Contents

What is Polycarbonate?

Polycarbonate is a thermoplastic compound that is known for high strength and impact resistance. It is usually used for tough engineering applications as it can sustain any external forces without breaking off or corroding.

This thermoplastic material is also capable of withstanding high temperatures. With a glass transition temperature of up to 150° Celsius, the material will still manage to maintain its physical and structural integrity.

In addition to heat resistant polycarbonate is a flame retardant material. Also, we cannot ignore the fact that this material is an electrical insulator.

Even with all these desirable features, polycarbonate still manages to carry minimum weight. It is lighter than most of the alternative materials that can be subjected to 3D printing.

How Strong the Polycarbonate as a 3D Printing Material

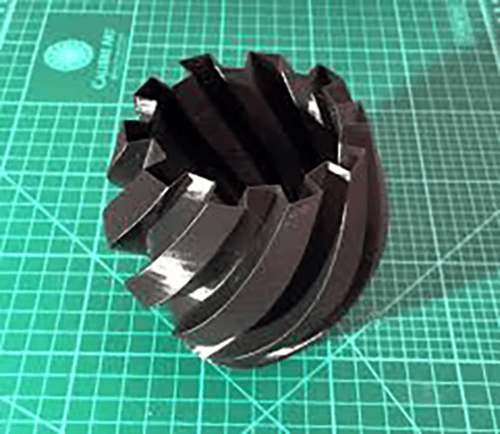

As we have mentioned, one of the key properties of polycarbonate is its strength. In fact, polycarbonate is usually referred to as the “King” of 3D printing.

This is because it is the strongest material that can be manufactured through 3D printing.

But, how strong is this material as compared to others? The strength of polycarbonate can be better understood when we look at the numbers.

A test that was conducted by the airwolf3d.com ranked different 3Dmaterials according to their hardness. The main materials that were subjected to the test include PLA, ABS, Nylon, and polycarbonate.

Each material was loaded with some weight which was attached to a hook.

Guess which material won? Polycarbonate won by quite a big margin.

With a tensile strength of 7250 PSI, PLA material managed to lift a weight of up to 285 pounds. ABS which has a tensile strength of 4700 snapped when hooked to the same weight.

Polycarbonate which has a tensile strength of 9800 PSI managed to lift the weight of up to 680 pounds without snapping. No other material could lift such weight.

I hope that now you understand why polycarbonate is the “King” of 3D printing.

What are the Uses of Polycarbonate?

The toughness, heat resistance, and durability make polycarbonate an ideal material for a wide range of applications. Some of the uses of polycarbonate include:

-Automotive industry for making parts of vehicles

-In the construction of buildings and transport infrastructure

-For constructing electrical and telecommunication hardware/ appliances

-For making digital data storage devices such as Blu-Ray Discs, CDs DVDs

-For making consumer products such as bottles, food containers, cases among others.

How Can I 3D Print with Polycarbonate?

With its hardness, how is it possible to 3D print the polycarbonate material? There is no doubt that polycarbonate can give you some headaches when it comes to printing it into other relevant products.

However, with the right people and the best 3D printer, the process can be easily executed without any fuss. Of course, you have to follow the right procedure when printing polycarbonate material.

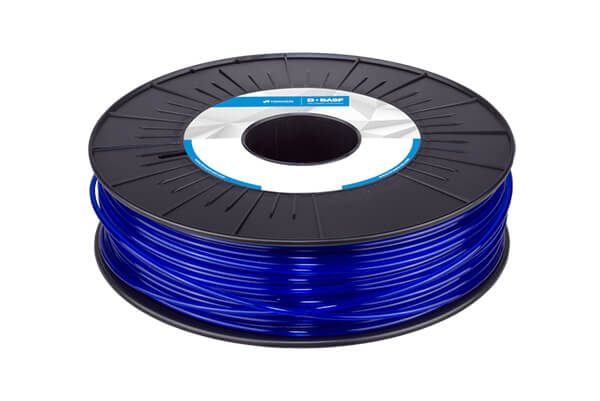

1. Choose quality polycarbonate filament

Like other materials for 3D printing, it always starts with making the right choice of the material. This is because low-quality filaments can result in low-quality prints.

You should beware of cheap polycarbonate filaments. Although they may appear to be flawless, they can cause some serious problems when they are 3D-printed.

Some manufacturers of polycarbonate tend to produce filaments that have fillers and additives. Such additions will affect the 3D printing process and even degrade the quality of the final products.

Inferior polycarbonate has air pockets that can end up jamming or clogging the 3D printer.

Do not be enticed by the low prices. Instead, take your time to carefully scrutinize the material for 3D printing.

Polycarbonate filaments that have inconsistent diameters can end up forming blobs, extrusions, and other imperfections when they are finally printed.

So, how can I find high-quality polycarbonate 3D filament?

The surest way is to buy from a trusted polycarbonate manufacturer. This way, you can be sure of the quality of the 3D materials that you will get.

You should also take your time to inquire from the manufacturer about the filament before you buy it. Ask them whether their polycarbonate contains any additives or other chemical elements.

