Contents

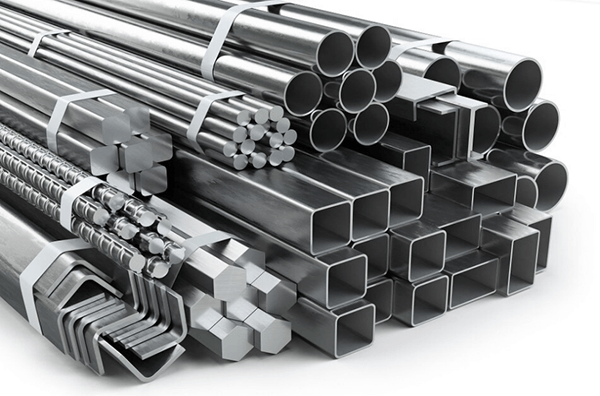

What is Steel?

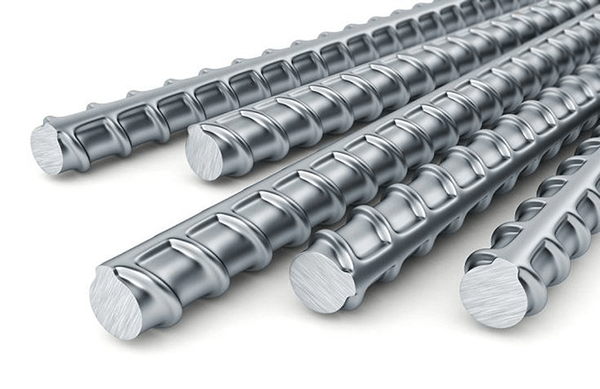

Steel is created by adding carbon to elemental iron. This process increases the hardness, strength, and resistance to impact, corrosion, and temperature. Steel has a wide variety of alloys that incorporate alloying elements like zinc, chromium, molybdenum, and silicon. These elements improve the ability of steel to resist corrosion, which is why it is mostly referred to as stainless steel. The amount of chromium added to steel determines its resistance to corrosion. It is hard to generalize the properties of steel since it exists in so many types and gauges.

To be specific, most alloys of steel are dense and hard but can still be worked. Steel also responds to heat treatment, which gives it different properties depending on the process and the type of steel. Additionally, steel is an excellent conductor of both heat and electricity. Some examples of steel are susceptible to rust because of the iron component. However, this problem is addressed by the addition of chromium to make stainless steel.

What is Titanium?

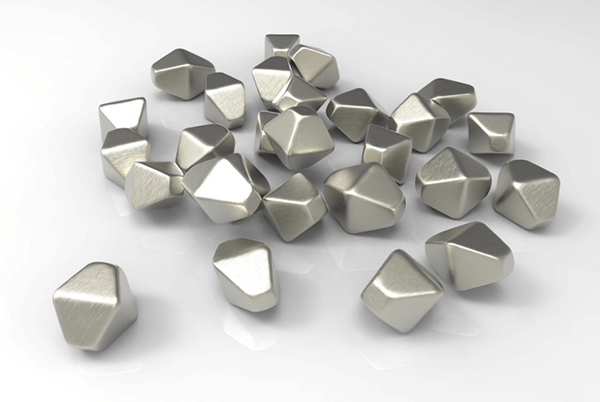

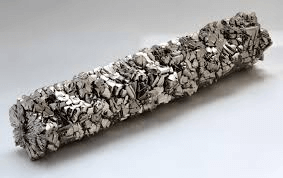

Titanium is the fourth most abundant metal on earth. However, it is infrequent to find titanium in elemental form or high concentration. Additionally, titanium is very difficult to purify, which makes it more expensive.

Titanium has a density of 4.51g/cm3, which means it lightweight compared to other metals. Additionally, a pure form comes in silver-grey color. It is essential to note that titanium is not magnetic. Like many metals, titanium can occur in an elemental form or a wide variety of alloys. These alloys are often strengthened and more resistant to corrosion. Most alloys of titanium are used in the aerospace, structural, and applications that require high-temperature resistance. Elemental titanium is often used as an alloying element.

