Contents

Overview of Resin Casting

Casting is a typical manufacturing process that includes pouring fluid material — normally material that has been preheated — into a mold cavity.

As the fluid material cools, it solidifies to make another product looking like the mold.

The recently made product, known as a casting, is then ejected from the mold and either utilized for other manufacturing forms or bundled and sold as a final product.

Resin casting, in any case, is a remarkable casting process that is portrayed by the utilization of manufactured resin. To get more information about resin casting and how it functions, continue perusing this guide.

What is Resin Casting?

Just as the name suggests, resin casting is a casting procedure that entails the utilization of synthetic resin. To have a better understanding of how resin casting works, you should first understand what resin is.

Synthetic resin is any sort of resin that is changed over into solid and unbending polymers by means of curing.

In simple terms, it starts in a fluid state; however, changes over to a solid-state after it has undergone the casting process.

In resin casting, fluid synthetic resin is blended in with a curing agent — commonly at room temperature or close room temperature. Next, the two substances are filled with a mold cavity.

The curing agent at that point changes over the resin into solid polymers, basically solidifying it.

After this synthetic response has completed, the solidified casting is ejected out and expelled from the mold cavity.

What is the Difference Between Resin and Epoxy Casting

Many people tend to confuse these two terms; epoxy vs. resin. Although they are somehow related, they cannot be used interchangeably. So, what is the difference between epoxy and resin?

Resin and epoxy are the two adhesives generally utilized in various applications. They are additionally called plastic adhesives, and they are likewise used to bond together plastics, glass, and metals.

They can be utilized for creative purposes, for assembling things together, repair and maintenance, development, creating, and for both manufacturing and engineering purposes. These plastic polymers are prominent for their solid bonding properties, phenomenal heat properties, and chemical resistance properties.

These plastic polymers are accessible in many different forms. Before comparing two of the regular plastic polymers utilized for different purposes, you have to know a portion of the properties of each kind of polymer.

Applications: Epoxy vs. Resins

The first main difference is in terms of their areas of application. Epoxy resins are curated for the coating applications. On the other hand, resins well-suited for the casting applications.

This is to imply that whereas resin casting can be used for applications such as molds, crafts, and jewelry. Epoxy cannot be used for such functions.

Viscosity: Epoxy vs. Resins

Casting Resins are typically a lot more thinner blends when contrasted with epoxy coating resins. That is on the grounds that packaging resins are normally slower to cure, along these lines produce less heat, which thus, permits them to be poured thicker.

However, this presents an issue when casting resins are utilized in coating applications. Since the blend is more slender, it will regularly run off the edges of the project or require a dam/edge to be worked to hold the material in.

Hardness: Epoxy Casting Resin vs. Casting Resin

In most cases, coating epoxy resins are physically harder than casting resins. Casting resins regularly can change blend proportions, which explain the difference in hardness.

The best case of this is found in casting resin that is utilized as artificial water for a jar. On the off chance that a casting tar is utilized with no adaptability, the jar will at last split as the glass expands and contracts.

In this way, increasingly adaptable blends are essential for these sorts of uses, which can, as a rule, be practiced by shifting the measure of hardener (curing agent) utilized.

However, every single casting resin is unique; explore each with respect to the appropriateness for your individual project. In conclusion, coating epoxies typically offer better scratch resistance than casting resins.

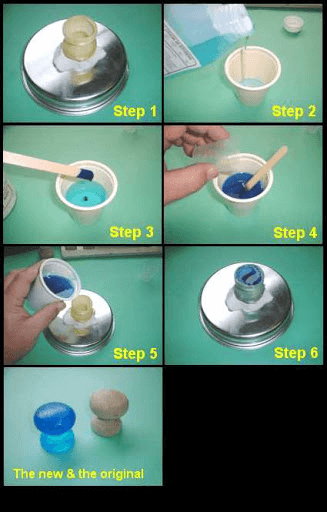

The Resin Casting Process: Step by Step

How is the resin casting for domestic and industrial achieved? Here are the steps to follow when creating resin casting molds.

1. Preparation of the item

This step entails creating a mold. The mold can be created from an already-existing plastic or from a completely new 3D print design.

You can make a mold by submerging the first thing in a flexible material, for example, alginate or silicone elastic. When this is done – and the shell is completely cured – you will be required to cut this rubbery mass open and recover the first model. By then, you will likewise fill the hollow void with another thermosetting material that takes the shape and design of the original object.

For the purpose of accuracy, CAD is used for drawing the designs of the molds. The 3D printed molds will have the same shape and designs with the original item. Once you have the negatives fir the mold, you can proceed to the next steps.

2. Casting the parts

When the negative mold is all set, you can begin casting the final desired parts. The work process is fundamentally the same as the means talked about over:

A two-segment pitch (alternatively pigmented with usually accessible, super-ease dyes) is completely blended, filled the adaptable mold, quickly degassed under vacuum, lastly secured with a level sheet of non-stick plastic – polypropylene or HDPE will do. That is it: the polymerization response kicks in, and in a few hours, the completed parts can be ejected from the mold.

