Trivex and polycarbonate have been in existence for ages. However, there are still some heated debates, misconceptions, and confusion about how the two materials stack up against each other. This article will down the facts about both Trivex and polycarbonate, put them to the test. In the long run, this post aims to put the question about how Trivex and polycarbonate compare to one another to rest. First, it is essential to take a look at the two materials separately and identify their distinctive attributes. Trivex vs polycarbonate: What are the Differences?

Contents

What is Polycarbonate

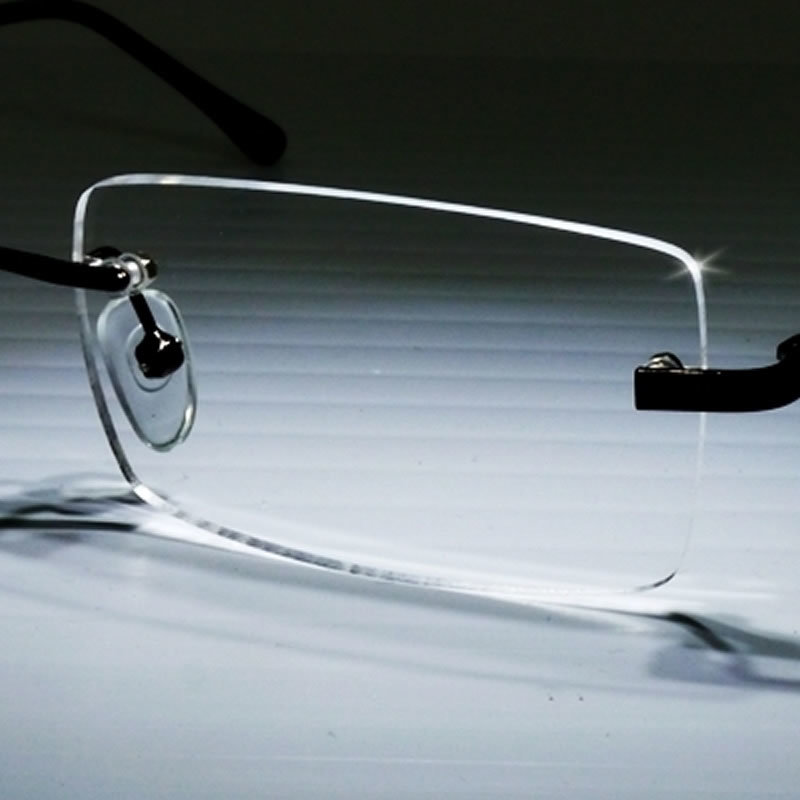

Polycarbonate was first introduced to the optical world in the late ’70s as an ophthalmic lens. Due to its superior resistance to impact, polycarbonate has enjoyed a wide array of applications, especially in eyewear. Polycarbonate lenses are thinner and lightweight than other plastic or glass materials. This feature is impacted by a higher refraction index and lower specific gravity. Other specifications like protection from direct UV rays make polycarbonate ideal for use in lenses. Polycarbonate is even more popular because it is available in high quantity as a result of large scale production.

Polycarbonate does not go without drawbacks. In most cases, polycarbonate lenses lack optical quality because they possess less clarity and transparency, like other forms of plastic such as acrylic and Trivex. Additionally, polycarbonate has the highest chromatic aberration, which is also above any other lens material.

Polycarbonate also has a high likelihood of cracking when drilled because it has a low tensile strength. This shortcoming makes it a challenge to use polycarbonate in drill-mount frames. However, users are advised to conduct their homework well and put the material through their tests to determine if it is suitable for particular uses.

What is Trivex

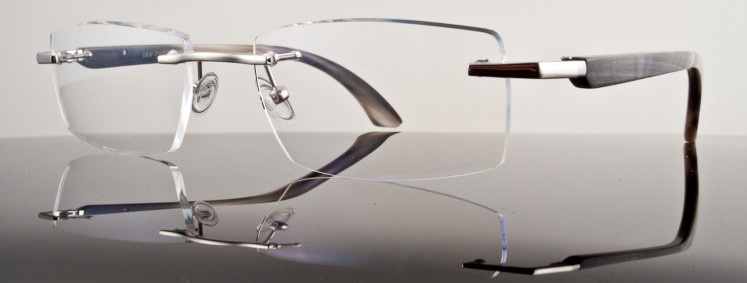

Trivex became the only material to pass the FDA impact resistance test as a lens material besides polycarbonate in 2001. Additionally, Trivex is commonly used as a lens material because of its high-velocity impact and has been increasing in application and market availability. Compared to the polycarbonate (refractive index of 1.58), Trivex has a slightly lower refractive index of 1.53. However, it is the lightest lens material in the market and doubles up as perfect protection against UV rays.

