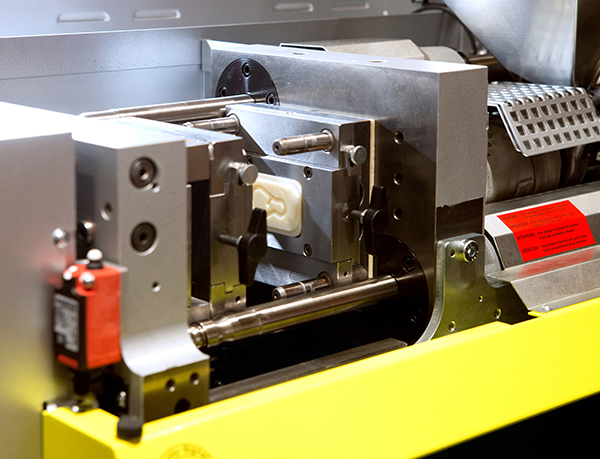

Injection moulding is a manufacturing process for producing parts by injecting molten material into a mould, or mold. Injection moulding can be performed with a host of materials mainly including metals (for which the process is called die-casting), glasses, elastomers, confections, and most commonly thermoplastic and thermosetting polymers. Material for the part is fed into a heated barrel, mixed (using a helical screw), and injected into a mould cavity, where it cools and hardens to the configuration of the cavity. After a product is designed, usually by an industrial designer or an engineer, moulds are made by a mould-maker (or toolmaker) from metal, usually either steel or aluminium, and precision-machined to form the features of the desired part. Injection moulding is widely used for manufacturing a variety of parts, from the smallest components to entire body panels of cars. Advances in 3D printing technology, using photopolymers that do not melt during the injection moulding of some lower-temperature thermoplastics, can be used for some simple injection moulds.

Are you looking for injection molding companies in the USA? We have compiled the best 10 injection molding manufacturers list for you to pick as below:

Contents

USA Injection Molding

USA Injection Molding, a division of LMT Mercer Group, Inc, is a full-service plastic injection molding facility that makes it possible to design, manufacture and distribute products in the USA. Because we offer all of these services under one entity, we can provide existing manufacturers an all-in-one design to distribution solution to grow and improve their businesses.

Whether you have existing tooling or need us to help you with your design, we are ready to partner with you. From design to distribution, we will be with you every step of the way. We provide part design services, production, assembly, packaging, bulk shipments and fulfillment from our US warehouses. Our dedicated Customer Service and Sales teams ensure that our customers receive individual attention and care throughout the entire process.

Headquartered in Lawrenceville, NJ, we operate manufacturing plants in New Jersey and Ohio. Our distribution centers are located in New Jersey, Ohio and Nevada, therefore, we are able to control shipping costs. We specialize in the design and manufacture of single and multi-cavity molds. We use high-cavitation tooling and operate 36 state-of-the-art injection molding machines, with servo-robotics and nitrogen gas-assist capabilities. They range from 60 to 1,000 tons.

USA Injection’s parent company, LMT Mercer Group, Inc., was formed in 1987 to supply the fence and deck industry with high-quality component parts. Today, we are the largest manufacturer of fence, deck and railing accessories to the US and Canada with more than 950 products. Additionally, we now serve all industries that use plastic injection molding products and components. We manufacture a broad range of products designed to meet the needs of a diverse and demanding customer base, introducing at least twenty (20) new products each year.

Address: 109 NJ-31 North, Pennington, NJ 08534, USA

Veejay Plastic Injection Molding

Since 1970, Veejay Plastic Injection Molding has demonstrated integrity and commitment to exceeding our customers’ expectations by providing fast service, on time delivery and high quality custom injection molded parts. Our experience, innovation and quality-driven products are what set us apart from our competitors

For over four decades, we have been custom molding plastic parts using various thermoplastic resins including, for example, PEEK, ULTEM, Vectra , ZENITE as well as other resins like NYLON, ABS, POLYCARBONATE( LEXAN), PBT (VALOX), unfilled or filled with glass fiber, glass beads, and carbon fiber. We have the ability and knowledge to run a wide variety of materials to meet special applications. This is why Veejay Plastic Injection Molding Company is the right choice to help our customers succeed.

We know that you have choices when it comes to injection molding companies but you will not find anyone else more dedicated to producing top quality components to help your business thrive. With Veejay Plastic, you will receive personalized service and attention to detail to ensure your satisfaction.

Address: 395 S Main St, Burlington, IL 60109, USA

The Rodon Group

The Rodon Group is an ISO 9001:2015 certified, high-volume, custom plastic injection molder.

We offer a turnkey and innovative manufacturing solution including mold design, mold building, and high-volume parts manufacturing. Our globally competitive prices eliminate the risks of sourcing offshore. With over 125 plastic injection molding presses, The Rodon Group is one of the largest family-owned and operated injection molders in the United States. We serve a diverse group of industries including consumer products, windows and doors, medical and pharmaceutical, construction and food and beverage.

Address:2800 Sterling Dr, Hatfield, PA 19440, USA

Plastic Molding MFG

Plastic Molding Manufacturing is your manufacturing solution company for polymer-based products.

We focus on plastics molding development, thin and thick wall molding, tight tolerance molding, part joining, and assembly.

We serve multiple markets, including: Industrial, Medical, Electronics, Defense, Transportation, and Consumer.

Our mission is to honor manufacturing by providing economic growth, employment, and production resources in the United States.

