CNC machining can be a simple topic and at the same time be a hard nut to crack. You should equip yourself with adequate knowledge about this technology if you are planning to get a CNC machining service.

Before you contact a CNC machine shop near you, there are some vital aspects of the technology that you should. This article is precisely curated to ensure that you make the right choices with everything that entails a CNC machine shop.

Contents

What is CNC Machine Shop?

Starting with the basics, CNC stands for Computer Numerical Control. This is a type of machine that is automated to operate with high levels of accuracy and Swedish precision. It is also capable of attaining high levels of complexity using the cheapest means available.

All these take place through the subtractive methods of manufacturing products.

In short, a CNC machine provides the a cost-effective option of producing products within a short time frame.

So, what is a CNC machine shop?

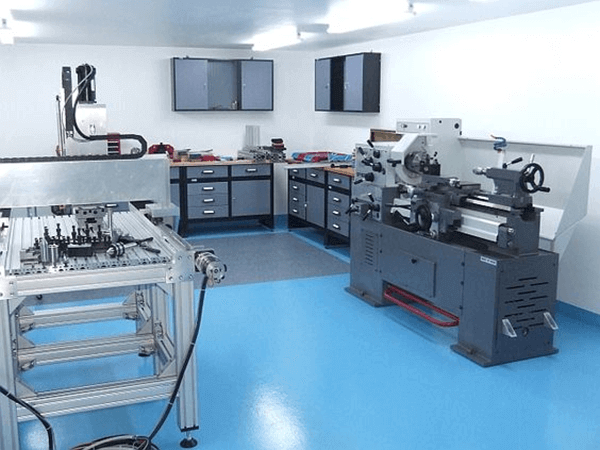

A CNC machine shop is a place or a building where CNC machining or subtractive manufacturing takes place.

It is not a store or a building where items are stored for buying. Instead, a CNC machine shop houses different machinery that is used for producing both simple and complex items using the subtractive manufacturing process.

The machine shop can be a large standalone shop or it can be a small section of a large factory building.

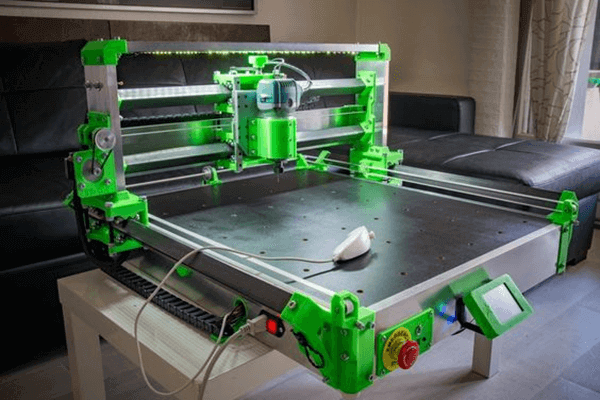

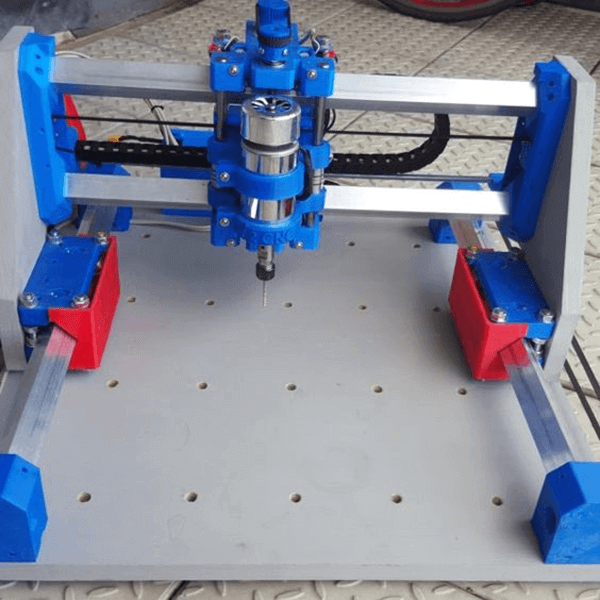

What kind of machines are in a CNC machine shop?

The machines that are in this type of shop are majorly used for the subtractive manufacturing process.

