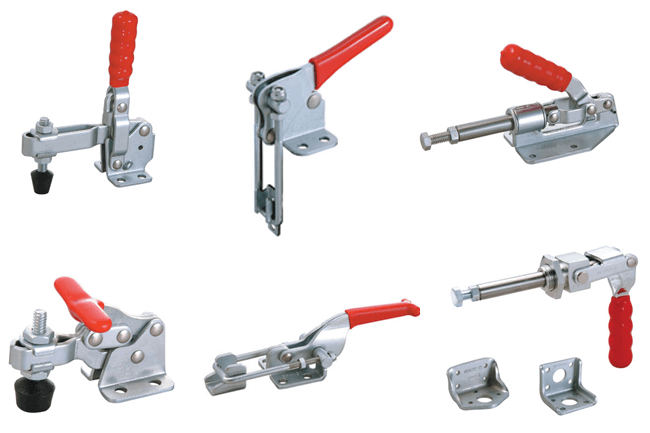

How to Choose the Best Toggle Clamps? The Ultimate Guide

You probably already know that a toggle clamp is a device used to hold an object or piece of load securely. They are also called clamping nails, locking nails, or claw hammers. These clamps have a broad range of applications and can be used in carpentry, metalworking, and even general maintenance tasks around the home.…