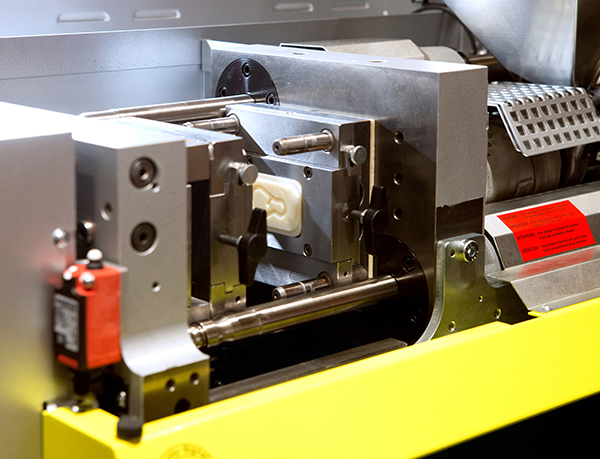

Injection moulding is a manufacturing process for producing parts by injecting molten material into a mould, or mold. Injection moulding can be performed with a host of materials mainly including metals (for which the process is called die-casting), glasses, elastomers, confections, and most commonly thermoplastic and thermosetting polymers. Material for the part is fed into a heated barrel, mixed (using a helical screw), and injected into a mould cavity, where it cools and hardens to the configuration of the cavity. After a product is designed, usually by an industrial designer or an engineer, moulds are made by a mould-maker (or toolmaker) from metal, usually either steel or aluminium, and precision-machined to form the features of the desired part. Injection moulding is widely used for manufacturing a variety of parts, from the smallest components to entire body panels of cars. Advances in 3D printing technology, using photopolymers that do not melt during the injection moulding of some lower-temperature thermoplastics, can be used for some simple injection moulds.

Are you looking for injection molding companies in Singapore? We have compiled the best 10 injection molding manufacturers list for you to pick as below:

Contents

Dynamold Precision Pte Ltd

Dynamold Precision Pte Ltd is a high quality thermoplastics injection mold manufacturing located in Singapore. We are a privately held company that was established

in 1999 and expanded into Malaysia (JB) in 2008.

We are principally engaged in the design and fabrication of plastic injection moulds. We manufacture plastic injection moulds for consumer electronics, computer

peripherals, telecommunications and other industries.

Dynamold has earned the recognition as a company that manufacturing highly precision quality injection molds through years of hard work, dedication and

commitment.

The key elements of our success are our high quality, cost competitive and shorter lead time.

Dynamold ultimate goal is to be able to provide our customer with ‘best in class’ quality, delivery and services…GUARANTEED

Address: North Spring Bizhub, 9 Yishun Industrial Street 1, #02-81/82, Singapore 768163, Singapore

Cosmag Plastic Mould Pte Ltd

Cosmag Plastic Mould Pte Ltd started in “Year” . Within a short span of time it has achieved a unique position in the market due to the combination of technology, attention to quality and acquired expertise. The company designs manufactures high precision injection moulds ranging from 20 Tons to 1500 Tons. The making of mould requires the highest level of precision. Every minute detail is computer aided. Our systems ensure the highest possible degree of precision. The high speed machining with ATC Technology gives maximum efficiency to our manufacturing process. Our skilled workmanship ensures the maximum quality excellence and customer satisfaction. We provide our service with lead-time so as to support in achieving fast time to market. .

Our commitments to clients has always been a top priority in our business. We recognize customer requirements and respond to them quickly. Before the despatch of the mould its performance is tested under realistic conditions.

Address:Block 50 #03-11, 50 Kallang Bahru (S)339334, Singapore 339334

Yin-Shan Engrg Pte Ltd

Yin-Shan Engineering Private Limited first started off in 1976 and started out from its humble beginnings as a sub-contractor in the precision plastic injection molding industry in Singapore.

Today, after 30 years of experience, we have successfully positioned ourselves as an established and reliable partner that offers one-stop turnkey engineering service in Product Design, Precision Tool Fabrication and Plastic Injection Molding.

Being dynamically able to achieve economies of scale, we are thus the ideal business partner for you in terms of costs, product quality and a dependable business partner.

