Many machine shops are developing parts with high accuracy to make the final piece more functional. For instance, if you manufacturer supplies for aerospace companies, he must feature a tolerance level 0f +/- 0.0005 inches. Such will prevent big flaws while constructing an aircraft.

If you fail to include tolerance, the material will fail, prompting the customer to look elsewhere. As a way of retaining customers, machine shops should use accurate techniques of shaping and cutting parts.

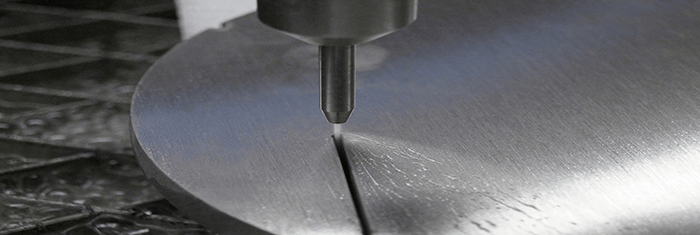

Water jets cutting is part of the processes that machine shops are looking to improve on accuracy.

Contents

CNC Water Jet

It is merely the equipment that utilizes the high-pressure water jets and eventually cut multiple metals. For it to cuts soft materials like rubber and wood, it uses water. Also, you can mix water with other compounds such as an Aluminum oxide or garnet when cutting harder materials.

The process happens underwater as a way of reducing slash or noise. The average water pressure should range between 20000 and 55000 PSI.

Pounds Per Square Inch is the full name that represents the acronym PSI.

Alternatively, your pressures can comfortably range between 50000 and 60000 PSI. One can use the pump to feed the CNC water jet with water. You must consider filtering since the process will require clean water. Pure water will provide optimal pressure, necessary to create a cutting stream.

Also, you need to filter this water as a way of protecting high-pressure parts. In extreme cases, you may need a water treatment plant in case the water features some toxic minerals. The danger of harboring compounds is that it may lead to premature corrosion. The same damage can reflect on the pressurized components.

Notably, if the water has minerals like chloride, magnesium salts, and more, it will reduce the level of pressure. In response, you will have to consider using a water softener. The water jet systems have specifications on particular sizes they can comfortably handle.

You can understand the suitability of your water source by checking the TDS of the water content. TDS is total dissolved solids. Some manufacturers use reserve osmosis whereby the TDS manifests in excess.

How Water Jet Cutting Works

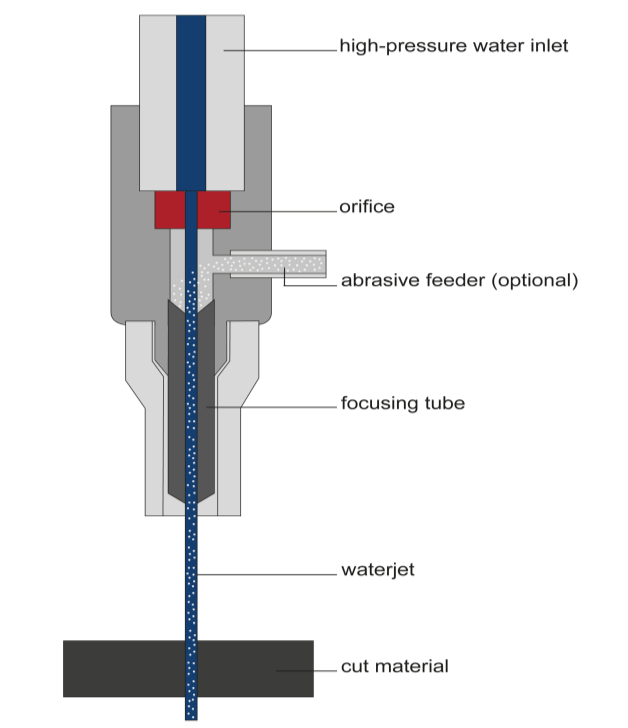

The CNC water jet is a tool that will accelerate the cutting or erosion. It works more than a mechanical sawing process in cutting the metal. You will use a nozzle to direct a high-pressure thin stream of water. On some occasions, it may include sharp rock pieces to hit the machine that is under the cut.

You will connect the high-pressure pump to the nozzle for a supply of steady pressure. The rock pieces are usually garnet. You can also use other materials instead of garnet.

Procedure

You will begin by generating pressures with the assistance of a high-pressure pump. The second action is converting this pressure into velocity through an orifice that has a smaller diameter.

Last, introduce the garnets, which are useful in magnifying the cutting ability by 1000 times.

Adding the Abrasives

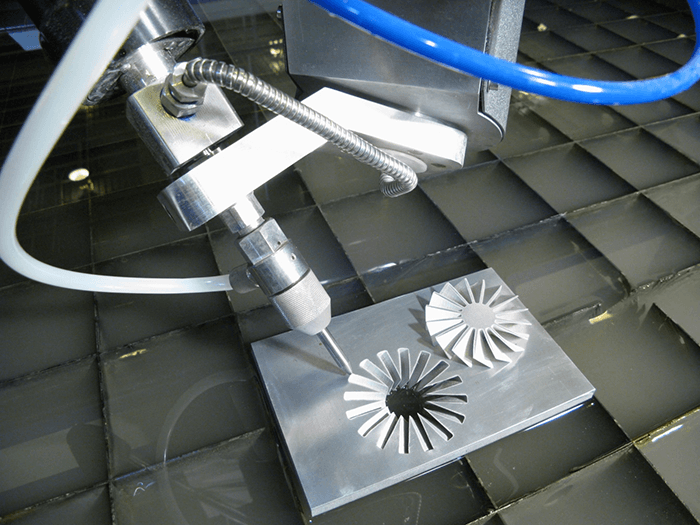

A CNC machine can operate with abrasives or additives. Some of them are garnet or aluminum oxide, which will enhance the cutting process. You can mix the abrasive into the water jet cutting head.

