Laser drilling is the process that one will use to drill large and small holes on different metals. One can create thru-hole, which is ideal in developing some specific items like cooling air vents. Other holes may be smaller ones to roughen the surface.

Laser drilling will use the laser beam while drilling the metal. You can control the beam with precision so that it restores your desired output. Laser drilling is a concept that has been developing from old technologies.

Also, laser drilling will produce holes of different sizes and shapes on different types of materials.

Contents

How Laser Drilling Works

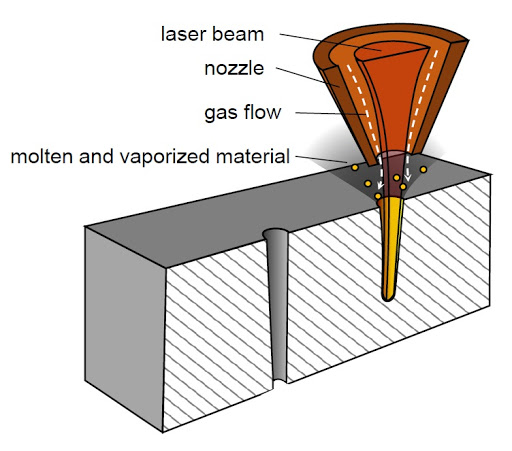

Laser grilling is a unique method of drilling holes by thermal processing techniques. It entirely happens as you use high energy depths. The user will focus on intense beams, which will cause melting and eventually evaporate the material.

Consequently, the steam pressure will trigger particles to come out from the drilling hole. One can use a pulsed laser to get the required results and depths. The process will succeed well due to the following factors.

- Material strength

- Hole diameter

- Processing speed

You have an option to use the three drilling methods. It is always challenging to drill holes that are below 0.25mm. In response to that, you will need laser drilling to precisely drill such holes.

One can drill such holes on any materials. Still, you can also drill comfortably on brittle materials like ceramics, gemstones, and hard metals like steel.

The best method to use when drilling hard materials is trepanning. You will begin by overlapping and initiate the drilling action, which involves circular movements. It is an automatic process that requires proper mask protection.

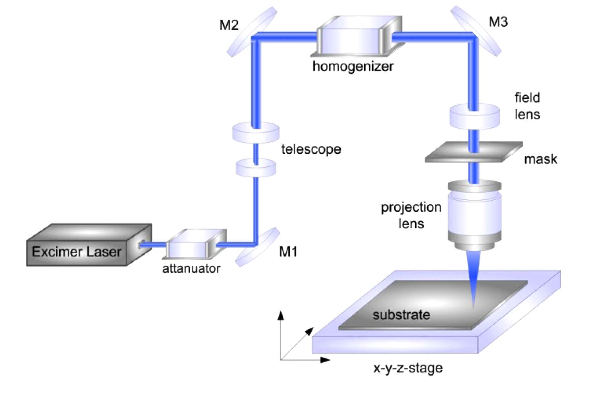

Laser drilling is a process that works well under automation. When you are drilling a hole, the following parameters should be present:

- The wavelength

- Laser beam quality

- Pulse duration

- Intensity

- Pulse repetition rate

You will also need simulation and modeling. By doing so, the process will be more predictable and precise. The cool thing is that laser drilling is proving to be a less costly method as compared to other outdated methods like a mechanical way of drilling the hole.

By doing a micro hole drilling, it is a perfect alternative to punching, CNC, and EDM. Such methods happen to be destructive in the process of drilling a hole. Laser drilling is useful in the manufacturing industry.

The user will enjoy a high accuracy of drilling specific materials like copper, rubber, glass, among others. The method is consistent in precise manufacturing specifications.

You can achieve various sizes of drill holes due to laser power. Also, it will depend on motion control. One will also require to do rapid prototyping to make a particular range of different hole sizes.

Interestingly, the laser drilling method is usually dynamic. One can also use it to alter the hole diameter, edge quality, and hole depth.

The exciting aspect of laser drilling is that the holes have tapers. In other definitions, the hole may not be necessary straight. Also, the hole may have redeposition as you will be making a hole via violent phase changes.

In the process of drilling, the used material will undergo melting. Later, the same elements will undergo cooling before they solidify again. Notably, redeposition happens mostly on long pulses.

You can reduce both redeposition and tapering by choosing shorter pulse durations and wavelengths. It is noteworthy that the laser beam nature can assist the user in drilling hard materials like diamond and other synthetic materials.

Interestingly, you can also create lasers in coated materials. The process is programmable; hence it allows a high- speed drilling.

Types of laser drilling

Trepan laser drilling

Trepan is the process of using multiple layers to drill the hole. You will create the hole by using the percussion method. After that, you will enlarge the hole using the laser. It moves in the circular motion while expanding the hole. The molten materials will automatically begin to fall through the hole.

