This step by step guide will help you understand various approaches of cutting polycarbonates, including the necessary tool to use.

But before we delve into the main subject, it would serve right if we understand what polycarbonate is.

Contents

What is polycarbonate?

Polycarbonate is one of the forms of plastic that is transparent, sturdy, and resistant to both heat and impact. Polycarbonate is commonly known for its high thermal stability, transparency, and robustness.

Because of these attributes, polycarbonates are mostly used to make a wide variety of materials that are resistant to impact and transparent. The materials made from polycarbonate include greenhouse windows, eyewear lenses, and protective gear.

Unlike most types of plastics, polycarbonate can be easily formed at room temperature since it is flexible.

The process of cutting polycarbonate

There are many ways of cutting polycarbonate and using a wide variety of tools. Here are some methods of cutting polycarbonate.

1. Using a table saw to cut polycarbonate

Table saw is most effective for cutting polycarbonate that is more than 0.5 inches thick. It gives a more precise and clean-cut than most tools. Here is the process.

- Measure and mark your cut on the polycarbonate.

- Frame the mark using masking tape.

- Mount your table saw on a fine-toothed saw blade.

- Using the fine-toothed blade, cut the polycarbonate by pushing it through the saw the same way you would push plywood.

- Do not exert too much pressure when pushing the polycarbonate to avoid cracking.

- Repeat the procedure until all your polycarbonate is cut.

A fine-toothed blade is used because it is the most appropriate type of blade for giving polycarbonate a clean and precise cut.

2. Using a band saw to cut polycarbonate

A band saw is cutting equipment that is mounted on a table. It works pretty well in cutting polycarbonate of any width. Cutting polycarbonate using a band saw requires a fine-toothed blade of between 10 and 18 teeth per inch.

- Mount the blade on the saw and set the cutting sped of 2500 PRM and above.

- Push the polycarbonate steadily through the saw, stopping only when the cutting is done.

Like a table saw, cutting polycarbonate using a band requires a fine-toothed blade for precision.

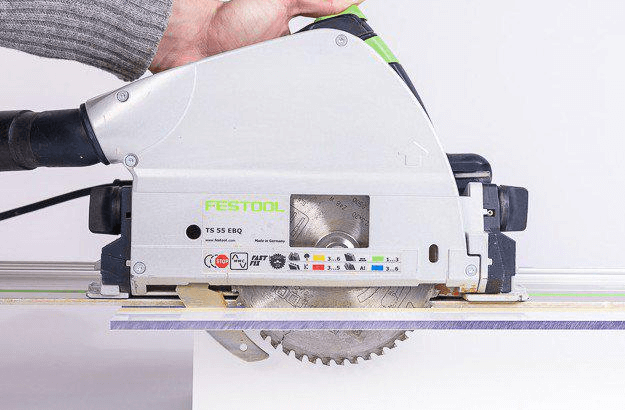

3. Using a circular saw to cut polycarbonate

A circular saw is one of the most effective tools for cutting materials to produce perfect finishes. A circular saw can cut through polycarbonate of about 0.125 to 0.5 inches. Cutting thinner polycarbonate using a circular saw requires the use of a hollow ground panel blade (at least ten teeth per inch). Heavy gauge polycarbonate requires a triple chip cut carbide blade with alternating bevel and straight teeth (at least three teeth per inch). Here is the procedure.

- Mount the blade you are going to use on the saw.

- Clamp the polycarbonate to the sawhorse or any other cutting support of your choice.

- Grasp the saw with both hands and push it slowly through the polycarbonate to make your cut.

- Make sure that you use moderate force when pushing the saw through the polycarbonate.

Circular saws can only be used to cut polycarbonates through straight lines. Cutting curves require either a band saw or a jigsaw.

4. Using a jigsaw to cut polycarbonate

A jigsaw is the best tool for cutting curves and designs out of any polycarbonate.

- Lay the polycarbonate on a cutting surface.

