Contents

Overview of CNC Router

There are various things out there on the planet that may astound us.

The massive technological advancement that we have been witnessing for quite a long while has to be sure given us some machining systems that have altered the manufacturing and assembling scenes.

One such method is the CNC Machining administrations.

In addition, it has likewise made numerous job open doors for talented CNC machining experts with more jobs being anticipated to be made in the following barely any years.

CNC machines are computer-controlled instruments that consequently move a device around a workpiece on a progression of tomahawks to perform cuts.

All CNC machines utilize subtractive assembling to make the final result, which means they work by expelling material from a current piece as opposed to by including onto it.

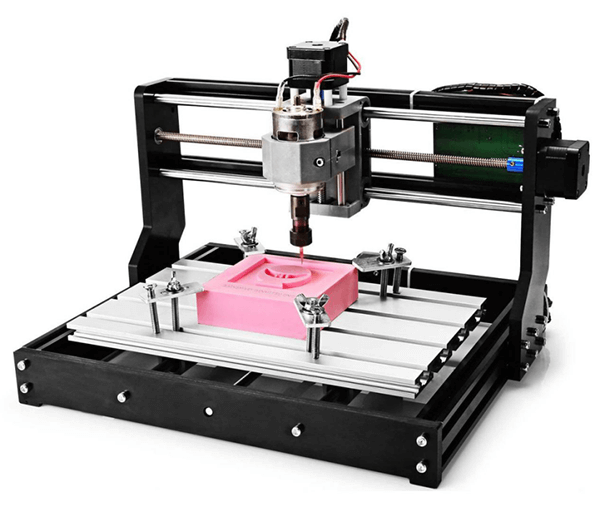

One of the CNC machining services that you should know is the CNC router. Read on as we tell you everything that you should know about the CNC router.

What is a CNC Router?

A computer numerical control (CNC) switch is a computer-controlled cutting machine identified with the hand-held switch utilized for cutting different hard materials, for example, wood, composites, aluminum, steel, plastics, glass, and foams.

CNC routers can carry out different tasks in carpentry shop machines, for example, the board saw, the shaft decay.

Rather than directing by hand, device ways are controlled by means of computer numerical control. The CNC router is one of the numerous sorts of apparatuses that have CNC variations.

A CNC router ordinarily delivers steady and excellent work and improves factory productivity. In contrast to a jig router, the CNC router can deliver an irregular as adequately as rehashed indistinguishable creation.

Its advantages incorporate automation, preciseness, a decrease of waste and errors, and the time the completed item takes to get the chance to showcase.

How a CNC Router Works

A CNC router works in a similar manner to a CNC machining. So, to properly understand how a router works, let’s have a brief overview of the CNC machining.

So, what is a CNC machining?

Computerized Numerical Control (CNC) machine is a method that is utilized to complete a variety of manufacturing activities and undertakings.

Every one of these assignments is performed utilizing computerized gadgets. Since the time the 1970s, Computer-Aided Design (CAD) and Computer Aided Machining (CAM) encourage the utilization of CNC procedure over the old fashioned manual machines.

The new-age machines are fully controlled by programming software that carries out plenty of undertakings with a higher level of accuracy, exactness, and proficiency. With the help of increasingly automated control, CNC machines can likewise help hugely in improving overall productivity.

CNC Router Process

The video below provides a summary of how a CNC router works:

The first step of how a CNC router works is by creating a 3D design of the object to be processed.

3D design process entails cutting something with a CNC is making a 3-dimensional object that you need to cut. Do this while keeping in mind that, the material that you are cutting from is three dimensional.

A 3D object is whatever takes space in three directions. For example, a piece of paper occupies a room in 3 directions. It extends left to right, front to back, and (albeit little) up and down.

If you already have a 3D CAD design, then you won’t bother going through the above first process.

The next step is the CNC machining process. In our case, it will be the routing process.

The last step in the CNC procedure is the actual cutting of material. This is where all your work on the computer at last springs up, and you can watch a clear bit of material change into the item you made.

This progression of the procedure is really the least demanding for the operator. Now, it’s dependent upon the computer to execute the code that the work made.