Percussion Laser Drilling

Here, you will be using one laser to create the required thru-hole. You can produce multiple holes by using this method. Interestingly, you will be using only a single beam. Consequently, one will create more precise and deeper holes.

Helical Laser Drilling

Helical laser drilling is almost similar to Trepan drilling. The notable difference is that you may not need an initial pilot hole. The laser will operate by moving in a circular motion from the outset. The excess materials will begin to shoot upwards instead of going in the downwards motion.

So, among the three mentioned laser processes, which is the best? Well, it will largely depend on the outcome of a particular one, out of what you want. There is a process that is fast to use.

On the other hand, another one may be slow but comes with precision holes. It will be reasonable to consult a specialist if unsure.

Materials Used for Laser Drilling

There are various materials that one can use to drill. They are as follows:

Plastics

You can use laser drilling on plastics. It can be on printed wire boards (PWB) or Printed circuit boards (PCB). One can also drill holes in multilayered boards featuring different materials such as an insulator and copper.

Another perfect example is to drill sound suppression holes; you can do it on polymeric engine liners meant for aircraft. Some other materials are PET, PVC, and polymer composites.

Metals

Most of the metals are suitable for laser drilling. The most common ones are:

Silicon

Silicon is usually a delicate and thin material. You can use it to make printed circuits in automotive industries. While laser drilling silicon, it will not result in edge melting or creating micro cracks. It will leave the material in the correct form

You also find printed circuit boards in phones, computers, and televisions. One can also use high-speed laser drilling in silicon materials to develop solar cells of high efficiency. The process will take a few seconds to be ready.

Diamond

You can apply laser drilling to improve the quality of the diamond. It is a reliable method for enhancing the clarity aspect. The beam will make small holes, thinner for the human eye to detect.

Also, the laser beam will melt any impurities in the diamond material to make it pure. The purer the diamond, the higher the value. Also, you can use a laser drilling process when filling in any cracks on the diamond. As a result, the diamond will remain new.

Steel and nickel

It is possible to create precision holes in some well-known metals like steel and nickel. As a result, one can fabricate many items in the process. When you create micro holes, the material can be useful in making medical supplies and pharmaceutical industries.

Some of the accessible equipment that is a result of laser drilling are syringes, ampoules, and more. Laser drilling is also a preventative measure. You can use it to check the defect on the medical equipment like syringes. One can determine if it has a possible leak.

Rock

Most of the companies in the gas and oil industries use laser drilling to cut through the rocks. It appears to be a new concept that is causing waves in the market. It is a useful alternative method for other drilling approaches.

One great advantage is that it reduces costs on drilling, especially the geothermal walls. As it gains popularity, laser drilling will become a standard in the oil and drilling industries.

Ceramic

You can also use laser drilling to drill some brittle material. The most common element in this category is a ceramic material. It will give it an excellent finish.

Advantages of Laser Drilling

- It is a non-contact technique. The type of drilling medium involves light. In other definitions, you will not need physical contact between the workpiece and moving parts. It will not wear the drilling part as well as contaminating the workpiece.

- One can create high aspect ratios. You can easily produce small holes with an aspect ratio of 30:1.

- Laser drilling is a method that works perfectly on different materials without breaking them. They may range from metals to rocks, wood, and rubber.

- The process of laser drilling can achieve multiple tasks. You can, therefore, program it to adapt to particular tasks.

- Laser drilling is a quick process that will increase your production.

Disadvantages of laser drilling

- The process will demand high capital to start it

- Some processes may produce excess heat leading to cracks to some material.

Conclusion

Laser drilling is proving to be an effective method as compared to other conventional means. Firstly, it simplifies work and allows you to have mass production of the same items within a short period.

You can overlook its downsides and make it a priority by adopting its principles. By doing so, you become more relevant in the industry. You can make the decision now and fail to regret it later.

Related source links:

Handbook: The complete Guide to Laser Etching

Handbook: The Complete Guide to Laser Welding

Handbook: The Complete Guide To Laser Cutting

Handbook: The Ultimate Guide to Selective Laser Sintering

Rocheindustry specializes in high quality rapid prototyping, rapid low-volume manufacturing and high-volume production. The services of rapid prototype we providing are professional Engineering, CNC Machining including CNC Milling and Turning, Sheet Metal Fabrication or Sheet Metal Prototyping, Die casting, metal stamping, Vacuum Casting, 3D printing, SLA, Plastic and Aluminum Extrusion Prototyping, Rapid Tooling, Rapid Injection Moulding, Surface Treatment finish services and other rapid prototyping China services please contact us now.