Contents

If you have been shopping around for PVC you might have heard the term “schedule”. Despite its deceiving title, the schedule doesn’t have anything to try to to with timing issues. A PVC pipe’s schedule has got to do with the thickness of its walls. One of the things that you might have noticed is that schedule 80 pipe is slightly more costly than schedule 40.

Though the surface diameter of a schedule 80 pipe and a schedule 40 pipe are the same, 80 pipe has thicker walls. This standard of measuring pipe came from a requirement to possess a universal system for pertaining to PVC. What are the Differences between Schedule 40 PVC vs Schedule 80 PVC?

Since different wall thicknesses are beneficial in several situations, the ASTM (American Society for Testing and Materials) came up with the schedule 40 and 80 system for classifying and differentiating these two common types.

What do you mean by schedule 40 PVC?

As we have already mentioned, the schedule is a term that is used to refer to the thickness of the PVC pipe. The higher the schedule the thicker the pipe.

In this case, schedule 40 refers to the PVC pipe that is 0.154 inches thick. This is a common PVC pipe that is used for a wide range of applications.

PVC Schedule 40 pipe is mainly used for drainage and lower pressure water flow applications.

This PVC pipe can handle up to 140 degrees F in temperature. The pipe lengths are available standard 10’ or 20’ sections.

PVC schedule 40 pipe is out there in plain end or belled end that doesn’t require coupling for installation. Pipe sizes range from ½” through 24” in diameter.

Easy installation and lots of application uses are only two great benefits of PVC pipe. Schedule 40 PVC pipe is designed to handle fluid pressure applications also as many chemicals and corrosive materials.

It is mainly recommended to use a robust, sturdy primer and cement when installing a schedule 40 pressure pipe.

A standard medium set PVC glue is suggested for sizes up to 12” in diameter. When gluing pipe over 12” you should use a slow set glue as it can give adequate time in getting connections done tightly and securely.

Schedule 40 PVC pipe adheres to ASTM D 1784 and is ANSI, NSF 61 approved for potable water service.

What do you mean by 80 schedule PVC

Schedule 80 PVC pipe denotes the PVC pipe of standard wall thickness. The thickness of the wall is liable for the pressure capacity of the pipe.

Schedule 80 PVC pipe is rated for a minimum of 200 psi at 73 degrees Fahrenheit. This is often well above the 65 psi found in standard water systems. It is also well above the 140 psi rating standard in Schedule 40 PVC pipe. It is, however, but the 370 psi of Schedule 120 pipe.

What is schedule 80 PVC used for?

Because schedule 80 PVC may be a thicker pipe, it’s usually is used for applications that are commercial or industrial in nature. These more demanding applications generally require piping, which will get up to high pressures and harsh environments.

With this specialized capability, Schedule 80 PVC pipe is usually utilized in situations where water is under moderate to high.PVC is a corrosion-resistant material, and it’s also immune to a variety of chemicals.

Unlike metal pipe, PVC won’t rust, pit, or scale. Inside of the pipe remains smooth, allowing an unobstructed flow of the media inside.

A couple of common uses of schedule 80 PVC include: wastewater management, chemical

processing and use in manufacturing plants.

Differences between schedule 40PVC vs schedule 80 PVC

There are five key differences between 40PVC and schedule 80PVC. These are;

-The wall thickness

-Internal diameter

-Fluid pressure

-The color

-Uses/applications

Let’s look at each of these parameters individually.

1. Wall thickness

This is the main factor that differentiates schedule 80 vs schedule 40 PVC. Schedule 80 is designed to have a thicker wall than schedule 40. This automatically means that it is stronger and can handle more pressure than schedule 40 or any other pipe that is below schedule 80.

It is quite intriguing that schedule 80 can have a smaller diameter with a thicker wall. The main reason for this is the thickness of schedule 80 is inside and not outside.

So, you should not be surprised when the PVC looks thick yet it appears to be small.

2. Water Pressure

The thicker the wall, the more the pressure. This directly implies that schedule 80 PVC can support more pressure than schedule 40 PVC.

Both schedule 40 and 80 PVC are used widely around the world. Each has its benefits in several applications. Schedule 40 pipe has thinner walls, so it’s best for applications involving relatively low water pressure.

Schedule 80 pipe has thicker walls and is in a position to face up to higher PSI (pounds per square inch). This makes it ideal for industrial and chemical applications.

