturing and high-volume production. The services of rapid prototype we providing are professional Engineering, CNC Machining including CNC Milling and Turning, Sheet Metal Fabrication or Sheet Metal Prototyping, Die casting, metal stamping, Vacuum Casting, 3D printing, SLA, Plastic and Aluminum Extrusion Prototyping, Rapid Tooling, Rapid Injection Moulding, Surface Treatment finish services and other rapid prototyping China services please contact us now.

Related source links:

White Paper: The Ultimate Guide To CNC Machining

White Paper: The Ultimate Guide To CNC Router

Handbook: The Ultimate Guide to CNC Rapid Prototyping

Handbook: The Ultimate Guide to CNC Lathe Machine

Handbook: The Ultimate Guide to CNC Manufacturing