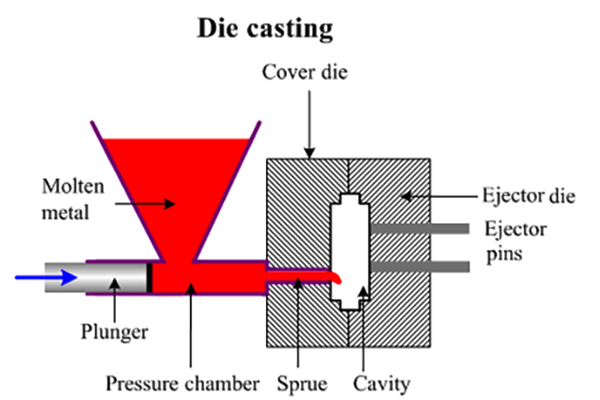

Die casting is a metal casting process that is characterized by forcing molten metal under high pressure into a mould cavity. The mould cavity is created using two hardened tool steel dies which have been machined into shape and work similarly to an injection mould during the process. Most die castings are made from non-ferrous metals, specifically zinc, copper, aluminium, magnesium, lead, pewter, and tin-based alloys. Depending on the type of metal being cast, a hot- or cold-chamber machine is used.

Are you looking for die casting companies in Australia? We have compiled the best 10 die casting companies list for you to pick as below:

Contents

Australian Die Casting Association

The Australian Die Casting Association, (also known as ADCA), is the focal point for companies and people in the industry to keep informed of new developments, technology, opportunities and contacts.

The objectives of the Association are to promote:

the advancement of the Australian die casting industry

the education and development of people in the industry

co-operation between the Association, the industry and Government

These objectives are met through:

Regular branch meetings and plant visits

Seminars, workshops and conferences

Distribution of Notices and Magazines

development and delivery of education programs

support for research and development programs

Address: C/O 26 Villas Road, Dandenong South, VIC 3175, Australia

A.F. Diecasters

Founded in 1966, Australian-owned and operated, A.F. Diecasters, continues to manufacture flexible, custom-designed Zinc and Aluminium diecast products to a myriad of clients both local and international. Today, the company is led by owner Peter Bates and operates out of Huntingdale, Victoria.

A.F. Diecasters boasts a team of qualified staff with more than 30 years’ experience in the Zinc and Aluminium diecasting industry.

With unmatched expertise in the field, we have excellent knowledge in product design from the conception to the finished product.

Furthermore, our team provides technical support and guidance with the laying out of tooling, including gating, locating runners and risers that can, in turn, affect the quality of the castings required for the application.

Overall, A.F. Diecasters is a customer-first driven business, where the clients themselves, can liaise directly with the owner. Quality is our number one priority from product to service.

Address: 32 Clifford St, Huntingdale VIC 3166, Australia

Adarsh Australia

Adarsh Australia is a WA owned and operated manufacturer, fabricator and importer of component parts. We have a dedicated, core team of engineering and manufacturing staff and are geared for short to long runs. Rely on us for very fast turn-around manufacturing at high quality and discover how we are the local price leaders.

Most of all, ask our customers. They tell us the reason they keep coming back is due to our reliable service!

Address:6 Crocker Drive, Malaga 6090, Western Australia

Mett Manufacturing

The Mett Group (“Mett’) includes Mett Holdings Pty Ltd, Mett Pty Ltd, Australian Die Castings Pty Ltd and W & G Westphal Pty Ltd Trading as Hilton Tooling. Mett is engaged in the manufacture of automotive components and is the leading aluminium high pressure and gravity die caster in Australia. The company was established in 1983 with the goal of building and maintaining a state of the art, manufacturing facility.

Today, Mett employs over 200 people and growing at its Noble Park base in Victoria.The company’s plant maintains its primary die casting manufacturing capabilities whilst undertaking precision high speed CNC machining and complex automated product assemblies.