Address: 1004 Toa Payoh N, #02-05/07, Singapore 318995

MAP Plastics Pte. Ltd

Established in 1988, MAP Plastics Pte Ltd is a well-known one-stop manufacturer of high-precision tools and injection moulded plastic components in the MedTech industry. Our clients in Singapore and other ASEAN countries attest to our trusted and reliable solutions that led us to have strong foothold in the country’s MedTech supply chain. As we reach over 30 years of practice in the industry, we embark on another fruitful journey with our plans to expand operations to USA and Europe.

Address:11 Loyang Ln, Singapore 508928

Tai Wai Plastic & Metal Moulding Co

Tai Wai Plastic & Metal Molding Company is an established company with more than 30 years of experience in making plastic injection and electronic component moulds.

Our production includes the designing and manufacturing of all kinds of precision metal and plastic moulds.

Tai Wai also specializes in die-casting, metal piercing and blowing. Our company has obtained certification in the ISO 9001 standards and aims to deliver to our customers only the best products and services.

Address:1003 Toa Payoh Industrial Park, Singapore 319075

Kay Kay Plastic Industries Pte Ltd

Kay Kay Plastic has been in the Plastic Injection Moulding business since 1992. Our current Singapore Based factory sits on about 12,000sqft of working space. It all started with only 10 employees but we have grown to about 40 employees now.

With the competitive precision engineering industry, maintaining high quality standards through numerous certifications and practices is our strong hold.

Adopting the Japanese way of continuous improvement through 5s and Kaizen has helped our company to level up.

Address:28 Kallang Pl, #02-01 to 09, Singapore 339158

Meiban Mold Manufacture Pte Ltd

Meiban Group is an EMS provider with capabilities ranging from design and development, in-house mold making, plastic injection molding, PCB production and assembly to full product assembly.

Meiban has more than 30 years of experience as one of Singapore’s top contract manufacturers based in Singapore, Malaysia and China. Like us, our customers are global brand owners who are committed to excellence and quality. Here at Meiban, we aim to create value-added services with the lowest possible cost, making us a cost leader in our field.

Come shape your ideas with us. We live to make your business a success.

Address: 26 Ang Mo Kio Ind Park 2, Singapore 569507

Inzign Pte Ltd

Inzign is Singapore’s leading plastic injection molding contract manufacturer. Specialising only in disposable medical and healthcare devices, Inzign aims to be the healthcare sector’s preferred manufacturer both in Singapore and abroad.

Inzign believes in producing only high quality tools that are designed and built to work effectively. Inzign assures delivery on schedule and at competitive prices. Being both design oriented and customer-oriented, Inzign welcomes challenges in producing ever more complicated parts while reducing costs to meet the customer demands.

Inzign added to its manufacturing capabilities by partnering Singapore’s leading manufacturing technology research institute (SIMTech) to serve the fast growing lab-on-chip / microfluidics industry.

Address:16 Kallang Pl, #02-10, Singapore 339156

Husky Injection Molding Systems Singapore Pte Ltd

As the largest brand-name supplier of injection molding equipment and services to the plastics industry, we are engineers, designers, innovators, material and software specialists, and problem solvers. Team Husky comprises more than 4,300 dedicated people worldwide, focused on building success and profitability for our customers, who operate in over 140 countries.

Our headquarters and main manufacturing facilities are located in Canada, with additional manufacturing facilities in the U.S., Luxembourg, Switzerland, China and the Czech Republic. Plus, three technical centers in Japan, Luxembourg and Shanghai, as well as a global network of locations.

Address:80, Changi Road #A-15 and #05-15 CentroPod, Singapore 419715

Omni Mold

Omni Mold company, is a ultra precision plastic injection mould making company in Singapore. Specializing in ultra-precision, high complex and high cavitation moulds. Our state-of-the-art facility is equipped with advanced computer software and machine tool hardware. Together with proven track records, system and highly trained staffs, we are positioned to meet the requirements of the most stringent customers in the global arena, in sectors such as Medical, Pharmaceutical, Healthcare, Nutrition / Food Packaging, Information Technology, Office Automation, Automotive and Consumer Electronics.

Address:51 Joo Koon Circle, Singapore 629069

Conclusion

How to choose right injection molding services company is very important, Without looking further, we’re also injection molding services company in China. Rocheindustry aim to give purposeful reviews and information that is bound to save your time. In case of any questions, inquiries, or even comments, reach out to us.

If you’re looking for injection molding services with competitive price in China please contact us as below button.

Related source: Handbook: The Complete Guide To Injection Molding