These machines mainly perform different tasks such as cutting, drilling, and shaping materials until you end up with a final desired product.

Also, 3D printers are some of the most conspicuous machines that you will find in a CNC machine shop. This is even though subtractive manufacturing is the main point of address by these shops.

Who are the owners of the CNC machine shops?

These shops are owned by different entities. Manufacturers of specific products can own the shop or it can be owned by third-party manufacturers who offer a wide range of CNC machining services online for different products.

With the second group, all that you need is to contact the shop owners online and tell them the product that you want to machine.

What you Will Find in a CNC Machine Shop

It is your first time to hear about a CNC machine and you don’t know what to expect from it. What are some of the equipment that you should find in the shop?

A typical CNC machine shop houses the following types of equipment or machines:

-Machining center

Also known as an automated milling machine, this is simply a fully computerized mill. This is to imply that every action of the milling equipment is controlled by a programmed computer. A machining center is capable of performing multiple functions at the same time.

-Milling machine

As the name describes, this is a machine that does the work of milling different materials. It has cutters that extrude material from a given workpiece. The milling machine is designed to come out with different types of cuts on a material.

-Lathe

The main function of a lathe in a CNC machine shop is to rotate a workpiece allowing other machines to work on it. For instance, it can rotate a workpiece while the cutting or sanding machines trim different parts of the workpiece. It is also known as a CNC turning center as it allows the workpiece to turn and expose its different sections.

-Measuring machine/Coordinating machine

From the definition, measuring is one major aspect of the whole machining process. The product must have precise measurements. A measuring or coordinating machine is designed to measure the geometry of the parts. This ensures that the final products meet the minimum specifications that you want.

-Surface finishing machine

An array of finishing is used on different products. Common tasks for the finishing machines include polishing, sandblasting buffing, and even coloring. A CNC machine shop should have tools for performing each of these finishing tasks.

-EDM machine

Electrical Discharge Machining utilizes electrical sparks to cut into and penetrate a workpiece. It bios one of the machines that make it possible for the CNC machine shops to work on complex products.

-Drill Press

A drill press is an alternative version of a hand-held drill. The motion of this drill is controlled by a lever and is capable of drilling into hard materials. A drill press is also more stable than a typical hand-held drill.

-Bandsaw

A Bandsaw of a CNC machining is mainly used for making straight cuts into a material. It also removes segments of the material before they are subjected to further cutting.

From this list, you can tell that many operations are executed in a CNC machine shop with the help of the CNC machines.

In addition to the machines, the shop can also house some raw materials which are used for making parts and final products. It all depends on the capacity of the manufacturer as some prefer to store the materials in different stores.

Difference Between CNC Machine Shops vs. Traditional Machine Shops

Computer Numerical Control (CNC) technology became popular just recently. In the past, and even now, we still have machine shops that are not fully automated. This means that some functions in these shops are still executed manually.

With CNC machine shops, all the movements of the equipment are computer-controlled. You can easily define the glaring differences based on the two modes of operations.

One of the differences in the complexity of tasks to be done. CNC machine shops are capable of performing more complex tasks and projects than traditional machine shops. This is because computers are somehow unlimited by the scope of work.

So, if the products or parts that you want are somehow complex or sophisticated, a CNC machining shop will be your best bet.

Another aspect of comparison is the accuracy level. Computer-controlled equipment operates with high levels of precision. This allows them to produce parts that have minimal errors. On the other hand, you are likely to record some errors with the manually-operated machines.

Time is also a factor when comparing CNC machine shops vs. traditional machine shops. Computer-operated machines are capable of completing large scopes of projects within a short time. This is contrary to the manual machines in the traditional shops where small projects are likely to drag for long.

It is easy to get customized products from CNC machining shops as compared to the traditional machining shops. All you need is to give them the requirement specifications of the products that you want. They will customize them according to your specifications.

The difference between a CNC machine shop vs a traditional machine shop is visible in terms of wastage. You are likely to experience a significant wastage from the manual method. The high levels of accuracy help to minimize wastage from the CNC machine shops.

What about the cost? Which one is cheaper between a CNC machine shop vs. a traditional machine shop? The use of technology helps to reduce the cost of production. Because of this, a CNC machine is relatively cheaper than a traditional machine shop.

