Contents

What are the Differences between Polycarbonate vs Acrylic?

For a more dialed comparison between acrylic and polycarbonate, it would be essential to look at the individual criterion relevant to users’ needs. Below are some fundamental aspects that can be used to compare acrylic and polycarbonate for a project. Hopefully, it will help you make sound decisions.

Strength

Both acrylic and polycarbonate weigh approximately half the weight of standard glass, but they are much stronger than glass and provide more resistance to impacts. Polycarbonate is more robust than acrylic. Compared to glass, the strength of acrylic offers 10 times more resistance to impact than glass. On the other hand, polycarbonate can resist impacting up to 250 times as much as glass.

Acrylic is more rigid than polycarbonate, which can be made in various flexible levels. Accordingly, acrylic cracks easily compared to polycarbonate when the two are placed under the same level of stress.

Clarity level

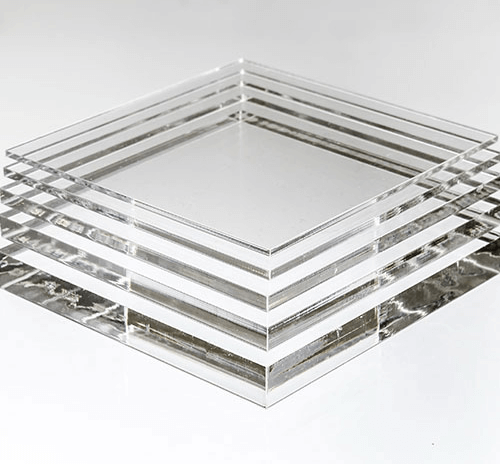

Acrylic is more transparent and offers better clarity than glass with a light transmittance of 92% compared to 88% of polycarbonate. Both plastics can be used for glazing, mainly secondary glazing. For instance, polycarbonate is mostly used in bus shelter glazing due to its strength.

Accordingly, acrylic can be easily polished to restore its clarity while polycarbonate cannot.

Working conditions (temperature resistance)

Acrylic can be comfortably used at temperatures that range between -30 degrees Fahrenheit and 190 degrees Fahrenheit. Acrylic expands and contracts accordingly if the temperature goes beyond the range provided above. However, it does not shrink permanently due to temperature changes.

On the other hand, polycarbonate can tolerate temperatures of up to 240 degrees Fahrenheit. Additionally, polycarbonate is resistant to both acids and petrol.

The ease of cutting

Both polycarbonate and acrylic can be cut using equipment such as routers and saws. Under the same conditions, acrylic is more natural to cut compared to polycarbonate. Due to its strength, polycarbonate resists the initial bite of a saw or router.

The ease of drilling

Acrylic is the hardest to drill because it cracks easily, especially when drilled near the edges using drill bits that are not designed for plastic. On the other hand, polycarbonate does not break even if drilled near the edges using an ordinary drill bit.

Polishing

As noted earlier, acrylic can be polished to produce a highly shiny surface, while polycarbonate cannot be polished.

Flexibility

Acrylic is stiffer and can only be bent using heat bending. On the other hand, polycarbonate is more flexible and can be bent more comfortably without using heat.

Maintenance (cleaning)

Both acrylic and polycarbonate can be cleaned more naturally and comfortably using a microfiber or a piece of cloth made from 10% cotton. Cleaning acrylic requires warm soapy water or an acrylic cleaner. Polycarbonate is more resistant to chemicals and can, therefore, be cleaned by harsher cleaners containing chemical compounds like ammonia. However, both acrylic and polycarbonate should not be cleaned using solvents.

Durability

Both acrylic and polycarbonate are tolerant of all conditions of weather and do not undergo any permanent shrinkage with changes in temperature. Both materials can be scratch (but not easily) and should not, therefore, be touched using abrasive materials.

Acrylic is most likely to succumb to impact and chip faster than polycarbonate. However, acrylic does not yellow over extended periods. Additionally, both materials are not easy to scratch.

Polycarbonate has the lowest flammability of the two materials. On the other hand, acrylic can burn slowly and is therefore recommended to keep it away from direct flames.

Affordability

Acrylic is more affordable compared to polycarbonate. Polycarbonate will likely cost 35% more than acrylic.

Lastly, both acrylic and can be glued using particular types of cement. However, acrylic provides a cleaner glue joint compared to polycarbonate.