If the situation allows, take some samples of the filament so that you can assess their quality.

After all, your ultimate goal of polycarbonate3D printing is to retain structural integrity and the beauty of the material.

2. Choose the Right Polycarbonate 3D Printer

After you have chosen a quality polycarbonate filament for 3D printing, the next step is to find the right 3D printer.

Given the physical, chemical, and structural properties of polycarbonate, you cannot just use any 3D printer to do the job. The printer should have certain attributes that make it suitable for the polycarbonate 3D printing.

For example, the printer should be capable of handling very high temperatures. It should also have an enclosed chamber where the polycarbonate material will be heated.

For years, having the right printer has always been a major impediment to 3D printing. This is because most 3D printers cannot sustain the extremely high temperatures that are required for printing polycarbonate filaments.

The highest temperature threshold of a successful polycarbonate printing is between 290°C and 320°C.

This automatically means that the few printers that can be used for printing this material are expensive. In fact, you will rarely find any that is below $50,000.

The good news is you don’t have to incur all these expenses. You can easily outsource the service to a polycarbonate 3D company and they will do the job for you.

For example, at Roche Industry has the right printer for 3D printing. Yours is to submit the filament and we well do the printing for you.

3. Enclosed chamber for 3D printing

Again, having the right printer for the process is not enough.3D printing for the polycarbonate should be carried out in an enclosed chamber.

The purpose of the chamber s to ensure proper temperature management so that the end product is devoid of any imperfections.

Thermal management prevents flaws such as cracks and deformations on the product.

4. Effective bed adhesion

Apart from proper heat management, polycarbonate 3D printing also requires a proper bed adhesion. This is the most challenging part when it comes to printing premium materials such as polycarbonate.

The fact that polycarbonate has a tendency to warp when processed leaves you with no other option but to pay attention to the adhesive property of the bed.

At Roche Industry, we ensure that all these four core aspects of polycarbonate 3D printing are given the full attention that they deserve.

What are the Limitations of Polycarbonate 3D Printing?

Although 3D printing is the best method of manufacturing objects that are made of polycarbonate, it also has some limitations.

Here are some of the disadvantages of this method:

-Printing polycarbonate material requires extremely high temperatures as compared to other materials.

-Polycarbonate material is prone to warping. This means all the conditions for the printing should be perfect otherwise warping will be inevitable

-There is a high likelihood of liquid polycarbonate to ooze during the printing process.

-Polycarbonate is a hygroscopic material. It is likely to absorb some moisture during the printing process. This can lead to 3D print defects.

How can I eliminate these limitations?

The best solution is to seek the services of the best polycarbonate 3D printing company in China. They have the right tools, conditions to produce the best results.

Reliable polycarbonate 3D service companies also have experts who handle the whole process with utmost precision.

Can Ender 3 Print Polycarbonate?

For people who can’t afford 3D printers for polycarbonate, they usually opt to use Ender 3 is a device that is usually used for 3D printing

Although it can still be used for 3D printing, you must apply extra stringent measures in order to get the best results from it.

For polycarbonate, it can be more complex due to the nature of this material. For instance, achieving very high temperatures with Ender is not a walk in the park.

Due to some deficiencies, the final product may end up having numerous defects. So, it is safe to say that you should not fully rely on Ender 3 for polycarbonate 3D printing.

Should I get Polycarbonate 3D Printing Service in China?

If you want to make parts and products using polycarbonate material. This leaves you with no option but to 3D print this material.

Should you pay for the polycarbonate 3D printing service or should you do the job yourself?

As we have seen, printing polycarbonate material is a technical and complex process. It is also very expensive to do this task.

It is also a risky affair as you may end up doing the process wrongly hence wasting the material.

The best bet is to outsource the service to reliable polycarbonate printing companies in China.

You will save some good amount of money especially if you get affordable polycarbonate 3D printing service.

Conclusion

As we have seen, you can get anything out of polycarbonate material. All that you need is an elaborate polycarbonate 3D printing service.

In case you need this service, we are there to help you. At Roche Industry, we specialize in providing accurate polycarbonate 3D printing service in China. Contact us for a free quotation.

Related source links:

Handbook: Everything you need to know about PETG

PETG vs ABS: What are the Differences?

PETG vs PLA: What are the Differences?

Polycarbonate vs Acrylic: What are the Differences?

Nylon vs Polyester: What are the Differences?

Trivex vs polycarbonate: What are the Differences?

White paper: The Complete Guide To thermoforming

Everything You Need to Know about PVC Pipe Sizes

Rocheindustry specializes in high quality rapid prototyping, rapid low-volume manufacturing and high-volume production. The services of rapid prototype we providing are professional Engineering, CNC Machining including CNC Milling and Turning, Sheet Metal Fabrication or Sheet Metal Prototyping, Die casting, metal stamping, Vacuum Casting, 3D printing, SLA, Plastic and Aluminum Extrusion Prototyping, Rapid Tooling, Rapid Injection Moulding, Surface Treatment finish services and other rapid prototyping China services please contact us now.