Address:34 Tower St, Hudson, MA 01749, USA

Autronic Plastics Inc

Founded in 1953, Autronic Plastics, Inc. (API) has grown from a small plastic molding company to an industry leading, custom injection molder known for its service, creativity, technology, and commitment to excellence. In its early years, API developed solutions to problems for specialized markets in life safety products and office equipment.

Today, API is a manufacturer for many different technologically advanced markets, including the medical and dental, automotive, life safety, lighting, aerospace, military, defense, and consumer product industries. API’s expertise in processing high performance engineering resins and manufacturing high quality, precision parts has made us the plastic injection molding OEM (Original Equipment Manufacturer) of choice for many of our customers. API provides turnkey solutions for many customers and is proud to be one of the top New York contract manufacturers. We are proud to announce that API recently opened their new corporate headquarters, a 100,000 sq. ft. facility in Central Islip, NY, to continue our growth as a Long Island plastic manufacturer. The ISO 9001:2015 certified facility is the new home of API’s corporate headquarters, design & engineering, tooling, manufacturing, assembly, and distribution.

Address: 29 New York Ave, Westbury, NY 11590, USA

Rex Plastics Inc

Rex Plastics is a second-generation, family-owned and operated full-service plastic injection molding contract manufacturer founded in 1971 by Rex Clark. As a former machinist for the Navy that started the company in his pump house with one machine, Rex landed a customer making emergency vehicle antennas by hand in his second year of business, and we still mold for that customer today. Rex Plastics is run today by two sons, a niece, and a nephew who carry on the rich tradition of accessibility and customer advocacy the organization was built around.

Address: 12515 NE 95th St, Vancouver, WA 98682, USA

Bennett Plastics Inc

Operating since 1982, Bennett Plastics has been a plastic injection molding company in greater New York area with the best plastic injection molds in the industry. Located just minutes from New York City in Paterson, New Jersey, we are privately owned and manufacture millions of parts each year in our 36,000 square foot facility.

Address: 22 Kentucky Ave, Paterson, NJ 07503, USA

Plastic Design International Inc

Plastic Design International, Inc. started in 1977 in the short-run prototype R&D business. Over the years we’ve harnessed our expertise to evolve into your complete injection molding resource center.

We’ve got all of the tools needed to take your companies’ project from initial concept to final molding and assembly.

Two locations with a total of 55,000 square feet.

21 molding machines with a 35 Ton to 385 Ton capacity.

ISO Certified with a fully documented Quality System.

The latest in innovative technology, including robotic sprue pickers, automated conveyors and CMM equipment.

A central tracking system for order entries, Material Requirement Planning (MRP), inventory control, scheduling and shipping.

With PDI as your plastic injection molding company, you will always meet your supply requirements.

We are a manufacturer of injection molds, plastic parts, and components for a wide variety of applications.

Address:111 Industrial Park Rd, Middletown, CT 06457, USA

Hicks Plastics Company

For over 30 years, the Hicks Plastics Company has been building lasting partnerships with both automotive and non-automotive customers. Hicks Plastics is a leading manufacturer of injection molded and vacuum metallized components with plants located in Macomb Township, MI and Knoxville, TN.

With vacuum metallization expertise dating back to the summer of 2000, we have developed a highly efficient and robust sputter coating manufacturing process allowing direct metallization to molded substrates with in chamber HMDSO topcoat capabilities. This process allows us to offer our customers very attractive pricing and a broad spectrum of finish capabilities to provide cost effective differentiation and customization options.

At Hicks Plastics, we have implemented a highly automated injection molding process with computerized material handling and resin drying systems with robotic de-molding. This allows us to provide injection molded products with superior Class A surface finishes that are required to provide vacuum metallized products with world class quality appearance finish.

Hicks Plastics is an ISO/IATF 16949 registered supplier that is committed to meet or exceed both the quality and customer service expectations of our customers and deliver on time, every time. If your product requires very tight tolerances, that is not a problem. We have 21 electric injection molding machines that have a very precise molding accuracy and the repeatability to consistently operate within an extremely narrow processing window.

Address:1821 Midpark Rd, Knoxville, TN 37921, USA

Superior Plastics

Superior Plastics: Providing Custom Plastic Molds Since 1981

We’ve really gotten to know the area well, too. We’ve been at the same location, here in the heart of the D/FW metroplex, since 1985. We’ve worked since that beginning on building our business around a few sound principals.

On Time Delivery

Our delivery is always on time. We work hard up front to make sure there is plenty of time to get your order to you when you need it. We also provide drop shipping & private labeled products. For more information contact us online or give us a call at 817-882-9595.

Quality Plastic Products at a Competitive Price

We have competitive prices. Other companies tend to charge more for a product of our quality, and that quality is outstanding. We love what we do, and we put a great amount of effort into bringing you a great product. Not just to please you, but because we enjoy it too. Many places have a strong product, but they’re not always easy to talk to. We pride ourselves on our excellent customer service. Our top priority is to create a long lasting relationship with our clients, and we understand that one of the best ways to do that is to communicate, offer competitive pricing and a quality product.

We promise you’ll enjoy your plastic mold as much as we enjoy making it. You’ll also have a great experience working with our team. You can depend on us to bring you what you need, when you need it.

Address:2412 Chester St, Fort Worth, TX 76103, USA

Conclusion

How to choose right injection molding services company is very important, Without looking further, we’re also injection molding services company in China. Rocheindustry aim to give purposeful reviews and information that is bound to save your time. In case of any questions, inquiries, or even comments, reach out to us.

If you’re looking for injection molding services with competitive price in China please contact us as below button.

Related source: Handbook: The Complete Guide To Injection Molding