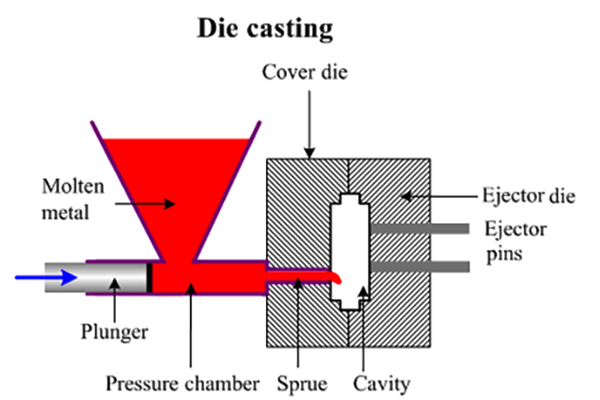

Die casting is a metal casting process that is characterized by forcing molten metal under high pressure into a mould cavity. The mould cavity is created using two hardened tool steel dies which have been machined into shape and work similarly to an injection mould during the process. Most die castings are made from non-ferrous metals, specifically zinc, copper, aluminium, magnesium, lead, pewter, and tin-based alloys. Depending on the type of metal being cast, a hot- or cold-chamber machine is used.

Are you looking for die casting companies in Malaysia? We have compiled the best 10 die casting companies list for you to pick as below:

Contents

Sena Diecasting Industries

Creating Values Through Consistent, Cost Effective & Timely Delivery to Our Global Customers Since 1996

Sena Diecasting Industries (SDI) has more than 2 decades of experience in manufacturing top quality products to famous brand names in the world. Our returning customers are the results of stringent quality control system and 5S Management put in place to ensure 100% customer’s satisfaction. We pride ourselves to be the one stop solution diecast manufacturer in Malaysia with in house Chrome Plating and Powder Coating line.

Our aluminium high pressure die cast products are used in Automotive Industry, Lighting Industry, Electrical and Electronic Industry, Medical Equipment, Oil and Gas Equipment and many others. Over 80% of our customers are located around the world mainly to United States of America (USA), South America, United Kingdom (UK), Netherlands, Germany, China, Japan, Thailand, Singapore and India.

Our company philosophy is to embrace new technology in our manufacturing processes. Equipment upgrades coupled with introduction of automation and robotics are our main focus to ensure high quality, cost effective and on time delivery.

Address: Lot 131, Jalan Permata 2, Kawasan Perindustrian Arab Malaysian, 71800 Nilai, Negeri Sembilan, Malaysia

ISTX Precision SDN BHD

STX Precision Group is involved mainly in engineering supporting services (ESS). We are a reliable manufacturer of precision metal parts and components using high-pressure die-casting of aluminium and zinc alloys.

We supply to multi-national companies (MNC) present in the South-East Asia region and also export to their worldwide operations. Our products and services cover wide spectrum of industries including consumer electrical/electronics; industrial products; telecommunication; automotive; and storage testing devices.

Address: Lot 153 (No. 17A), Jalan Angkasa Mas 6, Kawasan Perindustrian Tebrau II, 81100 Johor Bahru, Malaysia

Malaysian Die-Casting Industries SDN BHD(MDI)

Since 1980, MDI has been involved in supplying customers with finished metal products. In that time we grown to offer quality precision-machined die-casting products to clients in a range of industries and geographies. We’re currently located on 2 factories over a 7 acre lot with a total factory space of approximately 200,000 sq ft (20,000sq mt) in Shah Alam, near Kuala Lumpur in Malaysia, employing a workforce of 320 covering business development, & administration, engineering, research & development, quality assurance, manufacturing, and logistics.

Our team of senior engineers and management have a combined experience in the casting industry of over 100 years. We are constantly looking forward to improve ourselves through R&D and technology exchanges with US, Switzerland, Japan and Australia. Looking forward, we leverage our engineering experience with the latest technology to provide our customers with a complete die-casting solution from design reviews (considering customer requirements, cost implications, and manufacturability) to delivery of quality , cost-efficient products.

