Stainless steel wire mesh is a crucial component in various industries. There is virtually nowhere you can go without finding stainless steel wire mesh used. This is quite simply because of the many benefits that stainless steel mesh commands. But, how does this metal have such a wide variety of applications? Here is everything you need to know about stainless steel mess that will help you have better insight.

In most cases, the primary function of stainless steel mesh is always to offer resistance to railings because it is not affected by corrosion and temperature changes. With this in mind, stainless steel mesh is commonly used in some of these industries:

- Chemical industry

- Pharmaceutical industry

- The mining sector

- Food industry

These are just but a few areas where stainless steel mesh is widely used. We will explore other areas as we proceed with this article.

Contents

Things you should know about stainless steel mesh

The first thing you should know about stainless steel mesh is that it is primarily backed by two grades, which are the T-304 and T-316 stainless steel. These two are also known as the standard and premium grades.

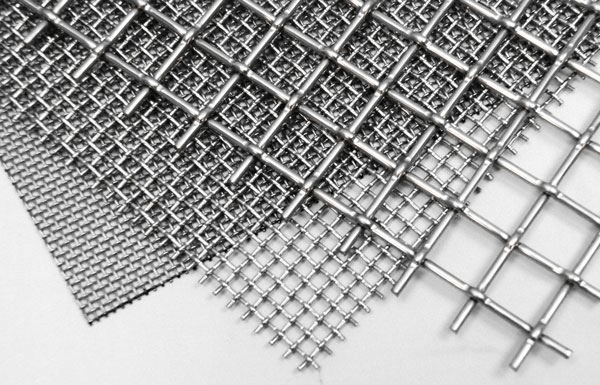

The stainless steel mesh comes in three different types, which are fine, medium, and coarse. Most manufacturers use stainless steel as their most preferred woven screen to make different products. And, that makes the selection of stainless steel mesh a bit complex because there are many grades in the market. However, you can always access some of the best variants form leading dealers, with the main ones being stainless steel mesh and stainless welded mesh. These two are the widely accepted variants and are majorly used for the following:

- Marine applications

- Filtration equipment

- Sizing applications

- Faucet Screen

- Insect Screen

- CRT Screen

- Light fixture

- Supporting filter media

- Decorative purposes

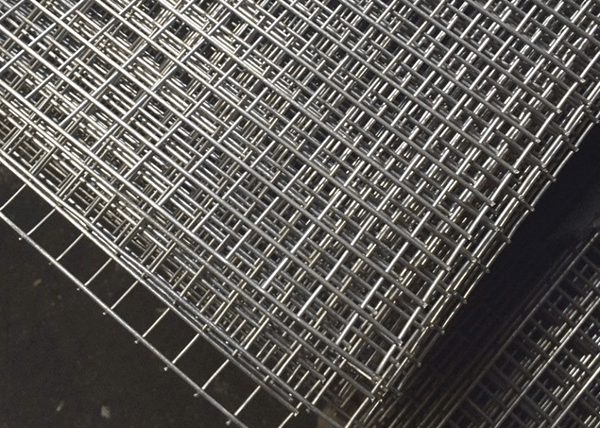

Stainless steel welded mesh

Stainless steel welded mesh is a widely used item because of its versatility and mechanical features. High-quality stainless steel mesh comes in two grades, which are T-304 and T-316. Stainless steel mesh takes the qualities of stainless steel, which explains why it is suitable or various applications. The mesh is highly resistant to corrosion and is always uniform in appearance.

Why you should choose stainless steel welded mesh

Apart from corrosion resistance, stainless steel welded mesh has impressive features that make it ideal for various uses. The wire comes with a clean look that leaves structures with a beautiful appearance. Additionally, stainless steel welded wire mesh is physically welded at every intersection, leaving the mesh rigid and intact, which makes it more durable. The strength and consistency developed by welding stainless steel to make stainless steel welded mesh make it suitable for general industrial applications. What is more impressive, the welded mesh can be reduced into smaller sizes and shapes without fraying.

Like any other mesh or wire cloth, stainless steel welded mesh is widely used in architectural projects, agricultural industry, commercial, and industrial applications. Stainless steel welded mesh is more resistant to heat, acid, and corrosion, and therefore lends these features to support railings. The high resistivity also makes it suitable for mining projects, food, chemical industries, and the pharmaceutical sector.

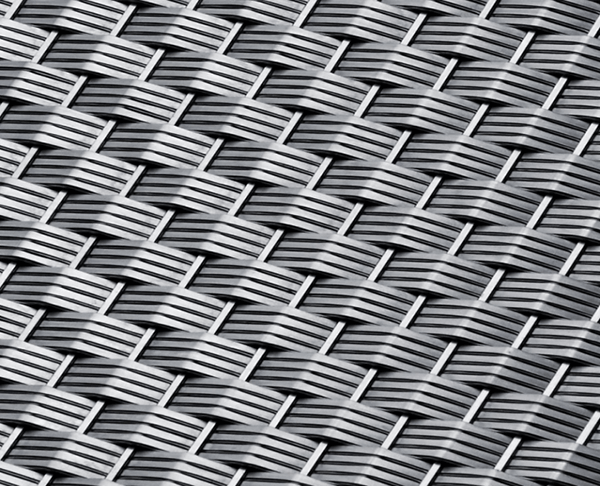

Stainless steel wire mesh

Stainless steel wire mesh contains chromium and nickel, which add corrosion resistivity and strength. In the annealed form, stainless steel mesh is non-magnetic. After weaving the stainless steel wire mesh, it becomes slightly magnetic because of the cold working.

