Times have changed technologically, and there has been an inevitable tremendous revolution in industries. Factories are jumping into this revolution to maintain a top position in their productivity. The demand for products is increasing, and therefore factories must increase their innovative skills to meet demand. This has transpired to the adoption of 3D Printing, a technology that has dramatically trended recently.

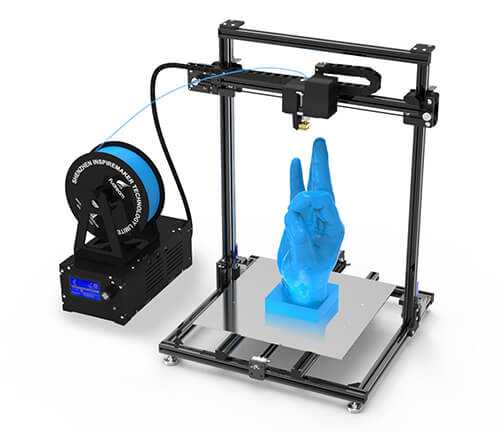

3D Printing is a modern process of using a three-dimensional digital model to make a physical object. It’s an innovative approach that involves manipulating objects in their digital format and creating new shapes. The application of 3D Printing will gradually shift factories from the traditional methods of manufacturing.

By enacting the 3D Printing in factories, a quicker production system will ensure the factories meet the market demand conveniently. Also, through this technology, factories will significantly reduce human labor in industries.

Contents

Application of 3D Printing

Since the knowledge of 3D Printing came up, factories are benefiting big time with the application of 3D Printing. Time and resources have been saved in the production process. Many industrial sectors have enjoyed 3D printing implementation. Here are examples of the industries that can be great beneficiaries.

1.Automotive

Automotive factories can immensely benefit from the application of 3D printing skills. This is because by incorporating improved materials in their production processes, they can get outstanding results. They will produce spares, engines, and replacement parts easily, hence meeting the market demand.

2.Jewellery factories

There has been a lot of tedious work involved in the traditional way of making jewelry. From fabrication, casting, engraving, and polishing, a lot of skills and time are required. Fortunately, this technology can change things in factories. The change will be enabled by the 3D design features, which not only bring out various spectacular designs of jewelry but also saves time and attracts a wider market. The 3D Printing will be a great relief to the factories.

3.Food Factories

With the drastic population growth that is worldwide, the need for more food has equally gone up.3D Printing will enable factories to prepare and present food easily. Not only will this technology help in food preparation, but also it will help in balancing nutrients in the food. Therefore, the future of 3D Printing in the food factories is clear.

Benefits of 3D Printing To Factories

Compared to the traditional process of manufacturing, there are vast benefits of 3D Printing. Here are some of the major benefits that factories will enjoy from the 3D printing implementation.

A) Saves tools and maintenance costs

Many factories use a lot of tools in their manufacturing processes. These tools often get spoilt or even tear and wear. This automatically translates to the need for their repair. Sometimes, the tools are not readily available in the market, which means that time will be wasted searching for these tools. Also, there is the cost of buying new tools and maintaining the new old ones. Contrarily, this story changes with the new technology. That’s because 3D printing tools are strong and reliable, and most importantly, they are easy to find.

B)Time and availability of products

Consumers are very sensitive when it comes to time taken in accessing products. No one wants to go round and round, searching for something. They also want value for their money, and therefore quality is of the essence. These demands cannot be met through the traditional way of manufacturing. This is why factories need to embrace the 3D Printing .3D Printing can help reduce the demand and supply gap within a short time. Also, with the 3D Printing CAD software, factories will develop new ideas, thus boosting their products’ quality.

C)Flexibility

This technology is broad and allows you to create anything within its ability. Unlike the old way, every stage of the process requires a new tool; the 3Dprinting slicer software manufactures consistently.3D Printing is diversified and can do any geometric work in a solid material. Additionally, it allows more than one material of different colors and mechanical features to be mixed. Many 3D printing designs allow the manufacturing of various products with different features.

D) Environmental friendly

3D printing technology doesn’t require so much outsourcing of products. This means less shipping of manufacturing materials, and that’s a plus to environmental safety. They don’t operate like energy-consuming factories that release a lot of pollution to the environment. This is because instead of reducing materials, the 3D Printing adds on materials, thus cutting on material wastage. The materials for 3D Printing can be recycled and are safe for the environment.

E) Easy Training

The 3D training is not an uphill task, and anybody interested can access it. There are various training programs that factories can adopt for the training of their manufacturing teams. The training will also not interrupt the factories’ work program, and this will go on as usual. Moreover, the 3D training program has extensional training that will train your staff on handling materials and what to do with products after processing.

F)Consistency

Consistency is a major factor if any factory will achieve its production goals. Most factories operating traditionally face a lot of inconsistency. This is because they end up with defective products and less quality. This is, however, not the case for the 3D Printing, which has consistent Printing. Printing is also well monitored to avoid defects. The consistency cuts down on wasted materials and enhances quality work, and boosts the consumers’ confidence.

Conclusion

With this knowledge, it is in order to say that the future of factories lies in 3D Printing. Many benefits come with the application of 3D Printing. In any industry, the demand for a product dictates the supply of the same. For this reason, factories need to invest in 3D printing technology and be able to satisfy their customers. Besides, meeting the demand levels, quality is of the essence if they will maintain their consumers. This factor will be enabled through the 3D printing organs that are well refined for quality results. With additive manufacturing, factories are guaranteed of a promising future and more income. Therefore,3D Printing should be every factory’s priority. Lastly, if by any chance you need any 3D service, contact rocheindustry 24 hours customer service desk