Contents

What is Laser Welding?

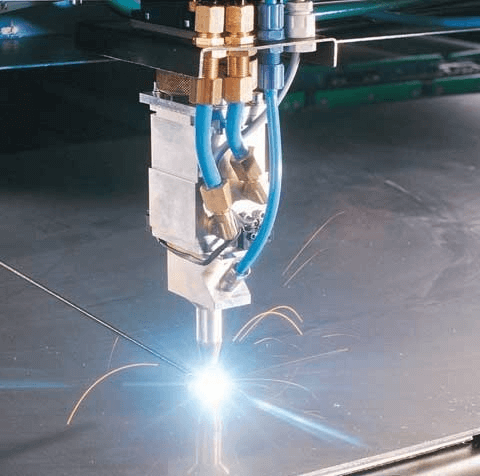

Simply defined, laser welding is a method in which a laser beam is used for joining two metals or even thermoplastics. Since the laser beam is a concentrated source of heat, the welding can be done at very high temperatures and within the shortest time possible. The laser beam also allows the welding of thick materials.

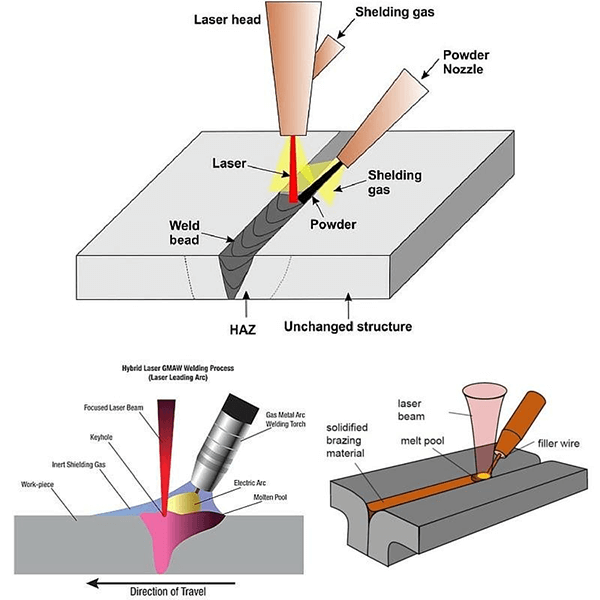

A typical laser welding is designed to operate in two modes. These are the conduction limited welding mode and the keyhole welding mode. The difference between these modes is based on the power and density of the laser beam.

A laser beam is known for having the highest concentration of energy. This is why it is able to work on different materials easily and effectively. The beam is uniform and operates at a single frequency.

Brief History of Laser Welding

Although welding, in general, may seem to be an old technology, significant developments in laser welding started in 1960 when a ruby laser was put into action for the very first time.

In the 1970s, performance-oriented lasers were developed, and they mainly relied on the CO2 lasers. From this, there have been numerous developments on laser beams.

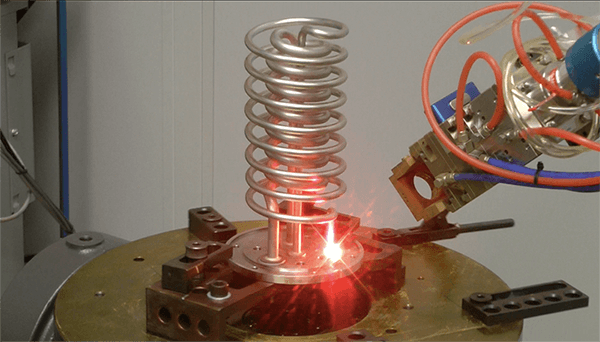

In the 1980s, laser soldering became a common thing whereby it was used for joining electronic parts on the circuit boards. The development of laser powder fusion started taking place during the same period.

It was until 2002 that Argon-CO2 gas started being used for laser welding. This gas increased the speed of laser welding and, at the same time, improved the accuracy of the whole process. It was also easy to change the direction of this gas combination.

Types of Lasers Used in Welding

There are three different types of lasers that are used for welding and cutting. These are gas lasers, solid-state lasers, and diode lasers.

Gas lasers utilize a mixture of gases such as nitrogen, helium, and carbon dioxide. They operate using low current high voltage power to excite the laser.

Solid-state lasers are divided into nd: YAG and Ruby’s lasers are stimulated to operate at constant high pulse energy.

Diode lasers, as the name suggests, generate the laser beam using the semiconductor diode.

How Laser Welding Works: Step By Step

The working principle of a laser welding process is not that complicated. There are distinct steps that are followed in the process.

1. A pump, which is the source of energy, supplies the needed energy for the process. This excites the laser to the extent that the electrons which are held by atoms are transformed to a higher energy level.

2. The electrons drop their energy levels drastically, and as they do so, they release photons. The spontaneous emission of the photons is what leads to the generation of the laser beams.

3. The photons that have been emitted spontaneously will strike other electrons that have a higher energy level. As they collide, the energy levels of these electrons will be lowered, leading to another group of photons.

The two groups which are now together will have the same wavelength and will move in the same velocity.

4. The photons will be emitted to all the directions. However, all of them are confined to travel along with the same medium so as to strike the resonator before they are reflected back through the same medium.

The resonator mirror will then define the level amplification and the direction of the emission.

