Stainless steel is among the most used materials in the world because of its wide range of features such as strength, resistance to corrosion, and durability. Thus, considering its strength and durability, one will be forgiven for being overwhelmed when it comes to cutting stainless steel. Fortunately, there are many ways one can use to cut stainless steel, and this article explores some of the best techniques. So, if you want to learn how to cut stainless steel, you are in the right place.

Contents

The tools needed to cut stainless steel

Stainless steel comes in a wide variety of forms and gauge. In most cases, the gauge of stainless steel determines its thickness. The tools you need to cut stainless steel depending on how thick your steel is. Here are some tools required.

- Tin snips (suitable for thin pieces of sheets)

- Power sheers (suitable for cutting thicker pieces of stainless steel sheet)

- Circular saw

- Angle grinder (suitable for thicker pieces of stainless steel sheet or tube)

- Plasma cutter (suitable for extremely thick stainless steel bars, sheets, or tubes)

Additionally, you require the following for safety and enhancing the cutting process.

- Face shield or safety goggles

- Protective work gloves

- A flat working surface, preferably a bench

- Tape measure and a marker

- A metal file

How to Cut Stainless Steel step by step

Step 1: Get Your Workplace Ready

The first thing you should do is to prepare for your workplace. It does not matter how you want to cut the stainless steel. For this step, you need sturdy sawhorses or a flat surface like a workbench.

If you want to use a grinder, saw, or a plasma cutter to cut stainless steel, you need free space, or you can work outside. If you are working indoors, then ensure there is nothing flammable within the room.

Step 2: Measure Your Cut

You should use a tape measure to give your material an accurate measurement of regions you want to cut. After that, use a marker to mark the areas you want to cut. This step helps to make the cutting precise and accurate.

Step 3: Cut the Stainless Steel

Once your workplace is ready, and you have measured and marked the regions of stainless steel you want to cut out, the next step is to decide on which tool you want to use. You can refer above to see which device is suitable for specific size (thickness) of stainless steel. Let us see how each of these tools can be used to cut stainless steel.

Using Tin Snips to Cut Stainless Steel

If you want to cut a thin piece of stainless steel, especially sheets, using a pair of tin snips is the best option. Place the tin snip on the edges of the sheet the same way you use a pair of scissors and slowly cut through the mark you made using a marker. This method is most effective if you want to make a straight cut.

Using Power Shears to Cut Stainless Steel

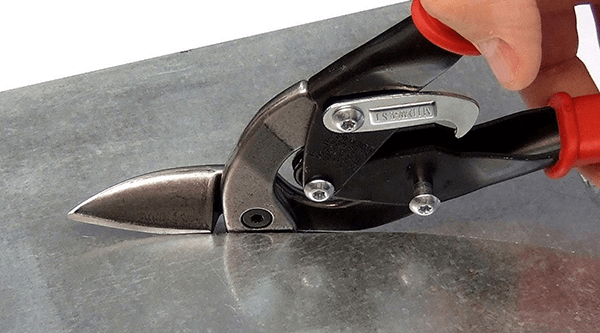

A pair of power shears will work the same way as a pair of tin snips. The only difference is that power shears have a motor. This tool chops off a slim strip as it cuts (as seen in the image above).

Get the steel between the jaws of the power shears and slowly move it along the mark you created while pressing on the trigger.

Using a Circular Saw to Cut Stainless Steel

A circular saw is an essential cutting tool that can be used to cut thick steel and other materials that are too thick for both tin snips and power shears. You only require the right blade, and your work will be effortless. Safety precaution is also an essential aspect when using a circular saw. For that case, you need to have a full face shield or protective goggle and heavy-duty working gloves. Additionally, you may want to protect yourself from metal splinters by wearing long sleeves and pants.

Once done, turn on the circular saw and let reach maximum RPM. Next, lower the saw with the blade moving on the surface of the stainless steel following the marks you made.

Using an Angle Grinder to Cut Stainless Steel

An angle grinder works the same way as a circular saw. So, you need to follow the same processes.

Allow the grinder to reach maximum RPM after turning it on. Move the blade slowly along the mark you made on the stainless steel.

Using a Plasma Cutter to Cut Stainless Steel

Plasma cutter is an advanced cutting tool that can be used to cut through any metal with less hassle. The device may not be as effective on thinner sheets of steel as it is on thick pieces of stainless steel.

The first you need to do is get the plasma cutter ready for the job. This process involves connecting the plasma cutter to an air compressor and turning on the air. The next step is to get the current setting right. Thicker metals require a higher current on the plasma cutter. For instance, a piece of stainless steel with a gauge between 18 and 20 will need a current of around 25 units. After setting the current, clamp the edge of the stainless steel.

Now that everything is set, you can turn on the machine and bring the torch handle closer to the metal. Press the trigger and trace the line you made with a marker to make your cut. Remember to do this slowly for precision.

Once done, shut off the plasma cutter and then disconnect the air compressor.

Step 4: Clean Up the Edges of your Metal

You have to understand that almost all of these tools leave some rough edges when done cutting. You need to use the metal file to give your metal a fine finishing along the cut edges.

The bottom line

Learning how to cut stainless steel step by step is not as hard as most people may think. You only need to have the right tool for the job, and that depends on the thickness of your stainless steel. Regardless of the technique and device you use to cut stainless steel, it is essential to put safety first by working slowly and having protective gear like a pair of gloves and goggles.

Related source links:

How to Remove Scratches from Stainless Steel

How to drill stainless steel step by step

How to polish stainless steel? (The Complete Guide)

Rocheindustry specializes in high quality rapid prototyping, rapid low-volume manufacturing and high-volume production. The services of rapid prototype we providing are professional Engineering, CNC Machining including CNC Milling and Turning, Sheet Metal Fabrication or Sheet Metal Prototyping, Die casting, metal stamping, Vacuum Casting, 3D printing, SLA, Plastic and Aluminum Extrusion Prototyping, Rapid Tooling, Rapid Injection Moulding, Surface Treatment finish services and other rapid prototyping China services please contact us now.