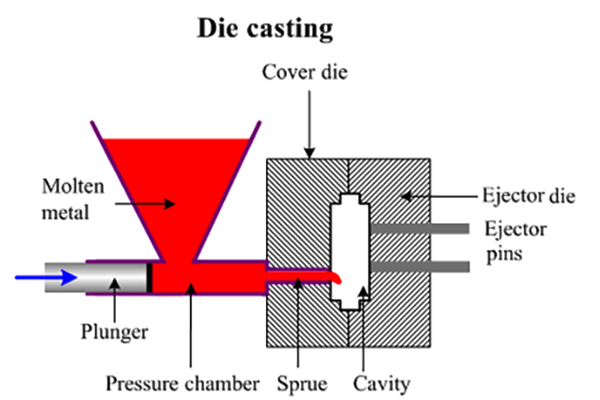

Die casting is a metal casting process that is characterized by forcing molten metal under high pressure into a mould cavity. The mould cavity is created using two hardened tool steel dies which have been machined into shape and work similarly to an injection mould during the process. Most die castings are made from non-ferrous metals, specifically zinc, copper, aluminium, magnesium, lead, pewter, and tin-based alloys. Depending on the type of metal being cast, a hot- or cold-chamber machine is used.

Are you looking for die casting companies in Germany? We have compiled the best 10 die casting companies list for you to pick as below:

Contents

Druckguss Westfalen GmbH & Co KG

Druckguss Westfalen is one of the most advanced and versatile foundries for aluminium die casting. Ever since we started out in 1964, our goal has always been full customer satisfaction. We likewise offer full-service zinc die casting – since 2016 with our sister company Druckguss Westfalen Behringer.

Druckguss Westfalen: Full-service die casting foundry with an extensive and advanced capability portfolio

At our facility in Geseke and at our sister company Druckguss Westfalen Behringer in Velbert, we operate a highly advanced machine park with fully automated die casting cells featuring real-time shot control and serving a vast range of applications. Our services benefit customers in a wide variety of industries – from automotive and electrical engineering to sanitation, mechanical engineering and furniture. Our state-of-the-art machining technology makes easy work of even the most highly intricate, technically sophisticated products. Druckguss Westfalen is additionally your foundry of choice for innovative solutions featuring specific finishing processes.

Specialists in high-quality aluminium die cast component manufacturing

We recently updated our machine park and expanded production and warehousing at our Geseke location to some 14,000 square metres, allowing us to cover an even broader range of aluminium die cast components in medium to large production runs. Sixteen die casting machines with clamping forces of 130 to 1800 metric tons enable Druckguss Westfalen to serve a huge product range. Alongside the latest technology and software (including EDI, Magmasoft and TimeLine), our strengths also include expert consulting in areas such as design for manufacturing (DFM) and technical cleanliness. A modern logistics centre with 3000 pallet spaces ensures reliable on-time delivery.

The zinc die casting professionals

At our sister company Druckguss Westfalen Behringer in Velbert with 2800 square metres of production space, we manufacture high-quality zinc die cast components on 14 hot chamber die casting machines with clamping forces of 20 to 200 metric tons. This facility also fully reflects our lean management approach, with efficient, economic, resource-saving and minimum cost operations.

Druckguss Westfalen: Industry 4.0

We are a one-stop foundry, serving your needs across the entire cycle from development to assembly. Our broad-based, highly motivated and experienced team comprising a total of 200 employees share our passion for excellence in die casting.

Address: Plant Velbert, Industriestraße 54, D-42551 Velbert, Germany

Wolf Group

The family company, founded in 1933 by the grandfather of the current owner under the name “Elektro Wolf” in Regensburg, came to zinc die casting by chance in the post-war period.

Thanks to the addition of aluminum, the Regensburg die-casting plant developed very quickly from 1977 into a dynamically flourishing foundry. In addition to aluminum casting, the Wolf Group still produces around 5 percent zinc die-cast components for the international automotive and electrical industries. The medium-sized company is currently in the third generation and is still 100 percent family-owned.

With a high equity ratio of almost 70% and a healthy growth rate in recent years, the company is primarily geared towards solidity and the long term. Investments in machines and systems as well as the financing of new plants are mainly generated from the cash flow. In this way, the ongoing burdens for the group of companies can be minimized. Above all, the balanced range of products from the automotive and non-automotive sectors, as well as long-term, yet independent customer relationships established the Wolf Group as a reliable and crisis-proof partner.

The economic market changes of the recent past could thus be absorbed without major cuts. The medium-sized company, which is characterized by flat hierarchies, quick decisions and a high degree of flexibility, can therefore also react flexibly and stably to market fluctuations in the future.

With a quality management system as well as the current certifications according to ISO / TS 16949 and ISO 14001, the group of companies meets the global standards of the automotive and electrical industries.

Address: Checkinger Schloss Str. 7, 93051 Regensburg, Germany

AUER GUSS GmbH

Being a mid-sized family-run business with our headquarters in Germany and a subsidiary in the Czech Republic we are part of the global society and comply with applicable laws and regulations.

We are of the opinion that corporate success, compliance with law and order, responsibility for our staff and a responsible treatment of the environment are closely related.

In our company, men and women of various nations and age groups with different skin color, cultural and religious orientation as well as different ethnic and social backgrounds work harmoniously and respectfully together.

