Brass and bronze are two popular metals that are similar in many ways. In fact, they are usually referred to as the ‘Red Metals’ since both appear to be reddish in color and are copper alloys. They also have a wide range of applications which are also somehow connected in one way or the other.

So, what is the difference between bronze and brass? In case you are planning to use either bronze or brass, spare some few minutes to know the differences between brass and bronze.

Contents

History of Bronze and Brass

The first known existence of bronze dates to about 3500 BC and, therefore, the Sumerians and lends its name to the Bronze age. The invention of bronze enabled people to make better metal objects than before.

Products such as tools, weapons, armor, and various building materials, like decorative tiles, made from bronze were relatively tougher and more durable than those made of stone and copper.

Brass came later dates back to about 500 BC. Zinc is practically never found naturally in its pure state, but people had realized that copper smelted with calamine — a zinc ore — produced a golden-colored tarnish-resistant metal that was useful for all kinds of things due partially to its low freezing point and malleability. The zinc itself isn’t seen but is released from the calamine ore by heating and combining immediately with copper.

What is Brass?

Brass is majorly an alloy that consists of copper with zinc added. Brasses can have varying quantities of zinc or other elements added to them. These varying mixtures produce a wide range of properties and variations in color.

Increased amounts of zinc provide the fabric with improved strength and ductility. This can affect the main property of brass. Brass color ranges from red to yellow, depending on the quantity of zinc added to the alloy.

If the zinc content of the brass ranges from 32% to 39%, it’ll have increased hot-working abilities, but the cold-working is going to be limited.

If the brass contains over 39% zinc (example – Muntz Metal), it will have better strength and lower ductility (at room temperature).

Properties of Brass

- Brass often features a bright gold appearance. However, it also can be reddish-gold or silvery-white. A better percentage of copper yields a rosy tone, while more zinc makes the alloy appear silver.

- The brass alloy has higher malleability than either bronze or zinc.

- Brass has desirable acoustic properties appropriate to be used in musical instruments.

- The metal exhibits low friction.

- Brass may be a soft metal that will be utilized in cases where there is a low chance of sparking.

- The alloy features a relatively low freezing point.

- It’s a good conductor of heat.

- Brass resists corrosion, including galvanic corrosion from saltwater.

- Brass is straightforward to cast.

- Brass isn’t ferromagnetic. Among other things, this makes it easier to break away other metals for recycling.

Brass Applications

Brass is mainly used for decoration purposes. This is due to the aesthetic value that it holds. This copper alloy can be easily confused with gold. Most people use brass for making musical instruments.

Other applications of brass include

-In making electronics such as terminals and components of a watch.

-Home and furniture products such as door knobs, fasteners, handles, and even pipes

-Military items such as fasteners, eye bolt snaps, casings, hooks.

-Marine items such as eye bolt snaps, pulleys, fasteners, and bolt snaps

-Outdoor recreation products such as recreation snaps, snap hooks, and quick release.

-Oil and gas industry products such as fittings and valves

What is Bronze?

Bronze is an alloy that consists primarily of copper, among other elements. In most cases, tin is the preferred added element, but arsenic, phosphorus, aluminum, manganese, and silicon also can be used to produce different properties within the material.

All of those ingredients produce an alloy much harder than pure copper.

Bronze is characterized by its dull-gold color. You will also tell the difference between bronze and brass because bronze will have faint rings on its surface.

Bronze is tough and brittle. It melts at a rather higher temperature at 950 centigrade, but this relies on the quantity of tin present within the alloy.

Bronze resists corrosion (especially seawater corrosion) and metal fatigue than steel and is additionally a far better conductor of warmth and electricity than most steels.

Uses of Bronze

Bronze enjoys quite a significant number of applications including but not limited to:

Art. Perhaps the foremost popular use of bronze is in art, particularly as a base material for sculpture. It is the material of choice for sculptors who specialize in metals. This is mainly due to its amazing property, which allows it to expand and cool down slowly.

Construction. Despite being superseded by steel in an array of construction-related applications, bronze still preserves its place in a number of them. For example, many movable bridge components, wheels in worm drives, and turntables for bridges are made from a particular sort of bronze. Modern safety tools like hammers, mallets, and wrenches also are made from a kind of bronze.

