There is no doubt that aluminum sheet metal is a uniquely versatile metal sheet that has numerous applications in the modern world. Its physical, structural and chemical properties make it among the most popular metal sheets.

Are you planning to buy the best aluminum sheets? It is important that you read this article. I am going to reveal everything that you should know about aluminum sheet metal.

Contents

What is Aluminum Sheet Metal?

Simply defined, aluminum sheet metal is a product formed when aluminum material is pressed and rolled under intense pressure. Generally, the aluminum sheets are lightweight but strong enough to be used for a wide range of applications.

The extreme versatility of the aluminum plates is boosted by the ease of installation and maintenance. This explains why the aluminum sheet is among the most popular metal sheets.

Different types of coatings are applied to the aluminum sheet metal. The purpose of coatings is to increase the strength and durability of the aluminum sheets. They also make the sheet applicable to different conditions.

There are different surface finishes of the aluminum metal sheet. Some a/re smooth and uniformed while others are rough or rugged. The choice of the aluminum plate texture will depend on its application areas.

Aluminum sheet metal comes in different sizes. You are free to choose the size that will perfectly fit your application. All you need is to communicate with the aluminum sheet metal manufacturer and specify the size. As expected, the price will depend on the size of the aluminum metal plate.

Types of Aluminum Sheet Metal

Aluminum sheet metals are not all the same. They come in different forms. Here are the types of aluminum sheet metals that you will find in the market.

1. Perforated aluminum sheets

Also known as the plate aluminum, it is oftenly used in applications where there is a need to add aesthetic value. They are known for their good looks. Such applications include interior/exterior design, construction of ceilings, sun shades, screens among other decorative panels for building, construction and architecture.

This type of aluminum sheet is also used in food, pharmaceutical, and laboratory industries.

2. Chequered aluminum sheets

As the name suggests, this type of aluminum sheet is characterized by numerous raised hatch marks on one side and the other side remains untextured marks. Some people call these aluminum sheets to tread plates durbar floor plates and bar sheets.

These aluminum sheets are sturdy and can withstand high-impact force. They are perfectly suited for both interior and exterior applications. Because of their strength and sturdiness, you can use them for heavy-duty applications. These include loading bays, car parks, flooring systems service corridors among others.

3. Brushed aluminum sheets

Almost all the aluminum sheet metal exists in two forms. They are either brushed or unbrushed. In this context, we are using brushed to mean that the metal sheet ha a fairly uniform pattern. Alternatively, some have light scratches and scuffs that are uniform and parallel to each other.

This type of aluminum sheet metal is also ideal for creating aesthetic effects. They are stylish and well-polished. You can use them to accentuate your interior design ideas. They are applicable to both domestic and industrial applications.

4. Composite aluminum sheet

This type of aluminum sheet is usually abbreviated as ACS. It comprises pieces of coil-coated aluminum that are bonded to the non-aluminum core which in most cases in plastic. They are among the lightest aluminum sheets metal in the market.

Composite aluminum sheets are also robust since they carry minimal weight. This feature makes them an ideal choice for external cladding. Because of this, they are sometimes known as dibond sheets or sandwich panels.

Their lightweight also makes it easy to install and maintain. They can be easily cut and shaped for different applications. Some of their applications include cladding and decorations

5. Anodised Aluminium Sheets

In chemistry anodising is a process of introducing a layer of oxygen onto the metal sheet hence increasing its thickness. This means that anodised aluminum sheets have an oxygen layer. The goal of this layer is to increase the resistance of the metal from the effects of wear and tear. It can also be used for increasing the adhesiveness of the metal, especially hen you want to attach other chemicals such as glue and paints onto it.

Anodised aluminum sheet metals are commonly used for decorations. This is because they tend to create strong bonds with other materials.

So, which type of aluminum sheet metal will perfectly work for your application? Once you identify it, go ahead and make the purchase. If not sure, then consult experts from the best aluminum sheet metal manufacturers.

Key Properties of Aluminum Sheet Metals/ Advantages

Before buying aluminum sheet metal, you should know the key elements that characterize this metal. Here are some of the most noticeable benefits of aluminum sheet metal that you should know:

-Lightweight: The Aluminum sheet is among the lightest metal sheets in the market. In terms of comparison, it is 1/3 the weight of a steel sheet. This property comes with numerous advantages. You can handle the metal sheet with total ease.

-Strong: Despite being lightweight, aluminum sheet metal is quite strong. Its strength makes it usable for industrial applications. This advantage of the aluminum metal sheet also makes them durable and cost-effective

-Resistant to corrosion: Can aluminum metal sheet corrode? This is a question that you may ask yourself. Aluminum is among the metals types that don’t corrode so easily. It will only corrode if subjected to extremely aggressive conditions.

-Easily formable: Aluminum sheet metal has a relatively low melting point. This means that it can be easily formed into different shapes when subjected to a certain level of heat.

-Suitable for sensitive applications: Aluminum sheet metal can be used for sensitive applications such as chemicals and food packaging. They are used because they don’t react easily with other materials.

You won’t have to worry about the flavor of the food being affected by the aluminum sheet container.

-Fireproof: Will the aluminum sheet burn? Aluminum sheet metals don’t burn when exposed to flames of fire. Only a thin layer of the metal sheet will get affected. They also don’t release toxic gas when exposed to heat.

