The lathe is one of the oldest methods that have been used for manufacturing different types of products. It dates back to the 1300 BCE when the Egyptians used the bow-driven lathe for creating products.

The advancement of technology has resulted in a more sophisticated CNC turning process. This manufacturing technology is used in different industries. The parts and components that are created out of the CNC turning are accurate. There are many other benefits that come with this manufacturing technique.

In this post, I am going to take you through a complete guide to CNC turning.

Contents

What is CNC Turning?

The best way of defining this manufacturing technique is by splitting the two words. “CNC” and “Turning”.

Computer Numerical Control is a machining or manufacturing process that depends on the computer to machine a digital blueprint. CNC has made it possible for the manufacturers to fabricate complex parts and products within a short time.

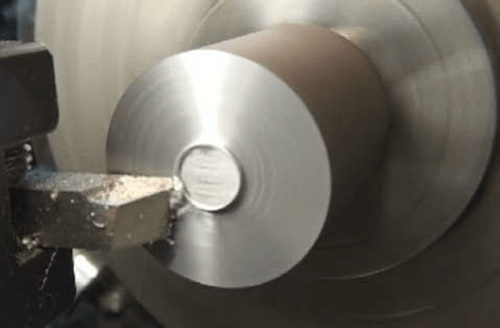

On the other hand, Turning is the actual process of using the lathe to remove materials from a larger workpiece.

In the past turning was done by humans but nowadays it is done by the computers through the CNC console.

So, what is CNC Turning?

This is an elaborate manufacturing process in which chunks of material are held in a chuck and are rotated as a tool is designed to cut and remove the material. As this happens a shape is created out of the original material.

The purpose of the CNC in this whole process is to control the turning and the cutting processes.

A turret that has tooling equipment is programmed to make consistent motions to the bar of the material. As it does so, it removes the material depending on what the CNC programming console dictates.

At the end of the process, you will have the shape and design that you wanted from the CNC turning.

How Does CNC Turning Work? Step by Step

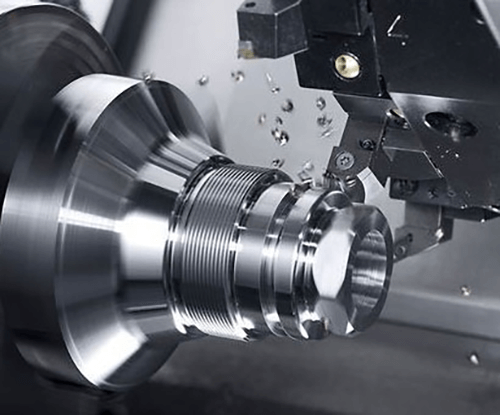

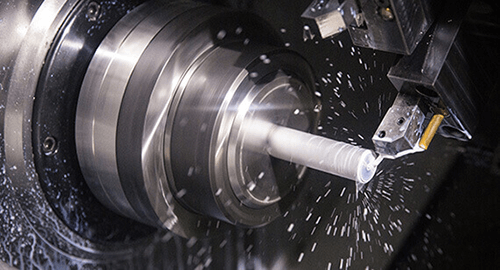

CNC turning is executed by CNC turning center which is sometimes referred to as ‘CNC lathe’. A CNC turning center is controlled by a computer hence has a high capability to perform sophisticated operations.

A typical CNC turning center is equipped with between 3 to 5 axes. It also has a couple of other tools that allow it to execute different operations such as turning, drilling, milling, and tapping.

Here are the steps of a typical CNC turning process:

1. The staring material that is fed into the CNC turning center is usually round-shaped. However, it can also have other shapes such as hexagonal.

2. The bar length can vary depending on the bar feeder. The length o the feeder will determine the volume of work done by the CNC turning center at any given period.

3. The CNC turning centers have a tooling equipment that is mounted on a turret. This equipment is controlled by a computer. There could be a pack of other tooling equipment that can further modify the material.

4. The capability of the CNC allows the operator to monitor and control the performance of the machine. In fact, modern CNCs have a ‘live’ tooling option whereby the operation can be monitored in real-time.

5. Once the turning is complete, you will be given your machined part. In case you would want to introduce new changes, feel free to talk to the company.

Before you consider having the CNC turning service, find out the capability of the CNC turning center. Does it have the right tools to execute the job?

Is my Part/ Product Fit for the CNC Turning?

Let’s say you have just heard of the CNC turning process. You are not sure whether it is the right manufacturing technique for your parts and products.

There are various ways of knowing whether CNC turning is the right technique for fabricating your parts.

Find out the largest OD for the part. The maximum OD for most CNC turning centers is 2.5”. However, you can still find some turning centers that can accommodate larger ODs.

The surest way of knowing the suitability of your parts is by seeking clarification from the CNC turning company. They are better placed to give you all the specifications that entail the process.

For instance, we at Roche Industry provide our clients with all the details regarding CNC turning. This way, you will have more confidence in the process.

Is CNC Tuning the same as CNC Milling?

Although CNC turning and CNC milling are closely connected, they are different operations.

CNC milling utilizes various commands to drill and cut metals along axes using the specified dimensions. The use of computer programs improves the accuracy of the process.

On the other hand, CNC turning uses computer commands to machine a final product. It uses a single cutting point.

CNC Turning Applications

CNC turning enjoys a wide range of applications in the modern world. It is always a method behind any metal-cutting environment as long as the metal is required to conform to some degree of the circular round shape. This applies to the components that have some kind of gear.

For the large-scale application, CNC is found in the automotive industry, aerospace, construction, agriculture, military, water vessels among others.

Some household and office equipment have parts that are made out of the CNC turning process.

Do you think that parts or your products need CNC turning? Talk to experts and they will advise you accordingly regarding the right process.

CNC Turning Services in China- Roche Industry

For years, we at Roche Industry have focused on providing quality CNC turning services in China. Ur desire to satisfy every need of our customers is what has propelled us to this position.

Our experienced CNC technicians are excellent at what they do. They are also creative and won’t hesitate to come up with the best designs. They deliver the best results within a short time.

We also boast of having high-end CNC tools that can execute the most complicated CNC turning tasks.

As a customer-oriented company, we are always happy to involve our clients in every aspect of the project. Feel free to contact us for the reliable CNC turning service in China.

Rocheindustry specializes in high quality rapid prototyping, rapid low-volume manufacturing and high-volume production. The services of rapid prototype we providing are professional Engineering, CNC Machining including CNC Milling and Turning, Sheet Metal Fabrication or Sheet Metal Prototyping, Die casting, metal stamping, Vacuum Casting, 3D printing, SLA, Plastic and Aluminum Extrusion Prototyping, Rapid Tooling, Rapid Injection Moulding, Surface Treatment finish services and other rapid prototyping China services please contact us now.

Related source links:

Benefits and Possible Alternatives of Aluminum CNC Machine

White Paper: The Ultimate Guide To CNC Machining

White Paper: The Ultimate Guide To CNC Router

Handbook: The Ultimate Guide to CNC Rapid Prototyping

Handbook: The Ultimate Guide to CNC Lathe Machine