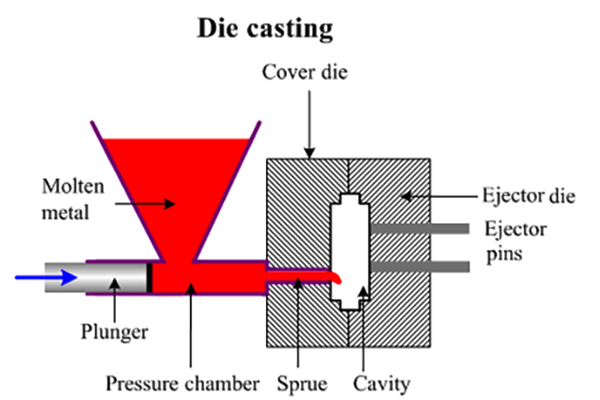

Die casting is a metal casting process that is characterized by forcing molten metal under high pressure into a mould cavity. The mould cavity is created using two hardened tool steel dies which have been machined into shape and work similarly to an injection mould during the process. Most die castings are made from non-ferrous metals, specifically zinc, copper, aluminium, magnesium, lead, pewter, and tin-based alloys. Depending on the type of metal being cast, a hot- or cold-chamber machine is used.

Are you looking for die casting companies in the USA? We have compiled the best 10 die casting companies list for you to pick as below:

Contents

Kinetic Die Casting Company

Kinetic Die Casting Company (KDC) was established in 1994 near Los Angeles, California at the current location in North Hollywood, California. Kinetic Die Casting Company is an American Jobshop Aluminum Die Casting Company. A jobshop aluminum die casting company produces aluminum die casting parts for OEM’s (Original Equipment Manufacturers) for their products. A Die Casting Company uses a process in which molten aluminum is injected with a die casting machine under force using considerable pressure into a steel die casting mold or die casting die to produce aluminum die casting parts.

Address: 6918 Beck Ave, North Hollywood, CA 91605, United States

Empire Die Casting Company

Empire is an Aluminum & Zinc Die Cast Company that was founded in 1948. A family owned business where three separate plants merged together. Empire originally was an Aluminum Plant in Maple Heights, Ohio. Industrial Castings was the Zinc Plant in Cleveland, Ohio & Kay Tool was the machining portion of it. In 2000, the family decided to bring them all together here at the Macedonia, Ohio location. Our diverse customer base that we produce for includes but is not limited to industries in medical, locomotive, oil & automotive. We harbor the following tonnages between the Aluminum and Zinc die cast machines within our over 200,000 square foot manufacturing facility.

Address: 635 Highland Rd, Macedonia, OH 44056, United States

Ryobi Die Casting (USA) Inc

Ryobi Die Casting is leading the industry in high-pressure aluminum die castings. As a tier-one supplier to the automotive industry, we are dedicated to providing our customers with only the highest quality castings on time.

Our products include transmission cases, housings, engine parts, and most recently, structural parts. Our part are used in a number of Ford, GM, and Honda vehicles.

Address: 525 Industrial Park Dr, Shelbyville, IN 46176, United States

Aallied Die Casting Company of Illinois

RCM Industries, Inc. is located Franklin Park, IL and is a die casting parts manufacturer as the parent company to four die casting companies. All of which are IATF 16949:2016 certified manufacturing facilities.

The combined purchasing power and shared expertise of our multiple manufacturing facilities creates knowledge sharing, economies of scale, and flexible production scheduling synergies found in large die casting organizations, along with the personalized service of a captive operation.

RCM’s four die casting manufacturing plants are strategically located to meet the casting, machining, and finishing needs of a wide variety of markets.

Address: 3021 Cullerton St, Franklin Park, IL 60131, United States

Carteret Die-Casting Corporation

Our engineering staff has accumulated over a century of practical die casting experience and they are expert in the areas of tool design and construction. We are an engineering resource for our customers when value analysis projects or new parts are being designed. We provide practical solutions to die casting problems and can meet your zinc die casting requirements.

