Contents

Vise Overview

Setting up a workshop the next task is to equip it. You would like your workshop to be fully equipped with an array of tools and equipment that will make your work easy. One of the pieces of equipment that you are likely to buy is the vise.

Whether you specialize in woodwork, metalwork, or both, you will appreciate the importance of a functional vise in the workshop.

Which is the best vise for me? Where can I buy a vise and how do I know that my vise is good? This guide provides the best answers to these questions.

Here is a comprehensive guide that you can use for buying the best vise in China.

What is a Vise for Workshop?

As a workshop tool, a vise is usually categorized under the holding tools. These are tools and equipment that are used for holding workpieces to allow the operator to work on a specific object.

Well, that is exactly what a vise does. It is equipment that is specially designed to hold an object securely so that you can work on it.

A typical vise has parallel jaws which press against each other to hold the workpiece or object that you are trying to work on.

The act of securing an object will ensure that you can focus on the workpiece or object in question. You won’t have to worry about the issue of keeping the object stable or even your safety. You will also be able to keep a safe distance while working on an object.

How Does a Workshop Vise Work?

A vise has two jaws that are positioned parallel to each other. These jaws down the primary work of holding or clamping your workpiece so that it remains, tight, secure, and stable in your desired position. In most vises, one jaw remains stationary while the other can be moved.

On the other side, a threaded screw controls the movement of the movable jaws. This screw runs through the vise and is also connected to the main handle equipment.

So, you will apply some pressure on the handle and the pressure will, in turn, be transferred to the threaded screw which will move the jaws. The screw rotates clockwise and anticlockwise directions to move the jaws.

The clockwise rotation will move the jaws towards each other to clamp the object. Anticlockwise rotation will move the jaws against each other to release the object. You can tighten the screw to increase the grip on the object so that it remains stable to allow you to work on it safely.

The video below gives a clear illustration of how a vise works

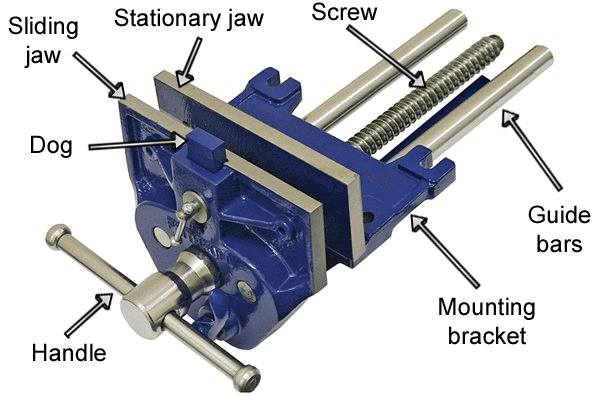

Parts and Components of a Vise

As we have seen, various components are involved in making a vise execute its role in a workshop. Does your vise have all the necessary components? Here are the main parts and features of a vise;

Jaws

A typical vise has two jaws. One is stationary while the other one is sliding or movable. The jaws are made of strong metal since they are required to exert a tight grip on the object. However, some jaws are made of wood. It all depends on the area of application for the vise.

In terms of the design, the front face of the jaws is flat. This ensures that it does not leave any indentation when clamping different materials. The face of the metal jaws may have some pads also to protect the target object.

Screws

The work of the screw is to control the movements of the jaws. It determines whether the jaws should be opened or closed. They come in different lengths and thread formations. Usually, the screw length will determine the maximum clamping capacity of the vise.

The screw is threaded to offer maximum strength when clamping an object. The entire body of the screw runs through the vise. It is connected to the sliding jaw. This means that the slightest action on the screw will affect the movement of the jaw.

A mounting bracket helps to keep the screw in position. The other end is connected to the vise handle onto which you apply force to affect the movement of the screw.

Vise handle

You will be doing most of the control actions on the vise handle. It is connected to the screw and makes it easy to control the vise. The handle is made of user-friendly materials such as wood and polished metal making it comfortable on the hand.

