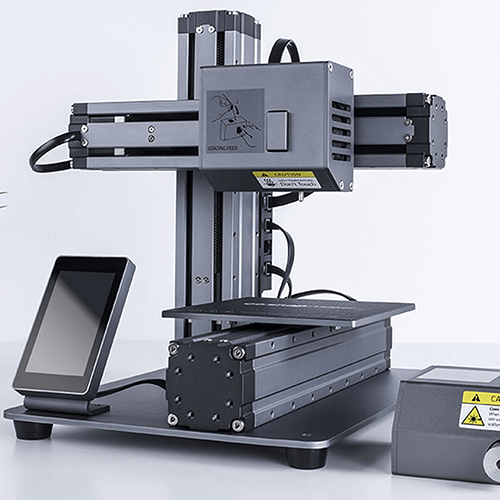

CNC (Computer Numerical Machines) are gaining popularity in the manufacturing world. You will advance your manufacturing process when you implement their principles.

So, what is CNC manufacturing? It is a process that will automate, control, or monitor various movements in the machines to get the end product. Some of the machines may be milling, laser, robot, and more.

You can still use an external PC to operate some of these machines. They combine with CAM (Computer Aided Machining), which creates a code for the CNC machine to follow. There is a great demand for CNC programmers due to the widespread application of the CNC machines.

You can adopt these machines whether you are working in big industries or a small workshop. One great advantage of using these machines is that they are cost-effective. Furthermore, they will allow a higher level of accuracy and extreme precision.

Contents

Services offered by CNC Machines

The CNC machining process comes with various techniques to produce your desired products. Some of the machining techniques include the following:

Drilling: The machine brings a rotating cutting tool which gets in contact with a workpiece to create a hole.

Boring: The process involves removing materials to form a particular inner cavity within your workpiece.

Turning: It is a process of rotating your workpiece for it to contact a cutting tool. The most common ones are lathe. Also, the process will enhance the ability to design cylindrical parts with tight tolerance.

Broaching: the technique involves the removal of materials, leaving a series of shallow cuts.

Milling: It brings a rotating cutting tool to get into contact with your stationary workpiece. The process is ideal information of the underlying geometry shapes.

Sawing: The CNC manufacturing technique involves a saw blade to cut a narrow slit in your workpiece.

Understanding CNC Manufacturing

CNC machining is a subtractive technology to get your end product. It involves selectively removing any excess materials in the workpiece. The production process will follow four stages, as discussed below.

Part Design

Every part that the CNC machine produces is a reflection of CAD software. During the design phase, the engineers will give it due attention to the workpiece to have the final product aspects.

They will ensure the design has the required parameters for the performance. Furthermore, it should have the operating conditions for that particular end part. Finally, the product should have an acceptable tolerance level.

Design Conversion

As you complete the initial design phase, you will have to convert the CAD model into a functional CNC program. In this case, you will use the Computer-Aided Machine software.

The software will be extracting the precise geometrical requirements from the original CAD model file. It will later translate them into a compatible programming language. They may be either G-code or M-code that will determine the mechanical operations of your machine.

CNC Machine Operation

As a CNC machine operator, you should set up the machine and later target the material in line with the specifications as per the CNC program design. Ensure that the machine has correctly installed drilling or cutting tools to match the appropriate bits.

Still, the operator should set up the workpiece. It may be in a stationary clamp, or you can attach it directly to the CNC machine.

Executing Programmed Operations

At this point, the CNC operator should execute the right mechanical processes. During the procedure, the CNC program will control the machine movements precisely. In the end, you will find the desired finished product.

Materials used on CNC Manufacturing

You need to cross-check the materials that you will be using for CNC manufacturing. You should gauge them over the following parameters:

- Chemical resistance

- Thermal resistance

- Ease of operation

- Hardness

- Tensile strength

- Weldability

- Machinability

- Price

How to select the material for CNC Manufacturing

The best way to know the right material is by consulting an expert. Your budget will play a critical role in the whole process. There are various material options in the market as follows:

1. Plastic

You can use CNC machines to produce different plastic products for multiple functions. One of the functions of plastic products is in the making of electrical insulation. You can consider plastic as a prototyping material when making the end part with injection molding.

Plastic materials come in various grades. The PTFE grade is suitable for electrical components as it has good heat and chemical resistance. The POM plastic is ideal in the making of mechanical parts due to its good machinability.

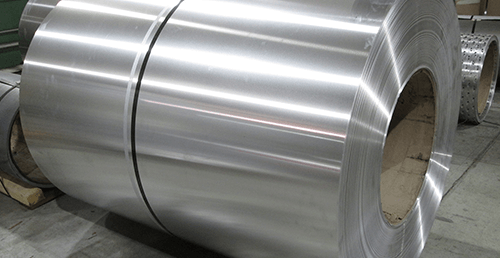

2. Aluminum

Aluminum materials come in various grades to enable CNC manufacturing. For instance, you can use aluminum grade 6061, which is suitable for manufacturing bicycle frames, motor vehicle parts, and sporting goods.