At Carteret, customer service is our priority. Experience the Carteret advantage and let our capable sales and service staff assist you from the quote process through production. We will make every effort to satisfy your needs.

Today’s volatile business climate demands tighter inventory management while ensuring adequate stock to support unplanned business opportunities. Carteret’s computerized production management system tracks customer orders from inception to completion and can provide real time order status information upon request. Our recent facility expansion provides the necessary space to support flexible shipping plans such as JIT, CONBON, ship-to-stock and blanket contracts with multiple deliveries.

At Carteret, we care about quality! Carteret’s Quality Management System has been certified to the ISO 9001. Our highly skilled quality assurance team utilizes state of the art measuring equipment, as well as advanced quality planning and statistical quality assurance techniques to ensure our customers products are produced to specification from initial sampling through production runs.

Address: 74 Veronica Ave, Somerset, NJ 08873, United States

Apex Aluminum Die Casting Company

Apex Aluminum Die Casting Co. Inc. was founded in 1980 and has remained a family owned and operated business. We are proud to serve a wide variety of industries across the United States. Our 100,000 square foot facility is conveniently located in the heart of the Midwest, just 30 miles North of Dayton, Ohio off I-75. Please contact us today to arrange a plant tour and see how we can meet your casting, tooling, machining and finishing needs.

At Apex, we can offer you world class, American made, service and support for your low to mid-range volume die casting needs. Our mix of 14 custom built manual and automated die cast machines allows us to accommodate a wide range of high pressure die casting parameters including multiple hydraulic and mechanical slide pulls and many casting insert load demands. Each of our machines is paired with an individual furnace providing us ultimate flexibility. We can cast parts from 1oz to 18 lbs in any aluminum or zinc alloy and can meet your short run order quantity needs of 1 piece up to 100,000 a year.

Address: 8877 Sherry Dr, Piqua, OH 45356, United States

A & B Die Casting

The future is redefined by the past. A great company begins with a simple vision.

In 1924, Ben Dathe immigrated to the United States from Dresden, Germany in order to pursue his dream of owning his own tool and die company. He had started his tool and die apprenticeship in the old country at the age of 14.

Twenty-one years later, Ben proudly opened the doors of Benda Tool in Berkeley, California. The company name was taken from the first five letters of his own name. From the outset, Benda Tool established a reputation for personal service and high quality manufacturing.

Early on, Ben recognized the potential of die casting. Encouraged by his best customer, Ben created a new die casting company called A&B Die Casting. When Ben’s son, Bob, joined the business sporting a degree in mechanical engineering, Benda Tool and A&B Die Casting, were united in a new 5000 sq. ft. plant.

That simple move ignited the company’s future.

Growing Ten-fold.

In 1999 after 40 years in Berkley, the company moved into a brand new state-of-the-art facility in Hercules, California. Now, under one roof A&B could provide the full and complete line of services. Since the move A&B Die Casting grew 10-fold by making advanced die casting aluminum components for scientific instruments, medical hardware, architectural lighting, microwave technologies, telecommunications, computers and more.

Today A&B Die Casting offers its customer a diverse range of services including engineering, design, custom die casting, machining, finishing, and assembly – in short, a complete range of precision die casting services for Dock to Stock and Just in Time service.

As a boy, Ben Dathe was always curious, searching for ways to refine his vision and bring innovation to need. He instilled in his company the desire to optimize whatever process was necessary to get the job done. Optimize service. Optimize value.

A&B Die Casting Company Founding Traditions.

His driving passion for excellence coupled with his family’s rich tradition and deep appreciation for engineering, design, and modern technology have allowed the business to redefine itself in new technologies, but always forged in the founding traditions of the company. This approach – has earned A&B the respect and confidence of many customers over the past 60 years.

The future of the company now rests on the shoulders of Ben’s Grandson, Steve Dathe. With a degree in manufacturing engineering and a passion for technology, Steve is committed to employing state-of- the-art equipment and information integration systems that ensure part consistency, quality, precision and timely delivery, echoing a great family tradition for excellence.