Address: Lot 58, Jalan Hulu Tinggi 26/6, HICOM Industrial Sector A, 40000 Shah Alam, Selangor Darul Ehsan, Malaysia

HICOM Diecastings Sdn Bhd

A leader in precision aluminium die casting, HICOM Diecastings Sdn Bhd is one of Malaysia’s most well-known industrial companies and a leading supplier of world-class aluminium die cast products and services to some of the biggest names in the local and international automotive, motorcycle and related industries.

Incorporated in 1985 and fully owned by DRB HICOM Berhad, HICOM Diecastings provides its clients with a cutting-edge combination of technology, technical know-how and a highly-skilled workforce that have made it the leading die caster in the region. The company focuses on its core competencies to continuously evolve and mould its vision to spearhead the industry’s future.

HICOM Diecastings utilises only the most advanced technology available at every stage of production to ensure components of the highest quality. Innovation, the ability to facilitate change and meeting a growing number of international manufacturing and management practice requirements has led to the company being awarded ISO/TS16949, ISO 9001, ISO 14001 and OHSAS 18001 certifications.

HICOM Die casting’s commitment to quality and continual improvement processes ensure that our complete precision die cast solutions exceed customer expectations in terms of cost, quality, development and delivery. Today, the company’s quest for innovation has led us to becoming the world’s most technically advanced manufacturer of quality die cast components.

Address: Lot 16, Jalan Sementa 27/91, Section 27, 40000 Shah Alam, Selangor D.E. MALAYSIA

Castmax (M)Sdn Bhd

Castmax (M)Sdn. Bhd. (Company) is a manufacturer of aluminum alloy and zinc alloy die-cast products. The Company was incorporated in Malaysia under the Company Act 1965 as Private Limited Companies.

The factory cover-area is about 23000 sq. which located in Sungai Buloh, Selangor, Malaysia which is 15 minutes drive away from Subang Terminal airport.

We are customer-oriented organization and working towards to be leader in the field of aluminum and zinc alloy die-casting, mould design and development. Our services also includes value added processes such as polishing, precision tapping, riveting,CNC machining and assembly.

We at Castmax committed to comply with below stated polices:-

1- Consistent Quality

2- On time Delivery

3- Competitive Cost

4- Customer Satisfaction

We practice continuous improvement activities through our in house processes and strive to advance our expertise in die casting, secondary and machining processes to a sustainable growth in this industry.

We look forward to work with you and committed in providing quality products at competitive price to your door step.

Address: AL 22C,22D & 22E, Lot 840, Kampung Baru Sungai Buloh, 47000, Sungai Buloh, Selangor, Malaysia

Newbillion Precision Metal Sdn Bhd

Newbillion Precision Metal is an ISO 9001 and IATF 16949 certified one-stop engineering solutions provider in Penang, Malaysia. We are specialised in high-pressure aluminium & zinc die casting, precision CNC machining, and sub-assemblies of precision components.

Our flexible production systems coupled with 30 years of expertise enable us to offer solutions perfectly suited for low volume manufacturing, mass production and anything in between.

With a strong track record supporting the world’s leading companies, we are capable of providing engineering solutions in the Medical, Automotive, Electrical & Electronics, and Industrial market sectors.

NBP’s fully equipped metrological lab and commitment to quality ensures that your precision components are produced with the highest standards of quality.

Address: 49, Jalan Usahajaya, Kawasan Perindustrian Usahajaya, Permatang Tinggi, 14000 Bukit Mertajam, Penang, Malaysia

LVIO Precision Sdn Bhd

LVIO Precision Sdn Bhd (“LVIO”) is an Independent Service Provider (ISP) in Engineering Support Services (ESS). LVIO was incorporated as a wholly owned subsidiary of STX Corporation Sdn Bhd in 2009 to service its clients in the northern (Penang) region of Malaysia. In 2016, the STX Corporation Group went through a corporate restructuring whereby some of the senior management did a management buyout and took over the ownership and management of LVIO.