The operator should remain nearby to the machine to guarantee it doesn’t experience any issues, however generally, nothing ought to be required outside of keeping the territory around the machine clean.

A customary CNC router can move and cut in three ways which are typically alluded to at the X, Y, and Z bearings. The X-axis is typically the longest of the three running front to back. The Y-axis runs from left to right while the Z-axis runs here and there. Underneath, you can see every axis marked individually.

These machines are effective in that they work in each of the three directions close to consummate harmony, giving this machine the ability to cut complex shapes.

With the experienced CNC operators, the whole process of CNC routing should be smooth and successful.

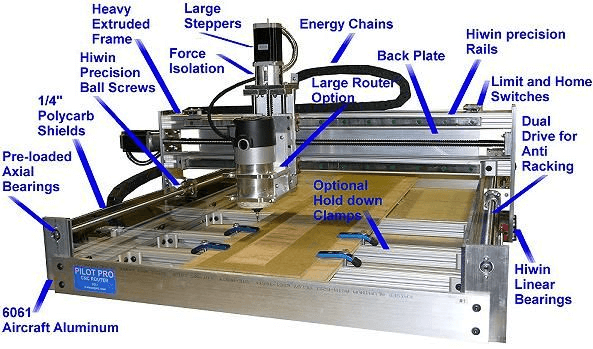

Components of a CNC Router Parts

To execute the processes above successfully, there are various CNC router parts that work together to deliver the desired success.

These components include:

Computer control system

The CNC router controller and computer system cooperate as the “brain” for these machines, telling the engines and drive system which course to move and how far. Obviously, the computer must be given a design.

Most designs start in a digital configuration, for example, a dxf drawing or some other comparative arrangement. The client would then utilize a CAM programming bundle alongside the CNC controller programming gave. These sorts of programming convert a 3D or 2D digital picture into a device way code, for example, G-code.

The computer at that point changes over these commands into a digital sign which it transfers to the CNC controller which changes over the digital sign to shifting voltages and flows that control the mechanical drive systems.

The greater part of this is unmistakably more than anybody working a CNC router would need to know. The UI will vary relying upon the sort or the manufacturer, however, the general procedure still remains the same across the board.

You start with a digital design and then utilize extra programming software for clearing device ways for the machine to follow.

CNC Router Spindle

The spindle is the piece of the machine doing the cutting. It does the actual routing, for example, a standard wood router. The router spindle is categorized by its power rating, strength in English units, and Watts in SI units.

The spindle works bye turning a cutting instrument, for example, switch bits, at different rates. A run of the mill spindle intended to cut wood plastics and other delicate materials, as a rule, have a scope of 8000 to 30,000 revolutions for each moment. Spindles intended to cut metals work somewhere in the range of 2000 and 10,000 RPMs.

Most CNC wood routers are fit for cutting metals too. Be that as it may, it is normally restricted to nonferrous metals, for example, aluminum.

When cutting metals or carbon-based composites at high spindle speeds, a coolant system that cools the material being cut and the apparatus itself is generally vital.

A few spindles are controlled through the CNC controller which directs the RPM dependent on material and the feed pace of the machine.

There are different accessory tools that might be introduced also, some of which incorporate a programmed device changer, apparatus sensor, and contact probe.

CNC cutting Bed

The cutting bed is the place all the activity occurs. The cutting bed may come in a few unique types, yet the capacity remains to be the same. The cutting bed is intended to help and secure the bit of material being cut.

There are a few distinct designs that do this viably. Probably the most widely recognized cutting bed structures cutting bed plans are the T-space and the vacuum table. The T-opening style table functions admirably for most parts as it utilizes jolts and clips to tie down the piece to the bed.

The vacuum table is found on numerous top of the line models and functions admirably for most companies cutting a similar plan a few times each day. In any case, it is constrained to generally level pieces, for example, wood and sheet material. The T-opening is increasingly flexible in that is can hold essentially any piece; however, needs effectiveness and speed of arrangement.

There are numerous different kinds accessible. Some are a half breed blend utilizing both a T-space and the vacuum structure.

CNC Drive Systems

Every axis utilizes a straight drive system that moves the shafts in that axis. The CNC straight drive system incorporates a motor, a direct bearing system, and a lead screw.

