Contents

What is Mold Making?

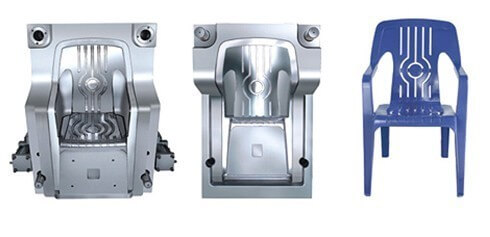

Mold making or molding is the process of manufacturing by using fluid or flexible crude material utilizing a strong and rigid material called a mold or matrix. This itself may have been made by using the model of an already existing product.

A mold or mold is a hollowed-out block that is filled with a liquid or pliable material such as plastic, glass, metal, or ceramic raw material. The liquid hardens or solidifies, adopting its shape.

Mold is similar to a cast object. Both have a bi-valve molding process uses two molds, one for each half of the object.

Articulated molds have multiple pieces that come together to form the complete mold, and then disassemble to release the finished molding product. Even though they are expensive, they are vital when it comes to shaping complex overhangs.

Mold making uses a number of different molds, each creating a section of a complicated object.

This is generally only used for larger and more valuable objects.

What is the difference between molding and casting?

Mold making and casting are two terms that are closely related. In fact, there are many instances where these two words have been used interchangeably. Both of them are used in the 3D printing for creating solid objects. Is casting the same as molding? If not, what are the differences between mold making and casting?

Molding or Mold making is an elaborate process of making the cavity/structure that conveys a negative or opposite impression of an original model. Molds can be made of an inflexible or rigid material, for example, mortar or plastic resin or all the more generally, an adaptable material, for example, rubber.

The material to use for molding is determined by the nature of the item that you are planning to mold. Will the two create a perfect fit?

Casting, on the other hand, entails pouring molten material into the cavity of a mold. After a specific timeframe, this fluid will solidify response or cooling. The solidified part is otherwise called a casting, which is launched out or broken out of the mold to finish the procedure.

Casting materials are normally metals or different setting materials that form themselves after mixing different agents. In most cases, it is epoxy, plaster, and clay.

The table below gives a clear difference between molding and casting manufacturing methods.

| Molding | Casting |

| Usually used ion soft materials such as polyester and soft metals like aluminum | Made of common materials such as gypsum and resin |

| Made through a molding process | Made through a casting process |

| Molding is done before the cast | A cast is done after the molding process |

Mold Making Materials

Is my material suitable for the mold making process? This is a common question that most manufacturers would when planning to have mold making services.

This form of manufacturing is quite versatile. This means that it is suitable for a wide range of materials.

Most of the mold making materials are made of artificial rubber or resin. This material is ideal for mold making because it can be easily reproduced into different shapes.

You can get several details out of a simple rubber material. Some types of rubber that can be easily subjected to mold making include epoxy, polyurethane, and silicone.

However, mold making is capable of working on more rigid material such as gypsum. Cases of aluminum molding are also not rare.

Mold making does not have any negative impact on the materials processed. The chemical and physical properties of the molding materials will remain the same. What will change in the form of the material

Aesthetic properties of the material will also be retained after the process. You will still have your colorful parts and products.

Still not sure whether your material qualifies for the molding? Consider contacting mold making manufacturer for further advice.

At Roche Industry, we will not hesitate to give you appropriate advice.

Types of Mold making Techniques

As we have seen, mold making is used for manufacturing different types of materials.

Since each material is unique on its own, it is imperative that different techniques are used in molding them.

When you take your material for the molding services, these are some of the techniques that will be used to refine it.

1. Blanket Mold making

This is by a wide margin the most effortless kind of mold. It is frequently used to recreate plaques and models in which one side isn’t secured by mold material.

In this mold making process, the original object is fixed to a base as a rule with heated glue, and the molding material is poured over it and is given time to cure.

At the point when set, the mold is flipped over, and the first evacuated to uncover the blanket mold prepared for molding material.

This method usually results in thick mold products. It also eliminates the need for using paint or sealing when creating the molds.

One of the advantages of blanket molding is it minimizes wastage of the material. The whole process is also energy-saving.

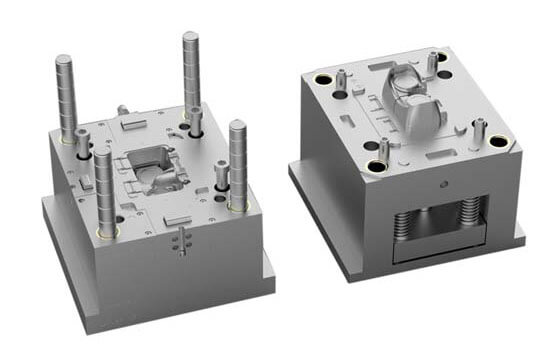

2. Block mold making method

In this mold making process, an original is affixed inside a mold box or container. The mold material is then filled and loaded up with around one inch higher than the top-most point of the original mold.

At the point when the mold is expelled from the box or its container, it looks like a square of mold material along these lines its name.

To eject the mold, the first a cut is made on each side of the elastic the going 66% down. The mold is spread open like a mollusk shell, and the original is ejected. An elastic band is used to keep the mold shut when the casting material is poured.