3. Resin casting complex parts

Pondering whether it is conceivable to cast gum complex parts? We are happy to reveal to you that the activity can be accomplished For geometries that can’t be handily cast in single-part molds. For instance, since they don’t have a level base, or in light of the fact that they have articulated undermines – you have to fabricate a mold that comprises of at least two interlocking bits. The thought may sound scaring, and includes a piece 3D critical thinking – yet much of the time, the undertaking isn’t as hard as it appears.

Coloring Clear Resin Casting

Probably you have seen many colored products of resin casting. Have you ever wondered how they were painted. As a manufacturer, can you choose any color for your resin casting?

The fact of the matter is different resin casting companies use different coloring techniques. Let’s have a glimpse at these techniques;

Airbrush paint

The term airbrush color incorporates all paints that are typically utilized regarding airbrushes or are essentially appropriate for airbrushing. These colors are quite water-based and are accessible as acrylic hues or water-based hues.

As opposed to other acrylic paints or water-based paints, the coloring pigments in airbrush paints are very finely organized and amazingly liquid in their carrier medium. Since airbrush paints are additionally simple to blend and have a high radiance, they are commonly utilized all the time for coloring casting resins.

The main problem with this resin casting coloring is the price. It is quite expensive.

Using pigment powder on casting resins

Pure pigment powder can likewise be utilized very well for coloring the casting resins. In any case, you should blend pigment powder with the resin throwing pitch before including the hardener. Typically a base measurement is adequate when using pure pigments.

Pigments can be purchased in every single imaginable variety. You can locate all conceivable coloring varieties from metallic, gleaming colors to matt hues.

Using alcohol-based inks on casting resins

Alcohol-based inks can be dosed into casting resins sparingly because of their high concentration and the high measure of coloring pigments they contain.

A couple of drops are generally adequate to shading the casting resin. Nonetheless, this amount doesn’t just apply to inks on a liquor premise, yet in addition to those on a water premise.

As you can see, each resin casting coloring method needs to be handled with utmost care. If you are not very careful, you may end up messing the whole project.

The good news is you can avoid such traps by using the services of the best resin casting companies in China. They have experts and the right tools that will ensure you get the best results for your resin casts.

What are the Applications of Resin Casing

Resin casting is used for manufacturing collectible and customized toys and objects like planner toys, carport packs, and ball-jointed dolls, just as scale models.

Other delicate products of resin castings include jewelry ornaments and many others. The ability to support different colors is one of the reasons behind the popularity of the process.

In the industrial application, resin casting is used for making singular parts or whole models of items like trains, airplanes or boats. They are by and large created in any volume, from the tens to two or three hundred duplicates, contrasted with injection-shaped plastic figures, which are delivered in a huge number.

Resin casting is more demanding than injection molding, and the delicate molds utilized are worn out by each cast.

The low beginning speculation cost of resin casting implies that specialists and hobbyists can deliver little runs for their own use. If you want resin casting for large industrial applications, then you will have to seek the services of a resin casting manufacturer.

Not sure whether your application will require the use of resin casting? Don’t hesitate to seek advice from experts. They will give you appropriate advice.

Advantages Of Resin Casting

Resin casting seems to be the best way of processing the resins and putting them into proper use. What are some of the benefits that manufacturers can gain from the process?

First, resin casting allows you to explore complex and intricate designs. With this method, you can come up with different designs of the products that you want to cast. This is unlike most casting methods which will force you to adapt to static methods.

Secondly, resin casting allows manufacturers to explore different colors. As we have already seen, there are different methods of painting your resin casting.

It is also important to note that resin casting is a cost-effective method of getting products and their respective parts. You can get many parts without spending too much.

Disadvantages of Resin Casting

The main limitation of resin casting is it may require some high levels of expertise to get intricate designs. This is usually the problem with the DIY resin casting projects. The good news is you always have the option of outsourcing the services to casting resin companies in China.

Where to Buy Casting Resin in China- Roche Industry

We cannot deny the fact that DIY resin casting is a complicated process that is likely to give you a headache. For this reason, you might have opted to buy clear cast resin services.

The surest place to buy this service is from reputable resin casting companies in China. They will ensure that your clear resin casting is done to the utmost precision.

In addition to the accuracy, the companies will ensure that the quality of the resin is good as per the market standards. His will, in turn, elevate the overall value of your products.

It is for this reason that we at Roche Industry dedicate ourselves to providing quality and innovative resin casting services in China. We have been in this business for years, and we have a deep understanding of customer needs.

We use our immense experience to ensure that you get the best results from our casting services. Our quality resin casting services is because of a dedicated team of technicians and of course the high-tech equipment.

Rocheindustry specializes in high quality rapid prototyping, rapid low-volume manufacturing and high-volume production. The services of rapid prototype we providing are professional Engineering, CNC Machining including CNC Milling and Turning, Sheet Metal Fabrication or Sheet Metal Prototyping, Die casting, metal stamping, Vacuum Casting, 3D printing, SLA, Plastic and Aluminum Extrusion Prototyping, Rapid Tooling, Rapid Injection Moulding, Surface Treatment finish services and other rapid prototyping China services please contact us now.

Related source links:

Handbook: The Ultimate Guide To Urethane Casting

Handbook: The Ultimate Guide To Vacuum Casting

Handbook: The Complete Guide To Investment Casting

Handbook: The Ultimate Guide to Metal Casting

Handbook: The Ultimate Guide to Sand Casting