Machine Design. There is a score of machine parts that are made from bronze—spur gears, bushings, bearings, valve components, and even valve guides in aircraft engines, all because of its high electrical conductivity, thermal resistance, and low-friction properties.

Bronze Alloys

Phosphor Bronze (or Tin Bronze)

This alloy typically features a tin content starting from 0.5% to 1.0%, and a phosphorous range of 0.01% to 0.35%. These alloys are notable for his or her toughness, strength, low coefficient of friction, high fatigue resistance, and fine grain. Some typical applications of this bronze alloy would be electrical products, bellows, springs, washers, corrosion-resistant equipment.

Aluminum Bronze

This has an aluminum content range of 6% – 12%, iron content of 6%, and nickel content of 6%. These combined additives provide increased strength, combined with excellent resistance to corrosion and wear. This bronze is usually utilized in the manufacturing of marine hardware, sleeve bearings, and pumps or valves that handle corrosive fluids.

Silicon Bronze

This is an alloy that is both in brass and bronze (red silicon brasses and red silicon bronzes). They typically contain 20% zinc and 6% silicon. guinea gold has high strength and corrosion resistance and is usually used for valve stems. Red bronze is extremely similar but it’s lower concentrations of zinc. it’s commonly utilized in the manufacturing of pump and valve components.

How to Identify Between Brass and Bronze

How can I tell whether it brass or bronze? Well, there are various ways of identifying bronze vs brass. These methods include;

Composition

Brass and bronze have the same base element—copper—so in some way, they will look and feel similar. However, their alloying elements are different—brass has zinc, while bronze has tin. Other elements are added to make variants that perform well in specific applications. For example, bronze is often further alloyed with phosphorus, manganese, aluminum, or silicon, while brass is often alloyed with iron.

Despite the variations in their composition, both metals preserve the qualities that are distinct to them, which is why they are doing not transform into completely different materials.

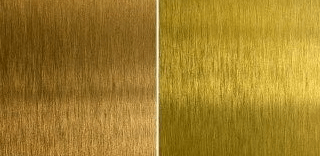

Color

Perhaps the simplest way to distinguish between brass and bronze is by their color. Brass usually features a muted yellow shade, very similar to dull gold, which makes it an ideal material for furniture and fixtures.

Bronze, on the opposite hand, looks nearly always a sepia. This characteristic may slightly change when other elements are added into the mixture, but it’s still easy to inform them apart.

Mechanical Properties

If you actually want to make certain that you are using the proper material, then there’s no better way than to check their mechanical properties. Brass is more malleable and ductile than bronze, and that’s just because tin does a far better job of pinning the copper lattice than zinc. Meaning, the lattices that structure brass can slide more freely on top of every other when the metal is rolled, pressed, or hammered. Due to this, bronze is additionally far more brittle than brass, but it is more durable as brass oxidizes much faster.

Durability

Bronze is hard and sturdy also, but it’s not easily flexed. It does withstand water, which successively makes it immune to corrosion. Although brass is robust, it’s not as durable as copper or bronze. Brass is vulnerable to corrosion and cracking, and it’s not flexible in the least.

Applications/Uses

Brass is used in many of our household accessories, like locks, doorknobs, gears, etc. you’ll also see the brass present and a few electrical and plumbing materials also. Bronze is used in many ship and boat parts and gears. This is mainly because, as stated before, bronze will withstand water, so it can get up to only about anything.

From these differences, you can now tell what metal between brass vs bronze is the best for your application. You are also in a position of how to tell if a metal is brass or bronze.

In case you would like to do 3D printing for brass or bronze, let Roche Industry do the job for you. We are a reputable 3D printing company in China.

References

Red brass vs yellow brass: What are the Differences?

Rocheindustry specializes in high quality rapid prototyping, rapid low-volume manufacturing and high-volume production. The services of rapid prototype we providing are professional Engineering, CNC Machining including CNC Milling and Turning, Sheet Metal Fabrication or Sheet Metal Prototyping, Die casting, metal stamping, Vacuum Casting, 3D printing, SLA, Plastic and Aluminum Extrusion Prototyping, Rapid Tooling, Rapid Injection Moulding, Surface Treatment finish services and other rapid prototyping China services please contact us now.