- Press the saw shoe on the polycarbonate then direct the blade thou it to cut.

- Like any other cutting equipment, use moderate force when pushing the saw through the polycarbonate.

When cutting curves and designs, you should move the blade from curves to the inside corner. Additionally, guide the blade through the marks made on the polycarbonate. You can also use relief cuts to reduce wastage when cutting through tight curves.

5. Using CNC Router to cut polycarbonate

A CNC Router is the equipment used to cut materials using computer technology. It works with the help of a computer program called CAD. Due to the technicality of this tool, it offers the most precise and accurate cuts than any other manual device.

- Cutting polycarbonate using a CNC router requires some basic knowledge about the CAD software.

- Create input command into the computer program.

- The command shows the router was to cut through the polycarbonate.

- Place the polycarbonate on the equipment (router table) and let it run through the desired shapes you have put into the CAD software.

- You may have to hold the polycarbonate on the table as the router does the rest of the work.

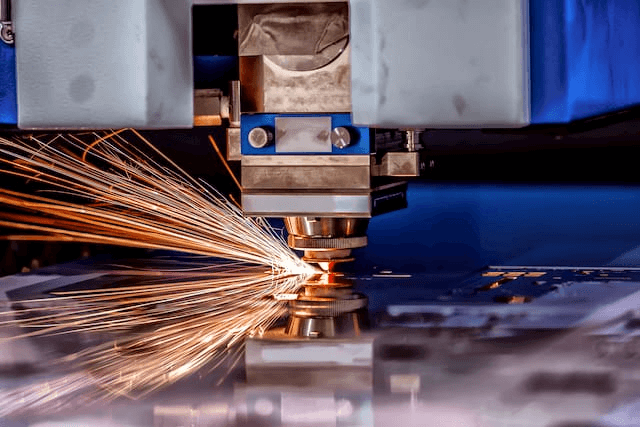

6. Using a laser to cut polycarbonate

Lasers are powerful optical beams that can slice through any object as long as it is designed. How do laser cutting works? Check below.

- Mark the polycarbonate to indicate how you want it cut

- Place the polycarbonate on a surface you don’t mind cutting or clamp it suspended to avoid cutting through surfaces.

- Direct the laser beam through the polycarbonate following the marked parts that you want to cut.

Laser cutting also produces the finest cuts on polycarbonates and other materials. You may want to adjust the intensity of the beam to cut through thicker polycarbonate.

The only drawback of using laser cutting is that the entire process is very costly.

Wrapping it up

Cutting polycarbonate is not an overwhelming task. However, it requires a lot of caution. Putting safety first should be a priority when using the tools listed above. Additionally, it is essential to use the right blade for any given thickness to avoid damaging the polycarbonate.

Blunt blades can also cause a lot of wastages. It is recommended to check the instructions that come with the tools used to cut polycarbonates. Lastly, the key to getting a clean cut is making marks on the polycarbonate first and following through the targets with the blades as slow as possible. Remember not to use too much or too little force when cutting polycarbonate.

Related source links:

Handbook: Everything you need to know about PETG

PETG vs ABS: What are the Differences?

PETG vs PLA: What are the Differences?

Polycarbonate vs Acrylic: What are the Differences?

Nylon vs Polyester: What are the Differences?

Trivex vs polycarbonate: What are the Differences?

White paper: The Complete Guide To thermoforming

Everything You Need to Know about PVC Pipe Sizes

Rocheindustry specializes in high quality rapid prototyping, rapid low-volume manufacturing and high-volume production. The services of rapid prototype we providing are professional Engineering, CNC Machining including CNC Milling and Turning, Sheet Metal Fabrication or Sheet Metal Prototyping, Die casting, metal stamping, Vacuum Casting, 3D printing, SLA, Plastic and Aluminum Extrusion Prototyping, Rapid Tooling, Rapid Injection Moulding, Surface Treatment finish services and other rapid prototyping China services please contact us now.