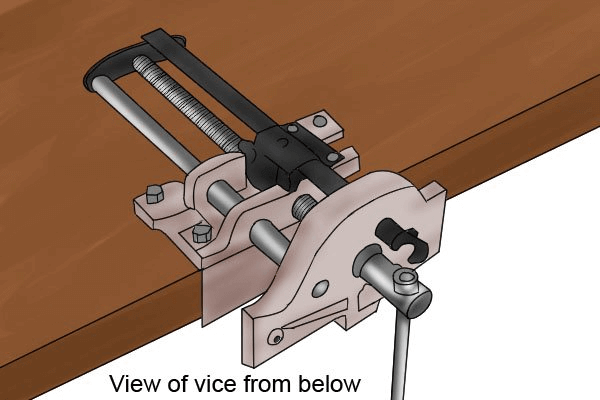

Mounting bracket

The bracket attaches the vise to the workbench. It is designed and shaped to fit tightly and remain stable on the bench.

Guide bars

The bars provide the screws with additional support protecting them from mechanical damage. The guide bars also support some extra weight from the sliding jaw.

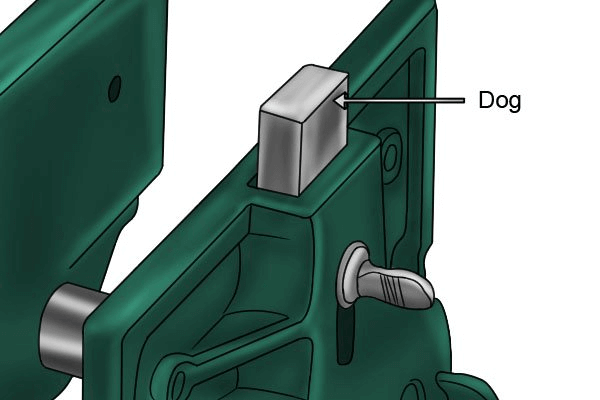

Dog

This is a common feature in most modern vises. The front dog provides extra clamping support on the workpiece, especially when used with a bench dog. The dog also prevents unplanned movement of the jaw by providing some form of obstruction. It also prevents the workpiece from moving especially when it is positioned horizontally to the vise.

Toe-in

This is another optional feature that is in most modern vises, especially the ones used in woodwork workshops. Its core purpose is to prevent racking on the wood due to the force from the jaws. This is common when the jaws exert unequal pressure on the object.

Applications of Vise

Vise have a wide range of applications in different industries. Here are some of the areas in which vises are commonly used;

Wood work

This is a field that witnesses widespread use of vise. Carpenters depend on the vises for making simple and complex woodwork products. You will need to clamp your workpiece in position when doing those finishing touches such as polishing a product. A vise will also be necessary when you are joining pieces of wood to form a product.

Metal works

There are various aspects of metal works that require proper clamping. No other equipment can do this job better than an agile and well-constructed vise.

Electrical field

The process of making and refining electrical products may require some clamping and supporting activities. A vise is usually used when cutting conduits for electrical installations.

Product manufacturing

Companies that deal in manufacturing and assembly of products use vises for various purposes. A vise can be used for holding a product whenever you are doing final touches such as sanding and painting.

Types of Vises for Workshop

As we have seen, there are different applications of vises. This directly implies that vises are not all the same. They come in different designs and construction. Vise manufacturers ensure that each design will work perfectly for a specific area of application.

Let’s look at some of the common types of vises that you may consider buying;

Woodworking vise

As the name suggests, this type of vise is specifically designed for the woodwork applications. You are likely to find it in carpentry shops and other industries that deal in wood-related products. It is usually attached to fixed workbench.

The jaws of most woodwork vises are made of wood though some are made of metals for heavy-duty applications. Also, most of these vises have retractable dogs that hold the workpiece against the bench.