Mett strives to support demanding customers within the automotive industry as well as other sectors through the provision of high quality tested products at competitive pricing and a commitment to continuous improvement with a strong focus on customer service.

The company’s operations are supported by its sister company Hilton Tooling, which is internationally renowned for its technology and capabilities in the design and manufacture of precision tooling. Through this connection, Mett is able to further service customer projects from tool design, 3D-modelling, prototyping and solidification simulation through to CAD/CAM based die manufacturing.

Mett is able to support customers’ assembly requirements from a simple tube insertion process to a fully automated assembly line required by complex sub assembles. All our assembly equipment is designed as well as built in-house with full traceability and error proofing.

It is these capabilities that have seen Mett achieve numerous awards including the prestigious GM ‘Supplier of the Year’ awarded on eight separate occasions and recently the Victorian Export Award.

Address: 20-38 OVERSEAS DRIVE, NOBLE PARK, VICTORIA, AUSTRALIA 3174

Light Alloy Engineering

Light Alloy Engineering specialises in Gravity Die Casing, also known as Permanent Mold Casting. A wide range of aluminium alloys are able to be cast in this process, enabling designers to tailor an alloy to their specific requirements

LAE has been operating for over 25 years, and supplies aluminium castings for many end users, including truck body manufacture, components for building and construction, mining, commercial and domestic furniture and all general engineering applications.

LAE has in-house CAD design and CNC capability, enabling us to take a project from the original concept, assisting with casting design, through to tooling design and manufacture and on to production of castings. Our ability to produce our own shell-cores gives us great flexibility in casting design

We also have in-house heat treatment facilities which enable us to supply castings in the T5 or T6 condition, or other heat treated conditions to suit your needs.

Address: 38 Lamana St, Mordialloc VIC 3195, Australia

Diecast Australia

Diecast Australia has been one of the go-to die casters in Australia for many years, and in that time the company has evolved into becoming one of the key players in the Australian Aluminium and Zinc Die Casting industry.

As industry in Australia shifted from producing everything in house to outsourcing or offshoring, Diecast Australia saw the opportunity to take advantage of the change and turn it into a competitive advantage.

By partnering with companies as a key part of their value chain and supplying a complete end to end solution for the creation of premium Aluminium and Zinc die cast products, companies could divest the expenses surrounding the machinery, staff, overheads, material costs, etc., and then be able to work on a fixed price per unit allowing maximisation of Profit, Quality, Continuity, Reliability and Price.

To us, a great die casting company is one that provides a complete solution, and we are proud of the results of our process creates for our customers. In reality we are one of the only companies die casting in Australia that has CNC Machines, Powder Coating, Mass Surface Finishing and freight capabilities that can be customised to your specific requirements. Our philosophy is, you tell us what you want, when you want it and we’ll look after the rest.

For years Diecast Australia has been based in Melbourne,situated close to freight routes and major highways, so moving products around, pick-up and delivery is super easy and can be carried out in a timely fashion.

Address: 8 Pitt Street, Reservoir VIC 3073, Australia

Alliance Connect

Alliance was established in 2005, however the Vorrath family has been in the metal business for more than 50 years. The company was originally an amalgamation of a number of well-respected casting businesses coming together under one banner to provide a broad range of casting and finishing services.

Alliance has continued to grow, expanding it’s customer base, its products and it’s services while still maintaining an unyielding focus on ‘doing the right thing’ for all its customers.

Alliance Connect prides itself on providing a broad range of high quality services from initial design and pattern making through to determining the most appropriate casting methods (sand, die casting) and ensuring the final product is finished to meet the highest quality standards (link to quality page)

Alliance Connect provides a ‘one stop shop’, an end to end range of services to meet all our customer metal needs.

Address: 51/53 Lathams Rd, Carrum Downs VIC 3201, Australia

Excelsior die casting

Excelsior has been a reputable Diecaster since 1987, now specialising in High Pressure Diecasting using Aluminium and Zinc Alloys.