On the other hand, Trivex has a better optical superiority with an Abbe value of 45. Conversely, it is more suitable for use in drill-mount frames because of its high tensile strength, which makes it resistant to cracks when drilled.

Trivex vs Polycarbonate

You are now well-versed with some essential information about Trivex and Polycarbonate. What follows is a side by side comparison of the two lens materials to determine how they weigh up against one another. The comparison is based on the features of Trivex and polycarbonate.

How does Trivex compare to polycarbonate?

The thickness of individual material

In terms of thickness, polycarbonate boasts of a higher refractive index of 1.58 compared to 1.53 of Trivex. This means that polycarbonate lenses are thinner than Trivex lenses. Despite the difference, you may not be able to notice that Trivex is ten times thicker than polycarbonate.

The weight of Trivex vs. Polycarbonate

Trivex lenses are lighter compared to polycarbonate lenses. That is because Trivex has a lower specific gravity compared to polycarbonate. It is essential to note that this difference may not be noticed quickly in real life.

The optical clarity

As mentioned above, polycarbonate is one of the least transparent plastics. Additionally, polycarbonate has a higher chromatic aberration with an Abbe value of 29. On the other hand, Trivex has a higher Abbe value and lower chromatic aberration. This information means that Trivex lenses offer the sharpest peripheral vision. This difference is, however, subjective.

Resistance to impact

Both polycarbonate and Trivex have high resistance to impact. In fact, the two lens materials possess the same resistance to impact. However, this can change drastically depending on the type of coating used on individual material.

Protection against UV rays

Both polycarbonate and Trivex offer 100% protection against UV rays. That means you do not need special UV-blocking lens coating to be protected from the harmful rays of the sun.

Availability in the market

Polycarbonate and Trivex do not occur naturally. They are both manufactured from different compounds and are available in a wide variety of designs and models.

Cost of the lens materials

Trivex lenses are more expensive than polycarbonate lenses. However, the prices of these lens materials differ significantly in the market.

Scratch Protection

As noted above, both polycarbonate and Trivex have similar impact resistance, which is also higher than other forms of plastic. However, these materials are often soft (can absorb energy without cracking. In other words, they are not rigid and stiff.

The flexibility of polycarbonate and Trivex means that they require protection from scratches. The best of doing this is by adding scratch-resistant materials on the surface of the lens material as a coating. The scratch-resistant coating also enhances the strength of both Trivex and polycarbonate.

In a nutshell

Trivex and polycarbonate both have similar impact resistance and UV protection. However, Trivex has a lower refractive index and is, therefore, slightly thicker and lighter than polycarbonate. Trivex also has the best optical quality and is more suitable for use in drill-mount frames. However, these differences are only notable on papers.

When carrying out a test to compare Trivex and polycarbonate, you will discover that the performance differences of the two lens materials are negligible. If any coating is added to either polycarbonate or Trivex, the differences become more manifest, especially in terms of impact resistance.

The comparison of prices of polycarbonate and Trivex requires direct analysis. For instance, compare the cost from the same dealer or the price of the same quantity. The difference will be less than on papers even though polycarbonate will still be more affordable than Trivex.

When it comes to deciding on one lens material to use, you need to determine your requirements before jumping on either polycarbonate or Trivex. You will find out that the two lens materials are used in different ways and for different purposes.

Related source links:

Handbook: Everything you need to know about PETG

PETG vs ABS: What are the Differences?

PETG vs PLA: What are the Differences?

Polycarbonate vs Acrylic: What are the Differences?

Nylon vs Polyester: What are the Differences?

White paper: The Complete Guide To thermoforming

Everything You Need to Know about PVC Pipe Sizes

Rocheindustry specializes in high quality rapid prototyping, rapid low-volume manufacturing and high-volume production. The services of rapid prototype we providing are professional Engineering, CNC Machining including CNC Milling and Turning, Sheet Metal Fabrication or Sheet Metal Prototyping, Die casting, metal stamping, Vacuum Casting, 3D printing, SLA, Plastic and Aluminum Extrusion Prototyping, Rapid Tooling, Rapid Injection Moulding, Surface Treatment finish services and other rapid prototyping China services please contact us now.