For any amplification to take place, the percentage of atoms should be higher than that of the lower energy photons.

5. At this point, the laser is focused on the targetted workpiece that is to be welded. On the surface of the workpiece, a high concentration of light energy is converted to heat energy.

The heat will cause the surface to melt in a process known as surface conductivity. The beam of laser energy that is supplied on the surface is controlled to be below the vaporization temperature of that piece.

This laser energy is an ideal solution when working on the materials that have high thermal conductivity.

Apart from welding, other activities can be executed drilling, cutting, stripping, among others.

Advantages of Laser Welding

Whether you are into the manufacturing or assembling industry, what are the benefits of laser welding that you can enjoy?

Here are some of the chief benefits of using laser beam welding as opposed to other welding methods:

1. Maximum accuracy

One of the principal advantages of Laser welding is that it offers a significant level of precision and control.

The reality Laser innovation is so exact implies that it very well may be utilized to weld the smallest of parts together.

You will not have to worry about some mistakes that are caused by not being accurate.

2. Suitable for low heat application

The reality Laser welding innovation utilizes a low heat application, limits the contortion of the parts.

This is the reason it is the favored strategy for welding for those making delicate and treasured items, for example, bespoke adornments. Lasers utilize confined or concentrated heat energy.

This makes the method ideal for contact-free application, which protects the other sections of the welded components from the negative effect of heat.

3. Capable for complex joins

Laser welding technology is fit for taking care of entangled joins. Utilizing Laser welding innovation, you can weld different materials, just as zones, which would be too hard to even think about if you had opted for the conventional welding strategies.

4. Strong welds

Laser innovation permits manufacturers to make high quality welds. There is no requirement for a filler material to be utilized. Lasers give magnificent weld quality and clean preparation.

This is one of the reasons they are supported by manufacturers, especially in the medical business, where the safety of clinical gadgets and parts is vital.

5. Consistency and Repeatably

Manufacturers of different products pick laser welding as their main choice of welding strategy as it takes into account consistent and repeatable welds to be made.

It is a lot quicker welding system than other increasingly customary strategies and is likewise significantly more flexible.

A single laser welding machine can be utilized for cutting and drilling as well (Pulsed Fiber Lasers can likewise be utilized for stamping). The way that Lasers take into consideration phenomenal repeatability and are so adaptable assists organizations with making critical unit cost decreases.

What are the Limitations of Laser Welding

As much as laser welding may be an amazing technology, It also has some limitations. One of the most common disadvantages is the cost of welding.

Laser welding machines are very expensive hence are out of reach or many people. As a manufacturer, the cost of the machines alone can change your mind.

The good news is you can simply hire laser welding companies near you for assistance.

Laser welding companies have the best equipment for the job.

Another disadvantage of laser welding is it requires highly skilled labor. Most manufacturers are not ready to hire a specialist. Again, you simply need to contact a laser welding company that has experts to handle your project.

Otherwise, laser welding technology is almost flawless. As you can see, the few limitations of this technology can be easily worked on as long as you get the best laser welding manufacturer in China.

Metals Used for Laser welding

Laser welding is a versatile procedure that can be used for different welding types of metals. Some of the metals that are commonly used in the laser welding include;

Carbon steel

Aluminum

Titanium

Nickel

Stainless steel

Molybdenum

Kovar

Further advancements have been made in this technology with the aim of broadening its scope. It can now be used for many other types of metals and even different materials.

Do you have material but not sure whether it can be processed through metal welding? Seek expert’s advice on metal welding, and you will be advised appropriately.

Laser Welding Services in China- Roche Industry

Roche Industry offers a suite of quality and flawless laser welding services in China. This is our specific area of specialization.

Truth be told, we offer various exceptionally particular laser welding process to the full satisfaction of our clients. Our clients are from different industries, including sensitive ones such as aerospace and medical industries.

Our laser welding services are designed to allow exceptionally accurate welding inside a hermetically fixed space. This eliminates any chances of contaminant getting into your product.

Moreover, Roche Industry offers an assortment of laser welding services that will meet your specific interests.

CO2, nd: YAG, and fiber lasers are on the whole accessible for the daily welding applications. Lasers from 200–2,500 watts are administered by our expert laser welding engineers.

As a reputable laser welding company in China, we have the right tools and facilities to deliver. We are always available and geared to give you premium laser welding services in China.

Rocheindustry specializes in high quality rapid prototyping, rapid low-volume manufacturing and high-volume production. The services of rapid prototype we providing are professional Engineering, CNC Machining including CNC Milling and Turning, Sheet Metal Fabrication or Sheet Metal Prototyping, Die casting, metal stamping, Vacuum Casting, 3D printing, SLA, Plastic and Aluminum Extrusion Prototyping, Rapid Tooling, Rapid Injection Moulding, Surface Treatment finish services and other rapid prototyping China services please contact us now.

Related source links:

Everything You Need To Know About Different Types Of Welding

Essential Design Tips You Should Know About Welding Sheet Metal

The Basics of Bending Sheet Metal You Should Know

Everything You Should Know About Aluminum Sheet Metal

White Paper: The Complete Guide To Sheet Metal Fabrication

Handbook: The complete Guide to Laser Etching

Handbook: The complete Guide to Laser Drilling