The motor is the connection between the mechanics and the hardware of the system. The motor gets power from the CNC controller giving rotational power when expected to the lead screw get together.

There are two kinds of motors found on CNC wood switch machines, which are stepper motors and servo motors. Steppers motors are the less expensive other option and offer great performance, and unwavering quality yet is generally not a closed loop system.

Servo motors offer a shut circle system, which implies subsequent to getting their bearings from the CNC controller, they send signals back to the controller that checks they have finished the intended task.

Summary

Ideally, at this point, you have a decent comprehension of how a CNC wood router or any CNC Router works.

The programmed computer provides orders to the CNC controller, which controls the motors.

The motors turn the straight drive system, which moves the spindles in 3 dimensions. The spindles turn cutting instruments quickly that carve the material being cut.

CNC Router vs. CNC Mill

Both the CNC router and the CNC mill are components of the CNC machinery. So, how can I differentiate between the two?

The table below provides a clear summary:

| CNC Router | CNC Mill |

| Used to cut softer materials like wood, plastic, and foam | Used to cut metals and tougher materials |

| Mounted on a stationary table with a larger workspace | Mounted on a stationary table with adequate space |

| Operates at high speeds | Slower operating speeds |

| Features a spindle that moves along X, Y, and Z axes | Move in an X-Y configuration |

| Uses rotational speed to make cuts | Spindle moves along a linear axis above the workpiece for increased clearance along Z axis |

Example of a CNC Router Service

Do you want to know about the CNC router service? We won’t hesitate to give you a clear demonstration using this example:

A perfect case of using a CNC router is to control wood. Many woodworkers use CNC routers to cut and shape a wide cluster of wood types. For example, in the event that you need to design a seat for your porch in the western U.S., you may decide to utilize a CNC router to cut the maple wood you have gathered for such a task.

By utilizing CAD and CAM programming on a PC, you can program the CNC router precisely how to cut the wood at exact points. You would then be able to take these recently cut bits of wood and use bolts or fastens to assemble them an agreeable and rural yard seat.

Applications of CNC Routers

It tends to be utilized for a huge scope of materials, for example, woodcutting, MDF cutting, plastics cutting, froths processing, and metals cutting. Contrasted with a physically worked router, CNC machines can cut at a significantly higher speed, make a lot of smoother edge completes, and produce a progression of indistinguishable items just as irregular pieces.

So, here are the most common applications of CNC routers:

1. CNC wood router for furniture and carpentry

Utilizing the CNC router machine is the best decision to create enormous amounts of furniture products. Furthermore, in the event that you need to transform your creative mind into the real world and make some special furniture. A CNC router is ideal for such kind of task. CNC router can deliver a wide scope of individual tailor furniture, including beds, feasting sets, seats, staircase, window, present-day furniture, office furniture, and so on.

2. CNC router for signage

The modern world signage is characterized by absolute refinement. The signs for advertising are more appealing to the eyes and seem to be well-curated.

CNC routing is one of the things that have contributed to such developments.

3D carvings, engravings, contour profiling, and V-bit carvings are just some of the products of CNC router for signage.

3. CNC Router for Molding and Prototyping

These days 5-hub foam factory CNC routers, huge gantry switch for foam milling,6 hub robotic arm,7 hub modern robots, are perfect for milling epoxy, foam, and dirt 3D configuration models.

CNC foam slicing cutting can be utilized to cut molds from EPS foam, polyurethane foam, EVA foam, plastic, and so on. They are extremely useful for building CNC foam molds and robot manufacture. Increasingly more advanced studio pick them for further processing.

4. CNC router for design

They are generally utilized architectural millwork. On account of the impeccable detail, a CNC switch can deliver, you can make complex designs for a wide range of one of a kind architectural contacts.

5. Arts and artwork

The scope of expressions and artworks you can deliver with innovative CNC router services is practically boundless, for example, jewelry, mirror and picture frames, coins, Christmas designs, and plaques.

6. CNC router for metal machining

Working with non-ferrous metals like aluminum and metal requires expanded cutting capacity from your CNC router machine – notwithstanding somewhat more consideration and readiness. Yet, when done appropriately, it can set aside time and cash in the shop while delivering a predominant outcome.