Facts about stainless steel wire mesh

If you are not familiar with stainless steel wire mesh, it is one of the metal screens that are made by intersecting columns and rows of stainless steel uniformly. What makes it different from stainless steel welded mesh is the process used in manufacturing it. Stainless steel wire mesh is woven, while stainless steel welded mesh is welded as the name suggests. Both types are widely used in both home and commercial applications. Below are some of the things you should know about stainless steel wire mesh (woven or joined).

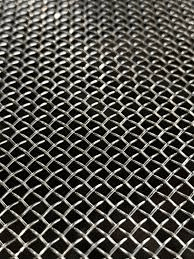

Stainless steel wire mesh comes in a variety of forms

One of the most astonishing specifications of stainless steel wire mesh is its different sizes and shapes. Additionally, stainless steel wire mesh comes with various alloys and materials. This feature makes it a versatile item that most people prefer. You can always find the right specification in size and shape you want for your projects.

Stainless steel wire mesh has unique weaves

Different manufacturers make stainless steel wire mesh with intricate columns and parallel rows. The materials, which are pieces of stainless steel metal, are woven at intersections to create unique designs that enhance their appearance and improve their compactness and strength. When the stainless steel mesh has been drawn into the desired shapes and sizes, it is fed into a machine that joins it at intersections.

Stainless steel wire mesh has a wide variety of applications

One of the most known facts about stainless steel wire mesh is that it is versatile and has multiple applications. The most common uses include shelving, fencing, and creating room dividers. Additionally, it used in ceilings, plumbing, and reinforcing concrete. Some people also use it in windows.

Food grade stainless steel mesh

Stainless steel mesh is a trendy material choice for food handling applications. Food grade stainless steel mesh takes all the properties of stainless steel metal and is, therefore, a suitable item in the food industry. Due to its high resistance to heat, food-grade stainless steel mesh is used to make many cooking wares exposed to high temperatures. Additionally, the material has an oxide layer that protects it from rusting, which can contaminate food.

As with many materials, there are some things you need to know about food-grade stainless steel mesh before rushing to use it. Here are some:

The finishing in stainless steel mesh can affect how it used in food processing

Stainless steel is widely known to be resistant to corrosion and has a shiny surface. However, it is essential to understand that the clean and bright looking surface does not necessarily mean it is food-grade. The finish of the stainless steel mesh has to meet sanitary standards to be used in the food industry. This feature is enhanced by eliminating any surface elements that may result in bacteria and making it easy to clean and sanitize.

This effect is created by processes like electro-polishing instead of manual grinding or filing. This process removes the surface layer, leaving behind a microscopically smooth strip. When this is done, the oxide layer’s strength is enhanced, and microscopic flaws that harbor contaminants are removed.

Food-grade stainless steel mesh should not be cleaned using a plain steel brush

Steel wire brushes are commonly used to clean the metal surfaces to remove deep-set stains. However, this is not the case in any stainless steel object. Particles from plain steel brush are easily embedded on the surface of the stainless steel mesh and affect the oxide layer. If this is repeated over time, it makes stainless steel mesh prone to rusting.

Food-grade stainless steel meshes are created differently

You should always know that not all stainless steel meshes that are marketed as food-grade are made equally and are the right items for food processing. There are many alloys of stainless steel in the market, and all of these can be used to make stainless steel mesh. Each of the alloys has different features depending on the alloying elements used to make them.

For instance, 304 stainless steel is resistant to corrosion but can be affected by the salt if it is exposed over an extended period. This means that 304 stainless steel mesh is not suitable for making cookware that is exposed to salt or saltwater for long.

On the other hand, 316 stainless steel is more resistant to salty conditions and is, therefore, an ideal choice for cookware exposed to salt or saltwater.

Extreme temperatures affect food-grade stainless steel mesh

Most stainless steel meshes used in the food industry have melting points that are way outside the temperature ranges experienced in the industry. However, temperature extremes may affect any coating or surface of the food-grade stainless steel mesh. Most alloys become brittle at temperatures below -490F. However, this should be a significant concern because standard cooking applications do not reach such extreme temperatures.

Machine processes can alter the properties of the stainless steel mesh

Heat stress experienced during some machining processes such as welding can remove the protective oxide layer, exposing stainless steel mesh to rust and corrosion. Food-grade stainless steel mesh should not corrode, and when this happens, the safety of food is compromised.

Some machines are regulated to reduce such effects by minimizing filler materials and extreme temperatures during the manufacturing of stainless steel mesh.

The bottom line

Getting to know the pros and cons of stainless steel mesh before jumping to use it for your project is a critical step that ensures safety, sanitation, and efficiency. This is only possible if you know more about stainless steel mesh.

Related source links:

Everything You Should Know About Stainless Steel Grades

Everything You Should Know About Stainless Steel Sheet Metal

Everything You Should Know About Stainless Steel Finishes

Handbook: The Complete Guide To Steel Gauge Chart

Rocheindustry specializes in high quality rapid prototyping, rapid low-volume manufacturing and high-volume production. The services of rapid prototype we providing are professional Engineering, CNC Machining including CNC Milling and Turning, Sheet Metal Fabrication or Sheet Metal Prototyping, Die casting, metal stamping, Vacuum Casting, 3D printing, SLA, Plastic and Aluminum Extrusion Prototyping, Rapid Tooling, Rapid Injection Moulding, Surface Treatment finish services and other rapid prototyping China services please contact us now.