Another useful aluminum grade is 7075. It is helpful in the manufacturing of high-strength recreational equipment. The metal will undergo particular stress to make aircraft and automobile frames.

3. Brass

You can use the brass material to manufacture various items for use. The CNC machine will produce musical instruments, home décor, and plumb fitting. Brass has high polish; hence it is ideal in the making of cosmetic items.

4. Stainless Steel

There are multiple grades of stainless steel that you can use in CNC manufacturing. For example, you can use grade 303 to make various products like gears, shafts, and nuts.

Furthermore, there is grade 304, which is non-magnetic. You can use it when manufacturing consumer products like pipes, tanks, and kitchen accessories. Depending on your needs, you can choose the right grade for your work.

5. Titanium

It is the right materials for manufacturing various consumer products. Titanium has desirable properties like toughness, high strength, and lightweight. However, it is a poor conductor of electricity.

It is among the costly metals which manufacturers use for various applications like biomedical applications, aerospace, and military.

6. Wood

Wood is a common material for CNC manufacturing. You can use hardwood, softwood, or plywood in making various designs.

7. Foam

Foam is the lightweight material that you can involve in making various products. The foam comes in multiple types like rigid or carving foam.

Application of CNC Manufacturing

CNC manufacturing machines have various applications in life. You can apply CNC manufacturing in the following areas:

· Firearms

You can involve the CNC machines in the making of different types of firearms. They may include ammunition clips, barrels, pins, and various components of guns.

· Electronics

CNC machines will manufacture various electronic products like motherboards and computers. As if that is not over, they make other related products like phones, TVs, tablets, and more.

· Metal Removal Industries

Multiple manufacturing industries will require CNC machines in the manufacturing process. They use this technology in the removal of excess metals on certain metals to make the final product.

The process will see one get various shapes of metals specifically for multiple functions—these shapes like rectangular, rounded, threaded, or square.

Benefits of CNC Manufacturing

a) High production and Scalability

As you enter the correct parameters in the CNC machine, it will produce the end products in larger quantities. It also supports flexible Scalability.

b) Precision Components

The digital template will reduce human error and strive to achieve high accuracy. The produced items will manifest in the right dimensions that reflect the manufacturer’s intentions.

c) More Capability

The CNC machines will produce certain outputs that are difficult to replicate while using manual machines. It can still be challenging to create similar designs by any gifted engineer who will be using conventional machines. You can use the CNC machines to manufacture items in any shape, size, and the needed texture.

d) Less Labor

You will require less human resources in the execution of tasks. You may only require single skilled labor to run various CNC autonomous machines. On the contrary, one manual machine may need several people to make it fully functional.

e) Safety

It is safer to use CNC manufacturing machines since they will not expose you to shaper objects. The case is different in other convectional machines since the operator will come in contact with the metal parts while drilling or punching.

f) Design Retention

As you load the design in the CNC machine, you can save the specification to use it when needed. It will eliminate the need to keep various versions of the file on secondary devices like flash disks.

Disadvantages of CNC Manufacturing

The CNC machines are not cheaper options. You must plan well before you acquire the right machine that will serve your needs effectively.

Another downside of these machines is that they tend to make the manual option to be obsolete. As a result, the operators may lose their jobs.

Wrapping Up

Well, the use of the CNC manufacturing process is transforming the lives of various people. Since competition for manufacturing the various products is high, you may need to use CNC machines to withstand the heat.

You can join the winners’ league by buying the CNC machine to advance your manufacturing rate and enjoy the benefits thereof. You can say goodbye to your conventional machine and soar high with new profits from the proceeds of the improved processes.

We have expertise is in CNC manufacturing, rapid tooling, and more. Call us for more details.

Rocheindustry specializes in high quality rapid prototyping, rapid low-volume manufacturing and high-volume production. The services of rapid prototype we providing are professional Engineering, CNC Machining including CNC Milling and Turning, Sheet Metal Fabrication or Sheet Metal Prototyping, Die casting, metal stamping, Vacuum Casting, 3D printing, SLA, Plastic and Aluminum Extrusion Prototyping, Rapid Tooling, Rapid Injection Moulding, Surface Treatment finish services and other rapid prototyping China services please contact us now.

Related source links:

Benefits and Possible Alternatives of Aluminum CNC Machine

White Paper: The Ultimate Guide To CNC Machining

White Paper: The Ultimate Guide To CNC Router

Handbook: The Ultimate Guide to CNC Rapid Prototyping

Handbook: The Ultimate Guide to CNC Lathe Machine