Address:Mundfeldweg 11, 92224 Amberg, Germany

Jordan Reflectors GmbH & Co. KG

The traditional company Jordan was founded in Wuppertal in 1924. Today’s Jordan Group has developed from this first production facility. As a long-standing OEM supplier, Jordan sees itself as an innovative full-service partner to the lighting industry.

More than just reflectors ”- that is the main idea.

In addition to its core competence in the field of light control, development and production of standard and custom-made reflectors, Jordan now offers its customers more service and know-how in the field of surface technology, aluminum die-casting and the production of lighting components and assemblies.

Address: Schneiderstr. 76, 40764 Langenfeld, Germany

GP Diecasting

GP Diecasting, which was grounded in 1993, carries out the manufacture of parts from aluminum and zinc alloys with the use of pressure die casting method and provides CNC machining services. Produced parts are exported to Switzerland, United States, England, Netherlands, Northern Ireland, Italy, Malaysia, New Zealand and especially to Germany. They are also utilized in many industries among the local market.

A Quality Management System is practiced in our company, where it has been prepared in accordance with the ISO 9001:2008 accords. The system is continuously updated in order to improve the overall quality. Processes such asSPC, FMEA, PPAP and MSA are implemented meticulously to increase the production quality, to prevent possible faults and for traceability.

In addition to these, Spectral Analysis equipment, metal microscope for material analysis, 3D measurement equipment and hardness measurement equipment are used in our company.

Address: Tuzla Kimya Sanayiciler O.S.B. Melek Aras Bulvarı. No:24 Tuzla, İstanbul / TR

Schweizer Group Global GmbH

The Schweizer Group is a leading provider of aluminium and magnesium components. We are specialists for die-casting and machining applications that meet the highest precision and cleanliness demands.

The core of our philosophy is a project management strategy that sees the customer as a partner. This means close and effective cooperation, from the planning phase through to the series production of components ready for assembly.

We are a valued supplier to large automobile manufacturers, component suppliers and renowned companies in other sectors. Learn more about us – the company that produces components for the future of mobility.

Address: Dieselstrasse 2, 73110 Hattenhofen, Germany

Breuckmann GmbH & Co. KG

The core competence of Breuckmann GmbH & Co. KG is high pressure die casting with raw materials whose the casting exceeds the threshold of 1000°C.

The high pressure die casting process offers ideal conditions for the economic manufacture of precise castings with a high surface quality.

We primarily cast silicon tombac, pure copper and brass for customers in the lock and fitting industry, the electronics and automotive industries in addition to general mechanical engineering.

High pressure die casting at temperatures of over 1000°C is remarkable as the same steel moulds are used again and again, even though these moulds melt at temperatures of approx. 1500°C. Thanks to 50 years of experience in this area, we succeed in delaying the heat-related wear to the mould at such high temperatures, and we also manage to efficiently repair once worn-out moulds. This know-how allows us to combine excellent casting properties with an extremely economical production process, all to the benefit of our customers.

Our great production depth and exceptional innovation expertise differentiate us from our competitors. The company’s commitment to these objectives is seen in the high demand for scientific education and training among our engineers and management and, not least in the substantial investment volume we have made over the past years. Today, Breuckmann GmbH & Co. KG is one of the most modern foundries in the market and a powerful partner with solutions for your tasks.

This makes us strong: All the steps involved in the production of our products are carried out in-house. Direct access to all departments guarantees us lasting quality and flexibility.

Address: Dieselstraße 26-28 | D-42579 Heiligenhaus, Germany

ECS Dieser GmbH Co.KG

Production facilities in Hungary – development and selling agency in Germany.

development and sales (with key account management for certain customers) for the hungarian alu-die-cast foundry Csaba Metal Zrt.

Benefit from our experience and our intercultural competence.

In 2017 we celebrate our 25th anniversary. We are cooperating successfully with most of our Hungarian partners for more than 15 years.

We have a great and well rehearsed network for development, toolmaking and training.

Address: Goldenbühlstraße 15, D-78048 Villingen-Schwenningen

IKAR LMG Gusstechnik GmbH

Casting reflects our expertise, and your product is perfect

Casting is the heart of our work. Thanks to many years experience in light metal casting, we master the different casting techniques perfectly and work with utmost precision.

Whatever the material we use – the final product will be just as you imagined.

We naturally offer different services related to casting – as we are only satisfied when you are!

Address: Wachbergstrasse 13, D-08280 Aue / Alberoda, Germany

Kalmbach GmbH

Kalmbach is one of the most modern and versatile die casting plants in Germany today. At our plant in Velbert, we turn out die-cast aluminum and zinc parts that meet the highest standards. For more than 50 years, we have been working for companies operating in many different industries – both on a national and international level. We engineer and build molds and tools for customers in the hardware, electronics and entertainment, sensor technology and mechanical engineering industries. We machine, finish and assemble castings tailor-made to our customers’ specifications. Our parts are also widely used in the furniture and sanitary ware industries and in the automobile industry.

We currently manufacture precision aluminum and zinc castings custom-made to meet the special requirements of Swiss companies in terms of functionality and aesthetics.

Address: Eintrachtstraße 96, D-42551 Velbert, Germany

Conclusion

How to choose right die casting services company is very important, Without looking further, we’re also die casting services company in China. Rocheindustry aim to give purposeful reviews and information that is bound to save your time. In case of any questions, inquiries, or even comments, reach out to us.

Remember, a happy client is a happy company.

If you’re looking for die casting services with competitive price in China please contact us as below button.

Related source: White Paper: The Complete Guide To Die Casting