Comparing Titanium vs Steel

Choosing between steel and titanium depends on the application at hand. This section compares the mechanical features of steel and titanium, which helps determine how each metal can be specified. However, the best comparison of these metals is based on different types of alloys instead of generalized data.

Steel Vs. Titanium: Density

Density can be used to determine the weight of each metal. As observed earlier, titanium is more lightweight than steel, weighing almost half the weight of steel. This property makes titanium suitable for applications that require strength and lightweight, for instance, in the aerospace industry. On the other hand, the density of steel is beneficial when used in places such as vehicle chassis.

Steel Vs. Titanium: Elasticity

The elasticity of a material describes how flexible it is. This measure is sometimes referred to as Young’s modus. This property is essential in understanding how a material responds to impact, whether it bends or warps without achieving plastic deformation or not.

In this respect, titanium has a low elasticity, which means the material flexes and deforms when under pressure. This feature also makes it hard to machine titanium. On the other hand, steel has a higher elastic modus and can be machined with less hassle. This property makes steel suitable for making knife edges because it can break without bending under stress.

Steel Vs. Titanium: Tensile Strength

In terms of the tensile strength, steel is much more robust than titanium, unlike most people believe that titanium is more potent than most metals. This feature makes steel a widely used metal compared to titanium. However, titanium is equally more durable as steel and has almost half the weight of steel. This makes titanium stronger per unit mass compared to steel.

In applications that require overall strength, steel is most preferred because most of its alloys have higher yield strength compared to other metals. If you are solely looking for strength, then steel should be your go-to metal. However, if the project requires strength per unit mass, then you go for titanium.

Steel Vs. Titanium: Elongation At Break

This feature is the measure of how much a material stretches before it breaks. A higher elongation at break implies that material stretches more before it finally breaks. In other words, if the metal has a higher elongation at break, then it is more malleable. Titanium is very ductile and will stretch almost half its length before breaking. This feature makes titanium hard to machine. On the other hand, steel has a wide variety of alloys with low elongation at break, meaning it harder and brittle.

Steel Vs. Titanium: Hardness

Hardness is considered a relative value that refers to how a material responds to scratching, denting etching, among other impacts applied on its surface. The hardness of a metal is measured using an indenter machine. Titanium is hard but does not reach the level of steel. This does not mean that titanium deforms easily. On the contrary, titanium forms a dioxide layer, which is hard and protects the metal from scratches. Steel is hard and does not scratch easily. This makes it suitable for applications that require exposure to rough conditions.

The bottom line

Comparing steel to titanium is the best way to determine the best material to use for a project. However, it is essential to understand that the material to choose between steel and titanium depends on the application at hand.

The differences between titanium and steel can be derived from various aspects like mechanical properties. These differences make it easier to understand each metal well.

Related source links:

18/10 stainless steel VS 18/8 stainless steel: What Are the Differences

Aluminum vs Stainless steel: What are the Differences?

Carbon Steel vs Stainless Steel: What is the Difference?

304 vs. 316 stainless steel: What are the Differences?

420 Stainless Steel vs 430 Stainless Steel: What is the Difference?

Surgical Steel vs Stainless Steel: What are the Differences?

Rocheindustry specializes in high quality rapid prototyping, rapid low-volume manufacturing and high-volume production. The services of rapid prototype we providing are professional Engineering, CNC Machining including CNC Milling and Turning, Sheet Metal Fabrication or Sheet Metal Prototyping, Die casting, metal stamping, Vacuum Casting, 3D printing, SLA, Plastic and Aluminum Extrusion Prototyping, Rapid Tooling, Rapid Injection Moulding, Surface Treatment finish services and other rapid prototyping China services please contact us now.