-Has reflective properties: An aluminum sheet metal can reflect the light and even heat away from its surface. This property makes it an ideal choice for lighting applications.

-Recyclable: The most popular advantage of aluminum metal sheets is the ability to be recycled. Most aluminum metals that are in use today are a product of recycling.

– Available in different thickness: The flexibility of the aluminum metal sheet makes the available in various dimensions. You can choose different size and thickness of the metal sheet.

Aluminum Sheet Metal Gauge

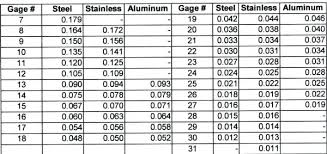

When buying and working with aluminum sheet metal, it is normal for the expression “gauge” to be used. If you are new to the gauge framework may not comprehend what is implied by 18 gauge steel, for instance.

So, what is aluminum sheet metal gauge? Gauges, in most cases, are used for expressing the thickness of aluminum sheet metal. The metal sheet gauge does not have defined standards or metrics.

When using aluminum sheet metal gauge, you will need a conversion sheet to determine the actual thickness of the aluminum metal. This can be measured in terms of millimeters or inches.

For example, an 18 gauge aluminum sheet metal has a thickness of 0.0408 inches according to the metal gauge. Take note that the gauge of a particular metal sheet may not be the same as the one of another metal sheet.

Image of aluminum sheet metal gauge chart source http://caresi.rezon.co/aluminum-thickness-chart/

Aluminum Sheet Metal Uses

Aluminum sheets have found their usefulness in different areas You can without much of a stretch see aluminum sheets being utilized on vehicles for its bodies and for framing. You can likewise observe aluminum sheets used for packaging in the food and beverage industry, and as parts of cookware and apparatuses.

Sheets of aluminum can likewise be seen being utilized by the construction and building industry through the material, drains, sidings and such.

Aluminum sheets are likewise perfect for use with the making of metal nameplates and other comparative things. Number plates for vehicles are regularly made of aluminum sheets for the most part in light of the fact that they are lightweight and come at reasonable costs. These are likewise utilized because of their corrosion resistance and require fairly minimal maintenance.

The uses of aluminum sheets will in most cases depend on its thickness. Thinner aluminum sheets being utilized for small scale applications. It is at this point that the importance of aluminum sheet metal gauge comes in. You can use it to know the thickness of the sheet and know whether it will fit into your application.

The good news is there is always a way out when you are not so sure about the thickness of the aluminum sheet. Just consult the best aluminum sheet manufacturer near you.

How to Choose the Best Aluminum Sheet Manufacturer/Supplier

If you are in constant need of an aluminum sheet, then you should focus on buying from the best manufacturer, supplier or distributor. This is the surest way of getting the best aluminum sheet.

By buying from a reliable aluminum sheet manufacturer, you can be sure of the quality. The best manufacturers follow all the required standards to ensure that their aluminum sheets meet the global standards. As a buyer, you will definitely enjoy the ultimate benefits that come with using a quality sheet.

But, how can I get such a manufacturer or supplier for the aluminum sheet metal? Just use the following tips:

Choose experts in Aluminum sheets metal

One of the most significant characteristics that an aluminum sheets supplier ought to have is extraordinary information aluminum. There are numerous organizations that will store and ship this metal sheet, however, don’t have any information about the metal, its properties, its combination, its uses, and its restrictions.

A specialist in aluminum metal supplier will think about how delicate the metal is, the significance of putting away it dry and away from dampness, how it can get handily harmed when moved with heavier metals, etc.

Consequently, when one is picking the metal sheet manufacturer, it is critical to pick one that knows everything about the aluminum sheet.

The price of aluminum sheet metal

Reasonable valuing is a factor you ought to think about when in the market for a solid aluminum sheet metal supplier or manufacturer. Sensible rates are constantly an or more, particularly in case you’re hoping to purchase many aluminum sheets wholesale.

Some manufacturers and suppliers offer cheap aluminum sheets that are of low quality. So, your decision should not just be on the price. Instead, the price should be related to the quality of the aluminum sheet.

Along these lines, you’ll have the room on your spending limit to purchase a reasonable number of the items you require. A good supplier will offer you some amazing aluminum sheet discounts.

Roche Industry- The Best Aluminum Sheets Metal Manufacturer

You will also enjoy competitive pricing when you buy from a reputable aluminum sheet supplier. A reputable iron sheet supplier won’t try to overcharge you. You will pay the actual value for the sheet.

At Roche Industry, we have immense experience in designing and manufacturing aluminum sheets for sale. We have been doing this business for many years and our reputation in this field is unrivaled.

Would you like to know the price of aluminum sheets? Simply contact us and we will send a free quotation. We will do all that it takes to ensure that your needs with regards to the aluminum sheets are fully satisfied.

Rocheindustry specializes in high quality rapid prototyping, rapid low-volume manufacturing and high-volume production. The services of rapid prototype we providing are professional Engineering, CNC Machining including CNC Milling and Turning, Sheet Metal Fabrication or Sheet Metal Prototyping, Die casting, metal stamping, Vacuum Casting, 3D printing, SLA, Plastic and Aluminum Extrusion Prototyping, Rapid Tooling, Rapid Injection Moulding, Surface Treatment finish services and other rapid prototyping China services please contact us now.

Related source links:

White Paper: The Complete Guide To Sheet Metal Fabrication

Essential Design Tips You Should Know About Welding Sheet Metal