3. Injection Mold Making

This kind of mold is made thin-walled and needs support other than gravity to embed the molding material.

A two-section mold frequently forms the basis for an elastic injection mold. When the mold is finished, sprue holes are added to permit air and abundance molding material to getaway.

At that point, a large hypodermic needle (generally a pony hypodermic) is loaded up with the molding material and crushed into a hole inverse the sprues until the molding material starts to leave the sprues holes.

4. Two-part molding

This method is usually used for molding complex objects. Such objects tend to have sophisticated shapes and designs.

In the two-part molding, each side of the object is molded one after another.

5. Shell mold making

Most molds are two sections. The initial segment is the soft rubber, which takes the real impression of the first. This material is slim and adaptable, and whenever expelled from the first won’t keep its unique structure. So an additional rigid layer is included top of the rubber known as a shell or mother mold. Gypsum plaster and plaster wraps made an economic shell.

6. Transfer molding

This is an assembling procedure where the molding material is constrained into a mold. Move molding is not quite the same as pressure molding in that the mold is enclosed instead of open to the fill-up the plunger bringing about higher dimensional resistances and less environmental pollution.

7. Matrix molding

This is a strategy regularly used during molding. The individual doing the gathering will initially make the inflexible external shell, and then introduce the softer and progressively liquid molding material between the shell and the model. This procedure is regularly used for complex shapes using composites, such as glass and glass/ceramic composites.

Advantages of Molding Services

If you intend to manufacture parts and products, there is a high chance that mold making is one of the processes that you would like to undertake.

Here are some of the benefits of getting mold making services in China;

1. Fast production process

There are many reasons that molding is known as the most widely recognized and most proficient type of manufacturing. The process itself is incredibly quick contrasted with different methods, and the high creation yield rate makes it significantly increasingly productive and practical.

The speed of the molding relies upon the multifaceted nature and size of the mold, yet just around 15-120 seconds per cycle.

With the brief time frame between cycles, more volumes of molds can be created in a restricted measure of time, therefore expanding conceivable profits and overall revenues.

However, fast production will only come from the best mold, making companies. This is what we at the Roche industry do. We will ensure that you get your products on time.

2. Complex design molding

Mold making can handle extremely complex parts, and uniformity, as well as the ability to make millions of virtually identical parts.

No matter how complex the design is, the process will be able to maintain high levels of accuracy. All the dimensions will be maintained to the highest precision.

The part design must be developed to maximize the efficiency inherent in high-volume molding.

With the right design, parts can be made consistently and be of high quality. Without good design, costly processing mistakes can be made.

The sophisticated molding machines at Roche Industry are capable of coming up with any design that you want.

3. Maintains the strength of the material

The strength is one of the key factors that should be resolved when structuring a molded part.

The architect should know whether the part should be adaptable or rigid with the goal that he/she can change the incorporating components.

Mold making helps to maintain the physical strength of the parts that are molded. It ensures that physical strength is not depreciated.

Seeing how the client will use the part and what kind of condition the part will be exposed to is likewise significant.

Of course, the selection of the material will still have the ultimate impact.

4. Versatile: Different materials and colors

As we have seen, mold making can be used on a wide variety of materials. You can use it on a wide variety of resins, polymers, and even a couple of soft metals such an aluminum.

The materials may vary in terms of strength, size, and chemical properties.

So, whichever type of material that you would like to use for creating parts, be sure that it will be molded into anything you want.

Apart from the materials, mold making allows exploration of different colors and decorations. You can use many different colors to improve the aesthetic value of your molds.

5. Minimum wastage

Would you like to save on the usage of the materials for your parts? Molding can be a perfect method to help you achieve this goal. The method is properly refined to ensure that every bit of material is properly utilized.

Even as it reduces wastage, mold making also helps to preserve the environment. This is because the process ensures that the non-biodegradable material will not find their way to the environment.

6. Cost-saving molding

What is the cost of mold making services? You may ask. Although the cost of molding may vary depending on several factors such as material, one thing for sure is the process is cheap.

You will save a lot of money when you choose mold making as a form of manufacturing your parts.

As we have seen, the minimum wastage of the materials will have a direct impact on your finances. The same applies to the time-saving factor of molding.

Definitely, there are are many other advantages that can convince you to choose mold making services in China. You will be privileged to enjoy them only if you choose the correct molding company.

Mold Making Services in China: Roche Industry

Are you looking for the best mold making services in China? You are at the right place. We at Roche Industry have the solutions to all your molding needs.

Regardless of the molding material type that you would like to be molded or the design, we will strive to provide top-notch molding services. Our experience in this industry speaks for itself.

Rocheindustry specializes in high quality rapid prototyping, rapid low-volume manufacturing and high-volume production. The services of rapid prototype we providing are professional Engineering, CNC Machining including CNC Milling and Turning, Sheet Metal Fabrication or Sheet Metal Prototyping, Die casting, metal stamping, Vacuum Casting, 3D printing, SLA, Plastic and Aluminum Extrusion Prototyping, Rapid Tooling, Rapid Injection Moulding, Surface Treatment finish services and other rapid prototyping China services please contact us now.