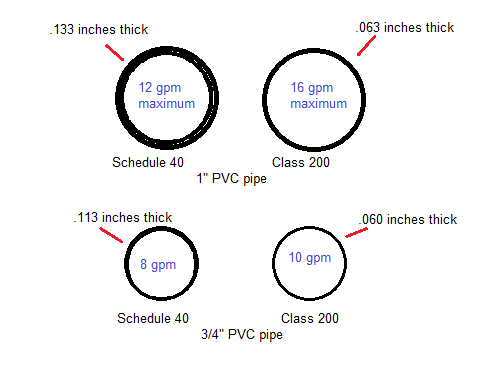

To give you a clearer picture of the dimensions difference, 1” schedule 40 PVC pipe features a .133” minimum wall and 450 PSI, while schedule 80 features a .179” minimum wall and 630 PSI.

Because schedule 40 PVC has thinner walls, it is not recommended in situations where the water pressure is high. The pipe is likely to burst, and this will end up costing you more. Instead, get schedule 80PVC for such applications.

3. Color

Hat color is schedule 80 PVC? What about schedule 40 PVC color? Do you know that the difference between these two can be based on colors?

Colors also can be wont to distinguish between a schedule 40 and schedule 80 PVC. In most cases, schedule 80 PVC pipes are usually gray in color, and schedule 40 is white. However, some manufacturers use different colors for branding and marketing. So it is vital to check the label before buying the PVC.

4. Cost

A schedule 80 pipe is probably going to cost quite a schedule 40. This is often because the previous has thicker walls and is useful in many specific applications.

Still, on the issue of cost, the price of a PVC may vary from one place to another. Some PVC manufacturers sell affordable schedule 40 and schedule 80 PVC.

Always contact the manufacturer directly to confirm the price of PVC.

5. Size and diameter

As mentioned earlier, both schedule 80 and schedule 40 PVC pipe have the precise same outside diameter. This is often possible because schedule 80’s extra wall thickness is on the within of the pipe.

This suggests schedule 80 pipes will have a rather more restricted flow – albeit it’s going to be the same pipe diameter as an equivalent schedule 40 PVC. This means that schedule 40 and 80 pipes do fit together and may be used together if necessary.

The only thing to take care of is that the lower pressure handling schedule 40 parts meet the pressure requirements of your application. Your pipeline is merely as strong as your weakest part or joint, so even one schedule 40 part can be utilized in a better pressure schedule 80 lines can cause severe damage.

6. Weight

Which one is heavier between schedule 80 PVC vs schedule 40 PVC? Generally, the thicker the PVC, the heavier the product. This means that schedule 80 PVC is heavier than the schedule 40.

7. Installation

Installation doesn’t differ between Schedule 40 / 80 piping that has been made from the same n. Abiding by the ASTM standards, outside diameters are going to be equal across schedules of pipe that have equal NPS. This specification allows for pipes of various scheduling to be coupled together using the traditional fittings and joining method for that piping material.

8. Heat insulation

The heavier wall of Schedule 80 PVC pipe offers added insulation, which will be able to maintain the temperature of the water within the pipe. PVC pipe is restricted to the water of not more than 140 degrees Fahrenheit.

This simply means that the thicker walls of the Schedule 80 PVC pipe provide better insulation than the schedule 40 PVC pipes. If you plan to use the pipe for thermal-sensitive applications, then choose schedule 80 PVC.

Which Schedule PVC do I Need?

So what schedule PVC does one need? So, if you are getting to run a high or industrial pipeline, schedule 80 PVC could also be the best choice for your project.

If not, schedule 40 PVC is quite enough for small pressurized and non-pressurized jobs. If you propose to require a home repair or irrigation project, schedule 40 PVC is perhaps the ideal choice.

Even schedule 40 PVC is capable of handling impressive pressure, and it is likely quite adequate for any home or small-scale application.

Schedule 40 PVC is additionally relatively inexpensive, which makes it great for non-plumbing applications sort of a PVC pool chair or science project.

You’ll also save yourself a lot of money sticking with schedule 40, especially if you propose using large-diameter parts. If your job is going to be industrial or chemical in nature, you almost certainly want to use schedule 80.

These are applications that will likely cause higher pressure and stress on the material, so thicker walls are imperative.

Related source links:

Everything You Need to Know about PVC Pipe Sizes

Handbook: Everything you need to know about PETG

PETG vs ABS: What are the Differences?

PETG vs PLA: What are the Differences?

Polycarbonate vs Acrylic: What are the Differences?

Nylon vs Polyester: What are the Differences?

Trivex vs polycarbonate: What are the Differences?

White paper: The Complete Guide To thermoforming

Rocheindustry specializes in high quality rapid prototyping, rapid low-volume manufacturing and high-volume production. The services of rapid prototype we providing are professional Engineering, CNC Machining including CNC Milling and Turning, Sheet Metal Fabrication or Sheet Metal Prototyping, Die casting, metal stamping, Vacuum Casting, 3D printing, SLA, Plastic and Aluminum Extrusion Prototyping, Rapid Tooling, Rapid Injection Moulding, Surface Treatment finish services and other rapid prototyping China services please contact us now.