A woodwork vise can either be face vises or feature end vise. The face vise can be attached at the front or near the left and side of the workbench. Its position of installation will depend on the operator’s preference. End vises are usually installed at the very right end of the workbench.

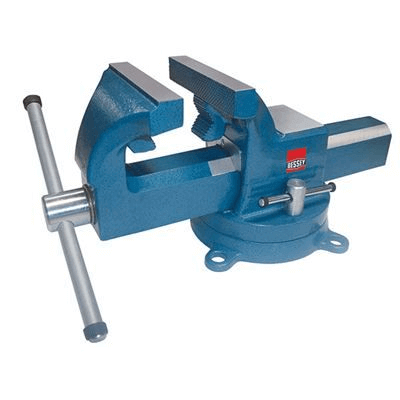

Engineer’s vise

Also known as machinist or metalworking vise, this type is commonly used for the applications involving the use of metals. It is well-designed for holding metals. This is evidenced by its construction that mainly features metallic components.

Cast steel and cast iron are just some of the metals used for making this vise. They are known for their high tensional forces. Metalworking vises support various activities such as cutting, filing and even drilling of metal objects.

The jaws of metalwork vises are serrated to ensure that deliver tight grips on the objects. They are also separate so you can replace them when necessary.

Heavy-duty vises

These vises are similar to the metalwork vises only that they feature more reinforcement to be suitable for the heavy-duty applications. They are made of steel jaws and their steel screws and slide bars. Other than factories, machine vises are also used by hobbyists.

Yoke vises

Also known as hinged vises, they are mainly used for plumbing activities. They have screws which help to clamp pipes for various operations such as cutting, drilling and threading.

Vacuum vises

These vises are mainly used for sensitive applications that require high levels of accuracy and preciseness. They are used for holding circuit boards and even models for major products. Jewelers also use these vises for holding their pieces of jewelry.

Other types

There are many other minor types of vises including

- Clamp vise

- Hand vise

- Rotary vise

- Suction vise

- Off-center vise

- Leg vise

- Jewelers’ vise

- Saw vise

Technical Specifications to Consider When Buying Vise

So you want the best vise that will be functional in your business? The first thing that you should look at is the type of the vise Ensure that you choose the right type from the list above. From there you can proceed to look at different technical specifications which include;

Jaw width

The width of the jaw will affect the functionality of the vise. It determines the ability of this holding equipment to hold onto a workpiece. Since the vises come in different width measurements, you can choose the one that matches your application.

Jaw opening

Jaw opening is usually determined by the length of the screw. Find out the maximum width that the jaws can open to hold onto an object. This factor will determine whether the vise will be used for holding large or small objects.

Ease and mode of mounting

You may also consider the process of mounting the vise onto a workbench. Will you be able to mount it with ease or will you need to get extra accessories for mounting? Most vises come with bolts which you can use to mount. Heavy-duty vises may require more reinforcement to be mounted.

Pipe jaw or bench jaw?

Some vises are ideal for holding onto pipes while others are mounted on benches. Choose vise with serrated jaws for pipes. It can also hold onto rectangular objects. It will be better to buy one whose jaws are for pipe and bench applications.

Vise Manufacturers and Suppliers in China

After gathering all the vital information, the next step is to buy vise for sale in China. And where else can you get them if not from the best manufacturers and suppliers? Choose a manufacturer that has the potential of delivering the best vise.

What is the price of the vise in China?

Usually, the cost will depend on the specifications of the vise. This is to say that there is no universal price for the workshop vises. Compare the specifications and see whether they match the price. The price will also depend on the vise manufacturer and suppliers.

The best place of knowing about the price is calling the vise manufacturer directly for detailed information. As a reliable and experienced vise manufacturer in China, we will send you quotations for our different vises. If you want some customizations, we inform you the cost for the process.

Conclusion

I hope that this guide has given you all the important information that you need to know about vise. From the different types of vise, you will choose one that is perfect for your field. Thereafter you can contact us and place your order.