Deciding and using the best possible feed rate and spindle RPM turns out to be progressively significant when working with aluminum or metal as they associate a piece contrastingly with the blades than different materials.

7. CNC router in making musical instruments

The accuracy capacities of CNC routers are maybe never more vital than while making musical instruments. Each segment should be sliced to correct details and made to cooperate appropriately so as to deliver a wonderful scope of sounds.

CNC routers assist musical with instrumenting makers produce huge amounts of top-notch products on an effective course of events, never relinquishing the exhibition of the pieces anytime all through the procedure.

CNCs likewise exceed expectations in making exceptional instruments by means of one-time extends so producers can give clients a special outcome that meets their definite needs.

Advantages of CNC Router

As a manufacturer, you have every reason to take your parts and components for the CNC router services. Here are some of the benefits of a CNC router.

Accurate cuts

One of the significant advantages is their capacity to perform accuracy cuts. CNC routers are drive-by CAD programming that has made cutting troublesome and exact materials a lot simpler when contrasted and the customary manual cutting procedure.

Accuracy cutting carries with the additional advantage of less material waste, which thusly prompts more noteworthy investment funds and higher net revenues. Since a large portion of the work is electronic, the procedure is less work escalated, prompting lower labor costs.

Can be used on different materials

Some CNC routers can slice up to 30 distinct materials from wood to steel, froth, plastic, acrylic, and that’s only the tip of the iceberg. The individuals who need a single design to be cut over and over, these machines can deal with the procedure effortlessly and can be left unattended to keep the creation line moving.

Cost-saving

CNC routing can help to cut down the cost of production by a big margin.How is this possible?

First, the process is fully automated. This means that there is less human labor that is required to supervise the whole CNC routing process.

Secondly, the accuracy of the process means that there will be minimal wastage of the material when it is cut.

Also, the fact that you are outsourcing the service means that you won’t deal with everything that entails CNC routing.

Flexible and adaptable

Apart from just different materials, CNC can work on different types of designs. So, if you want to cut materials that have very complex shapes and designs, let the CNC routing take the course.

In case you want a different design to be cut, all that is needed is to update the software so that it fits the dimensions of the new design.

Time-saving

Do you have large volumes of materials that need to be cut within a short time frame? CNC routing is the ideal option.

It is designed to cut large volumes at a faster rate since the process is automated.

Do you want to enjoy the above benefits to the fullest? Just invest in quality CNC router services.

CNC Router Service in China: Roche Industry

Like other CNC machines, CNC routers are compelling at making exact materials. In any case, the most widely recognized areas where CNC routers are used to incorporate hobby activities like carpentry, making while at the same time they are used for making serious commercial products in the commercial aspect. In other words, we are simply saying that CNC routers are found in manufacturing fields, yet they can easily be bought for private use. One thing that we are all sure is they are incredible at producing whichever products that you want at the highest precision level.

Are you trying to make a product that you think will need CNC routers in one of the production? You better seek the services early enough.

We at Roche Industry specialize in providing top-notch CNC router cutting and engraving services near you. We are fully dedicated to meeting the needs of our customers.

In addition to having advanced CNC router machines, we also have the best technicians who can execute the job so easily and eloquently. No project is too complex for us to handle.

All you need is to contact us, and we will work together to fulfill your dreams.

Rocheindustry specializes in high quality rapid prototyping, rapid low-volume manufacturing and high-volume production. The services of rapid prototype we providing are professional Engineering, CNC Machining including CNC Milling and Turning, Sheet Metal Fabrication or Sheet Metal Prototyping, Die casting, metal stamping, Vacuum Casting, 3D printing, SLA, Plastic and Aluminum Extrusion Prototyping, Rapid Tooling, Rapid Injection Moulding, Surface Treatment finish services and other rapid prototyping China services please contact us now.

Related source links:

Benefits and Possible Alternatives of Aluminum CNC Machine

White Paper: The Ultimate Guide To CNC Machining

Handbook: The Ultimate Guide to CNC Rapid Prototyping

Handbook: The Ultimate Guide to CNC Lathe Machine

Handbook: The Ultimate Guide to CNC Manufacturing