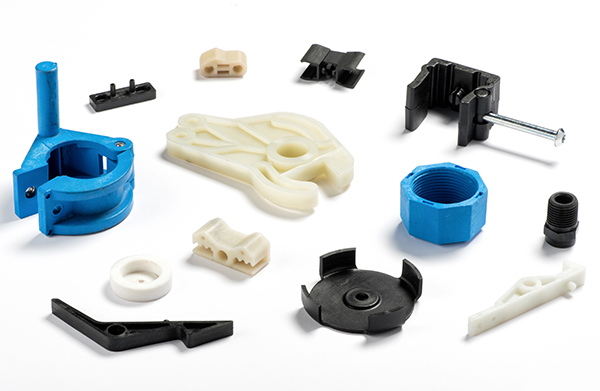

Molded prototypes and low-volume production parts in As Fast As 1 day

See Why Our Customers Love Us

Roche industry team very quick and efficient. Every member of their team I have worked with has been patient and understanding when explaining next steps and process for my product. I look forward to future developments with rabbit product design and my project. Highly recommend!

No doubt, Roche industry is a great company.Thank you Robin, Clark, and the entire engineering design team for your support, creativity, and guidance in taking my project to the next level, thanks a lot for your great efforts. Looking forward to our massive success together!

Absolutely, working hard, responsibility and creativity are the terms that I can define roche industry company. The constant, clear and precise communication with the client on the part of their staff, defines their professionalism. they fulfill what they promise with a delivery on time and with great efficiency. Great job!

How We Do Injection Molding Project Insurance

Sign NDA

We sign the NDA with our customer and also for their projects. Each employee must take pre-enter company training to follow our production flow, so that keep company information security. NDA will be signed on board date. As well as for all our suppliers have to sign NDA. For date security, we use the ISO27001 as the reference. All the data will be securely kept at our own network centre, only the authorized staff can access to the centre and review the data.

Flow Production

We use the work order system to control each process step, timeline for each job is very clear for each team. All of customer requirements will be reflected from the work order. When quoting, our production engineers will review the data and requirement, and provide the DFM if needed. During the production, we guarantee the on-line and off-line inspection to ensure that the parts we produce meet your exact specifications.

Quality control

We are ISO 9001 certified, first article inspection, also support to provide the FAI report.Before the packing, we have the final inspection, which will check all the quality details by our QC. We are very concerns the safety packing. For different sizes and materials production,we will adopt different packing methods to keep products delivery safely. Parts will be marked with labels of item no. and PO no. for customers to recognize easier.

Upload Your designs To Get A Free Quote

Best Injection Molding Service In China

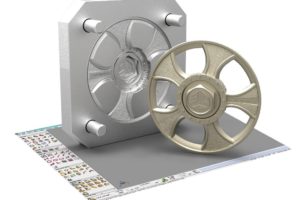

Injection molding is a manufacturing process by which molten material is injected into a mold and cured to create intricate shapes. The method is used to create parts in large quantities for use in a wide range of industries ranging from medicine to aerospace to consumer products.

Roche Industry delivers high-quality, on-demand injection molded parts. Injection molding is the cheapest process to make a plastic part at scale by offering consistent quality for mid-to-high volume manufacturing. Molding also has the highest variety of materials, colors, and configurations compared to CNC machining or even 3D printing. Beyond materials, injection molded parts can have custom cosmetics, polishes, or surface textures.

Roche industry can handle all technical aspects of creating your prototypes and parts, so your team can focus on bringing your product to market. Contact us today to get your manufacturing solution and details.

Advantages Of Roche Injection Molding

Roche Industry provides two injection molding service options—one is best suited for those who need smaller part quantities often associated with prototyping and the other a good fit for those who require larger part quantities common in low-volume production. While the molds themselves are similar, part quantities, lifetime maintenance, quality documentation, and pricing vary depending on which service option is chosen. The right one depends on your project needs. Injection molding is an excellent option for the large-scale production of plastic parts and components. The advantages of using injection molding include:

1. High Efficiency

2. Detailed Features and Complex Geometry

3. Enhanced Strength

4. Ability to Use Multiple Plastic Types Simultaneously

5. Automation to Save Manufacturing Costs

Looking For Injection Molding Service?

Benefits of Working with Roche Industry

1. AS9100-certified

2. All senior designers and engineers

3. Over 10 years of combined experience

4. Develop the right prototype for your needs

5. End-to-end product prototyping under one roof

6. Just In Time delivery of parts

7. Production volume discounts

8. Quality Guarantee

9. 24/7 online service

Let’s Get Started Today!

Send your requirements get instant quote.

Interested In More About Our Manufacturing Services?

Sheet Metal Fabrication

5-10 day lead time

Our sheet metal fabrication service that meets your most stringent requirements. Upload your 3D & CAD files, get an instant quote.

Rapid Prototyping

1-10 day lead time

Our rapid prototyping service that meets your most stringent requirements. Upload your 3D files, get an instant quote.

Pressure Die Casting

5-15 day lead time

Our die casting service that meets your most stringent requirements. Upload your CAD & 3D files, get an instant quote.