Address: 900 Alfred Nobel Dr, Hercules, CA 94547, United States

American Precision Die Casting

American Precision Die Casting was formed in June of 2005. As a privately-owned manufacturer of die cast parts made from aluminum alloy 380, American Precision Die Casting (APDC) is located in Cuba, Missouri, about 70 miles southwest of St. Louis just off Interstate 44. The manufacturing facility is 26,600 square feet and situated on five acres of land with plenty of room for future expansions. With a dedicated workforce of 65 associates, APDC runs three shifts, 24 hours each day Monday through Friday (and Saturdays when needed).

Address: 100 American Way, Cuba, MO 65453, United States

Aluminum Die Casting Co Inc

Founded in 1950, Aluminum Die Casting Co., Inc. is a third generation family owned and operated manufacturing business. With Steve Bennett as President, Michael Bennett as Vice President/General Manager the two are strongly committed to continuous improvement,cost reduction, on-time delivery and 100% customer satisfaction. After 50 plus years we now occupy a 35,000 sq. foot facility in Mira Loma, California. We strategically selected this location to be convenient for all of our: customers, vendors, employees and very close to Ontario International Airport.

ADC specializes in short or medium run requirements (50 to 100,000) and we are flexible enough to handle your expedited requirements for tooling and production complete to your solid model and specifications including: Billet CNC Machining, Mechanical Assembly, Plating, Powder-coating and Painting.

With our ISO 9001 registration and AS9100 certification, ADC meets your exact specifications using state of the art equipment, a strong management team, and a highly skilled, stable workforce with an average tenure of 14 years at ADC.

Aluminum Die Casting Company was started in 1950 by Mr. Gene Woods and Mr. Larry Strom. Their skill set of sales and tooling enabled the partners to grow the business rapidly specializing in parts for the Aircraft Industry.

In 1978 the company was acquired by the Bennett Family. Today we have two generations active in the business. The company moved from Los Angeles to our present location in Riverside in 1988. With the addition to our new, digital high speed equipment, and our team of skilled craftsmen we have the capacity to service your needs into the 21st century and beyond.

Our Castings and Billet products proudly serve the US Military. Take a few minutes and browse through our website to learn more about our unique.

Address: 10775 San Sevaine Way, Mira Loma, CA 91752, United States

KenWalt Die Casting Company

KenWalt Die Casting Company is an ISO 9001 Certified ITAR Registered American Die Casting Company in the USA manufacturers of high quality aluminum die casting and zinc die casting. Aluminum casting and Zinc casting such as Automotive castings, aerospace castings, medical castings, industrial castings, computer castings, solar castings, telecommunications castings and many other industries for over 50 years.

KenWalt Die Casting Company https://kenwalt.net 1-800-KENWALT, 8719 Bradley Ave Sun Valley, California USA

The Pressure Die Casting Process is where molten aluminum and zinc metal alloys are injected under force into steel die cast dies or die cast molds in die casting machines to produce metal die cast parts.

KenWalt Die Casting Company is the Best Die Casting Company in the USA and is able to die cast and deliver finished aluminum and zinc die cast parts for customers throughout the world.

KenWalt Die Casting Company has an excellent reputation in the die casting industry for producing the highest quality and lowest price aluminum and zinc die cast parts using vacuum die casting, automation and expert die casting design techniques.

KenWalt Die Casting Company die casting design experts will help handle all your needs die casting aluminum zinc part design improvements, die casting prototypes, die casting molds, die casting engineering, die casting tolerances, machining, surface finishing and assembly.

Address: 8719 Bradley Ave, Sun Valley, CA 91352, United States

Conclusion

How to choose right die casting services company is very important, Without looking further, we’re also die casting services company in China. Rocheindustry aim to give purposeful reviews and information that is bound to save your time. In case of any questions, inquiries, or even comments, reach out to us.

Remember, a happy client is a happy company.

If you’re looking for die casting services with competitive price in China please contact us as below button.

Related source: White Paper: The Complete Guide To Die Casting