As you add the abrasive, it exits the focusing tube in a water stream, which will effectively wear through hard metals like steel. The same stream of water will quench any heating that results in the process.

Still, the momentum of the stream will ideally ensure that the particles travel on the straight line as they exit the nozzle. Such a design makes it be super straight and enhance the accurate cutting of various metals.

You need abrasive water jet cutting to cut hard materials that pure water cannot cut. Examples of these hard materials are metal, stone, and synthetic ceramics.

It is noteworthy that there are some materials which CNC water jet cannot cut at all. A perfect example is a tempered glass, which shatters whenever you attempt to cut.

Advantages of Using A CNC Water Jet Machine

The main benefit of using a CNC machine is that it cuts perfectly without interfering with the structure. You can cut your metal without changing the intrinsic properties of the materials. Some of these materials respond to heat, which is not the case with water jet machines.

Other benefits are as follows:

- Cuts heterogeneous metals

- Cuts complex shapes

- High precision cutting

- It cuts hard materials like hardened steel and stainless steel

- Heat free, odorless and dust-free

Disadvantages of A CNC Water Jets Cutting Machine

- It takes a more extended period to cut through as compared to other traditional methods

- The methods are costly when compared to other convectional DIY

- It is not a recommended method of cutting thick materials.

Water Jet Accuracy and Workpiece Thickness

If the workpiece is thicker, it comes harder for the water jet to cut through accurately. For instance, if the materials are more viscous than one inch, the cutting accuracy will automatically reduce. Precisely, it may decrease to 0.1 inches.

You have to drill a hole into the workpiece for the water jet to cut through accurately. The first hole done by this water jet cutter is typically irregular. Suppose the workpiece is thicker; the first hole will also be more irregular hence demanding extra work as you begin to cut.

As you begin to cut through, the cutting line will be incredibly accurate. The cool thing is that you can improve on the accuracy of cutting thicker metals. You can do so by pre-drilling pilot holes on the materials with Electrical discharging machine EDM.

Water jet Cutting and Tolerances

Heat is an aspect that one many forget while doing the precision cutting. Many consider laser since the method is ultra-precise and will also leave a smooth edge. Unfortunately, these lasers transfer a lot of heat into the materials as they cut.

Such heat may affect the properties of the workpiece. Such a loop may affect the quality of the end product. Instead, you need the water jet to do the same job since it does not transfer heat.

Choosing the right Water jet material

It will be wrong if you hastily buy any water jet machine. Avoid getting carried by discounts and consider certain elements that can make you acquire the right equipment. Let’s look close at some of these requirements:

Cutting Materials

There are two commonly available types of cutting materials. They may be either soft or hard materials. You need to add grit to the stream water for you to cut a harder material properly.

You will have to choose a proper model of the CNC water jet that can correctly handle harder materials.

On the other hand, you will only require pure water to cut soft materials. These materials are thinner plastics or wood. Also, the ideal machine uses less pressure as compared to the one that cuts steel metals.

The complication of the cut

Multiple jobs need a water jet machine. It’s vital for you to understand the complexity of some cutting situations. If the machine cuts highly complicated tasks, the water jet will require some new mechanism.

The new mechanism is synonymous with a fifth axis. It will help you to cut complicated angles more accurately. Another advantage with the fifth axis machines is that they excel in weld preparation work.

In case your cuts are mainly basic, then you can settle for an ordinary Water Jet machine. You need to do proper research so that you do not spend extra money on an expensive machine.

Consider purchasing a used machine

Sometimes the budget set might not allow you to buy a brand new device. With that in mind, it will be reasonable to locate a refurbished device that can do the same job. The market is full of such devices.

At this point, you need to follow the expert advice so that you do not land into a ditch. Alternatively, use some reputable sites that sell these machines at an affordable rate. Check all the parameters to establish that the device will not disappoint you soon.

Typically, water jet machines are costly. You can avoid killing your dream of owning one by looking for an alternative from the market.

Inspect it thoroughly before buying it.

Final Thoughts

We live in a tech-savvy society that is ever thirsting for more and better versions of technological developments. As a beneficiary of these new inventions, you will have to adapt to the new changes for you to be relevant.

In the meantime, the water jet cutting machines are increasingly taking over from other traditional methods. One will use them to cut some materials with a high level of accuracy precisely.

Moreover, they offer a decent tolerance level making their end product to gain popularity over other conventional methods.

Do you want to increase the confidence level of your clients in your product? Indeed, settle for the modern machine while cutting machine parts.

Accuracy and precision are what many shoppers are looking for, and it is reasonable to satisfy them.

Rocheindustry specializes in high quality rapid prototyping, rapid low-volume manufacturing and high-volume production. The services of rapid prototype we providing are professional Engineering, CNC Machining including CNC Milling and Turning, Sheet Metal Fabrication or Sheet Metal Prototyping, Die casting, metal stamping, Vacuum Casting, 3D printing, SLA, Plastic and Aluminum Extrusion Prototyping, Rapid Tooling, Rapid Injection Moulding, Surface Treatment finish services and other rapid prototyping China services please contact us now.