Despite the differences, most machine shops strive to strike a balance between the use of traditional machines and the deployment of modern technology. For example, most of CNC machinists are fully knowledgeable about the operations of traditional machining. They deploy manual methods to work on simple projects that can be delivered within a short duration.

Tasks Performed by a CNC Shop Operator

CNC shops are run by operators who perform multiple functions. Some of the core responsibilities of the shop operators include:

-Ensuring that the CNC machine shop is fully equipped for handling different types of projects.

-Communicating with the clients and gathering their requirements for the products that they want. They also verify and load the instructions for each project.

-Communicating with other CNC shop operators to streamline the activities in the shop

-Monitoring the CNC machining process for each part and product

-Loading and loading both the finished and unfinished parts.

-Handing over finished projects to the customers

Quality control in CNC machine shop

In addition to all the other menial tasks, CNC machine operators are responsible for quality control. This task majorly focuses on ensuring that the quality of the parts and products meets the highest market standards.

Quality control starts with the verification of the materials to be used in the CNC machining. It has to be of high quality as it will affect the standard of the final product.

The aspect of quality control extends to the processing of manufacturing procedures. They have to be error-free and meet the highest standards of production.

In most CNC machine shops, there are special departments that deal with quality control. They use special tools and techniques to ensure that this aspect of production is fully satisfied.

Tips for Choosing CNC Machine Shop

Now that you know what a CNC machine shop is and the responsibilities of such a shop, the next step is choosing the best CNC machine shop for your project.

As simple as it sounds, choosing such a shop may turn out to be a complex task than what you think of. You need to be extra cautious otherwise, you may end up choosing a shop that will deliver underwhelming results.

Here are some tips for choosing the best CNC machine shop:

Inquire about the capacity of the CNC machine shop

It is important to know the capabilities and limitations of any given CNC machine shop. What can it do and what can it not do? This information will help you know the expectations of the shop that you are about to choose from.

Before you hand over your project to a CNC shop, inquire about the tools or equipment that they have. It is also prudent to find out the CNC machining methods that they use and the skills of operators in the shop.

Choose a shop only after you are satisfied with its capacity and capabilities.

Cost-efficient

The cost of CNC machining will always remain to be a thorn in the flesh. Even as you focus on the other factors, it will be hard to ignore the cost that is involved in producing different parts.

Find out the prices of CNC machine online from different shops.

Usually, it will be hard to resist the allure of choosing the cheapest CNC machine shop in China. It not advisable to go for this option simply because cheap may end up being the most expensive option.

Instead, look at what the shop does and compare it with the price. Choose a CNC shop that charges reasonable rates for the production job.

Thanks to technology, you can now request quotations from different CNC machine shops online.

CNC machine shop reviews

Just like when choosing other shops or manufacturers, you should also find out the previous customers or clients that have been served by the shop. From this information, you will be in a perfect position to predict what you should expect from the CNC machine shop.

It will be perfect if some of the clients are in the same production line as yours. This way, you will be sure of the shop’s capabilities.

Are you planning to get CNC machine services online? Check out the reviews and testimonials of any given shop. They will give you valuable insights on what to expect from the shop. Many positive reviews is a sign that the shop is capable of meeting your needs. We cannot say the same about negative reviews.

Privacy and confidential

CNC machining is a critical aspect of production. As a business, you won’t want any information about your product to be leaked to the public domain. So, you should choose a manufacturer that will assure you of privacy and confidentiality.

Conclusion

I hope that this information will be of great help when it comes to choosing a CNC machine shop in China. Do not let your project drag on due to the unavailability of the production partner. Choose the right shop and everything will flow smoothly according to your expectations.

Rocheindustry specializes in high quality rapid prototyping, rapid low-volume manufacturing and high-volume production. The services of rapid prototype we providing are professional Engineering, CNC Machining including CNC Milling and Turning, Sheet Metal Fabrication or Sheet Metal Prototyping, Die casting, metal stamping, Vacuum Casting, 3D printing, SLA, Plastic and Aluminum Extrusion Prototyping, Rapid Tooling, Rapid Injection Moulding, Surface Treatment finish services and other rapid prototyping China services please contact us now.