Excelsior has a diverse range of customers and products including, White Goods, Electronics, Camera Support Equipment, Train Braking Systems, Electrical Lighting, Building Industry, Commercial Solutions, Automotive and Excelsior is a small diecasting facility, catering for short run-Single cavity tools, as well as high volume production runs using multi-cavity tools.

The machine capacity of the company ranges from 225Tonnes to 650Tonnes Cold chamber machines in Aluminium and 160Tonnes Hot chamber machine in Zinc.

Excelsior uses Visi-Track shot monitoring system for machine set up and maintenance diagnostics.

The expertise of Excelsior is a one stop shop that can assist customers from product concept design to production completion. With the ability to help customers in tool design, Excelsior can achieve both a win win situation for the customer and plant production yields.

Excelsior’s employees have the ability to satisfy customer needs by understanding at an engineering level to quickly resolve quality related issues.

Through having an understanding of the industry, Excelsior is able to offer good customer support and delivery times. Excellent customer service is maintained through quick and accurate decisions on production, quality and communication with the support and help of the Factory Manager, who is a hands-on engineer and toolmaker.

Excelsior has been quality assured for over 12 years and is currently accredited to ISO 9001, enabling us to maintain consistent quality to our customers.

Excelsior has been a member of the Australian Die casting Association for 20 years and has had an active representative on the ADCA Committee for more than 15 years.

Address: 74-80 Derby Street Silverwater NSW 2128, Australia

Quality Castings

Quality Castings is your portal to Supply from foundries in Malaysia, Thailand, Indonesia and China. Our extensive knowledge and experience of the cast metal products industry in Asia and our foundry to your door service capability make us your ideal casting supply partner. Benefit from globally competitive pricing from foundries in low cost manufacturing countries.

Quality Castings controls the manufacturing at the foundry by controlling all manufacturing processes including casting methods and metallurgy. Castings are inspected prior to shipment. We know the best foundry for your product based on requirements. We arrange machining either offshore or in Australia and have full testing facilities available at our premises in Sydney. We look after all shipping and customs removing that burden from your office.

Quality Castings has legal manufacturing agreements with our supplier partner foundries protecting your intellectual property. We can freight your patterns when necessary or can have them made in China or Malaysia.

Move to globally competitive pricing by sourcing your cast metal products from globally competitive suppliers while Quality Castings looks after your requirements.

Address: 3/9 FITZPATRICK STREET REVESBY 2212 NSW, Australia

Hycast Metals

Hycast is a lot more than “just another investment casting company”. The company offers the full range of technical skills necessary to ensure precision investment castings are managed effectively from design through to utilization.

Hycast has manufactured engineered castings, for the full spectrum of industries.

Hycast has completed prestige architectural projects across the world, including Dubai International Airport Terminal 3’s distinctive tear drop windows and Hong Kong’s One Island East foyer support structure, including 220 kg distinctive and unique vierendeel truss elements.

Hycast is able to coordinate all the engineering and metallurgical services required to produce custom made investment castings for glazing support systems.

Our castings have literally been around the globe. Hycast manufactured the high strength stainless steel castings and supplied Fleming Self Steering with the components for Jessica Watson’s “Ella’s Pink Lady” on her record breaking circumnavigation in May 2010. Jessica steered a fine course!

In addition to Investment casting, Hycast manufactures centrifugal spun castings. These casting can be made in materials and dimensions, not readily available from standard stock suppliers.

Address: 404 Woodpark Road, Smithfield NSW 2164 Australia

Conclusion

How to choose right die casting services company is very important, Without looking further, we’re also die casting services company in China. Rocheindustry aim to give purposeful reviews and information that is bound to save your time. In case of any questions, inquiries, or even comments, reach out to us.

Remember, a happy client is a happy company.

If you’re looking for die casting services with competitive price in China please contact us as below button.

Related source: White Paper: The Complete Guide To Die Casting