Acrylic and carbonates pros and cons

Another way of differentiating acrylic from polycarbonate is by looking at their pros and cons. In this aspect, not only should you look at the characteristics but also the applicability of each material.

Acrylic Pros

- Easier to machine compared to polycarbonate

- Effortlessly polished to remove scratches and to give it cleaner and shinier edges

- Bonds well with glue

- Shinier and clearer

- More affordable (costs 35% less than polycarbonate)

Acrylic cons

- Stiffer and more rigid

- Chips easily

- More likely to crack when drilled

- Burns easily and should not, therefore, be exposed to open flames.

Polycarbonate pros

- More robust compared to acrylic

- More flexible and can be shaped more comfortably at room temperature

- Is non-flammable and can, therefore, be exposed to high temperatures without the risk of burning

- Highly resistant to most chemical compounds

- Can be drilled more comfortably without cracking

- More lightweight compared to acrylic

Polycarbonate cons

- Easily susceptible to scratches

- Cannot be polished to achieve shinier surface

- Easy to dent

- Less clear compared to acrylic

How to choose between acrylic and polycarbonate

Comparing acrylic and polycarbonate is the safest way of determining the one to use for a project. The comparison gives a clear idea of the right one to apply for a specific task. However, the selection of either acrylic or polycarbonate depends more significantly on the application.

To help you determine the right plastic to use between acrylic and polycarbonate, here are some suitable applications for each material.

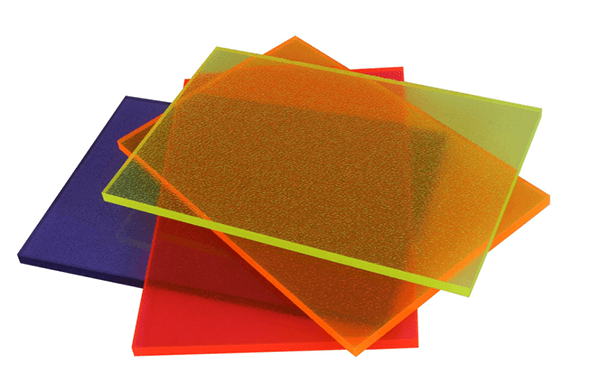

Acrylic Plastic Applications

- Alternative for glass windows

- Insulations

- Projects involving crafting

- Display units in retail stores

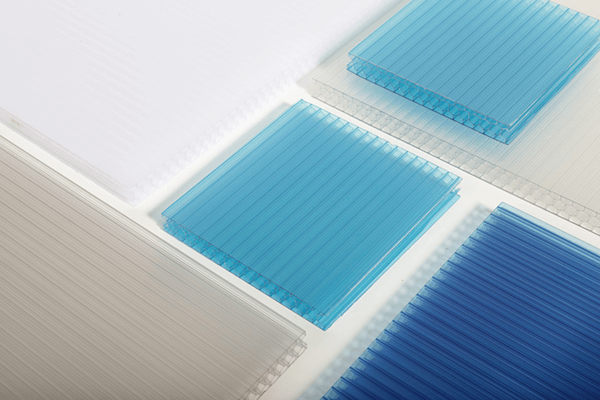

Polycarbonate Plastic Applications

- Bullet-proof windows

- Windows in greenhouses

- Roofing panels

- High-temperature model applications

- Clear casting molds

The bottom line

Acrylic and polycarbonate are commonly used plastic replacements for glass due to their strength and wide range of applications. The difference between the two forms of plastic lies in their physical and chemical characteristics and their applicability. Choosing the one to use for a project should, therefore, be a more straightforward decision based on the user’s needs for the material.

Related source links:

Handbook: Everything you need to know about PETG

PETG vs ABS: What are the Differences?

PETG vs PLA: What are the Differences?

Nylon vs Polyester: What are the Differences?

Trivex vs polycarbonate: What are the Differences?

White paper: The Complete Guide To thermoforming

Everything You Need to Know about PVC Pipe Sizes

Rocheindustry specializes in high quality rapid prototyping, rapid low-volume manufacturing and high-volume production. The services of rapid prototype we providing are professional Engineering, CNC Machining including CNC Milling and Turning, Sheet Metal Fabrication or Sheet Metal Prototyping, Die casting, metal stamping, Vacuum Casting, 3D printing, SLA, Plastic and Aluminum Extrusion Prototyping, Rapid Tooling, Rapid Injection Moulding, Surface Treatment finish services and other rapid prototyping China services please contact us now.