LVIO started small in 2009 but today, LVIO is a qualified and approved vendor providing a full spectrum of services covering:

1. tooling design and fabrication (moulds, tools & dies);

2. non-ferrous metal die-casting;

3. secondary processes;

4. precision machining;

5. coating and surface finishing;

6. assembly of mechanical components; and

7. supply chain management.

LVIO has grown from strength to strength – thanks to the confidence that our clients have in us. Today, LVIO is serving many industries such as industrial and consumer goods; technology; automotive; telecommunication; etc. All these have been made possible by our team of dedicated and skilled employees and also through our partnership with a network of specialist partners who complement our services, thus allowing us to deliver unparalleled services to our clients. Our strategic partnerships have allowed us to expand our scope of products and geographical locations without limitations.

Address: No. 1867 Lot 2792 Jalan Industri 2 Kawasan Perindustrian Bukit Panchor, 14300 Nibong Tebal, Penang, Malaysia

Eko Industries

EKO’s progressive growth is driven not only by our desire to bring high quality die casting and sheet metal parts to our customers, we do also provide MECHANICAL SUB ASSEMBLY PROCESS in our control room yet exceed customer expectations and prove that we are the best, while at the same time raising Malaysia’s profile internationally.

The company endeavors to conduct its business with full vigor and enthusiasm by providing opportunities for growth for all its stakeholders through the continuous improvement of its employee’s skills and knowledge as well as the upgrading of its technological and process capabilities within the highly competitive Aluminum precision Die Casting industry. This, together with the right ideology, business model and strategic mind-set, enables the company to ensure continuous high value, quality parts and services for its current esteemed customers as well as to match or exceed future stringent demand standards. With strategic manufacturing objectives in place, EKO poses the ability to move forward by placing a strong emphasis in providing value added services to its customers.

Our primary business activities are currently well supported by EKO Metal Industries Sdn Bhd (EMI), which specializes in Al/Zinc precision die-casting products while EKO Industrial Parts Sdn Bhd (EIP) offers unsurpassed expertise in sheet metal chassis, covers, box-builds as well as Aluminum extrusion, metal stamping panels and machining parts that consistently exceed rigorous and discerning MNCs and domestic export-oriented customer’s quality standards.

Address: Lot 667 & 668, Juru 14000 Bukit Mertajam, Pulau Pinang Malaysia

CASTCO Sdn Bhd

Castco produced high pressure die casting parts in Aluminium. Castco is founded in 2010 that has grown significantly over years. With expertise and experience bring forth our commitment to provide sustainable solutions to manufacturing with vision as extended enterprise and enhance quality of life for all.

Castco is ISO9001 : 2015 certified. Consistently meet or exceed customer’s expectations for production quality and performance. With capability to develop product with customer, understand production requirement for Quality Control Management, we offer solution and support improvement.

Address: 7962, Jalan Segenting, Telok Panglima Garang, 42500, Selangor, Malaysia

Nakazawa Die Casting (M) Sdn Bhd

Nakazawa Die Casting (M) Sdn Bhd is one of the leading companies in the zinc die casting industry. The Company was incorporated in 1988 with a paid-up capital of RM 3.7 million. Since then, our early beginning from a shoplot has expanded into 2 factories with a total built-up area of 51,132 sq. ft. and our 5 employees have since multiplied to the present workforce of 300 trained personnel.

The company is well equipped with all the facilities that are needed to manufacture our products. Our modern technology is constantly upgraded in order to meet the requirements of today’s challenging demands. A special feature of our manufacturing is our in-house Designing and Fabrication of zinc die casting molds. This enables us to meet customers’ stringent requirements and stay competitive in the industry.

Address: LOT 46910 Block D & LOT 46902 Block L, Taman Perindustrian Selayang, 68100 Batu Caves, Selangor Darul Ehsan, MALAYSIA

Conclusion

How to choose right die casting services company is very important, Without looking further, we’re also die casting services company in China. Rocheindustry aim to give purposeful reviews and information that is bound to save your time. In case of any questions, inquiries, or even comments, reach out to us.

Remember, a happy client is a happy company.

If you’re looking for die casting services with competitive price in China please contact us as below button.

Related source: White Paper: The Complete Guide To Die Casting