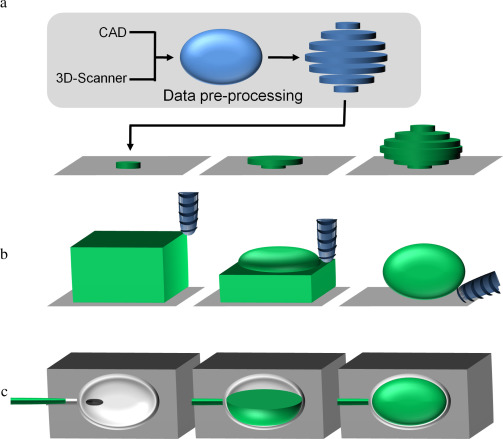

Rapid prototyping image couretsy sciencedirect

Contents

Rapid Prototyping Overview?

Any production process starts with prototyping. This is something that has been there for ages. Usually, product designers or product engineers would create models of the product using very basic tools. Traditional prototyping was cumbersome and costly. It is what led to rapid prototyping.

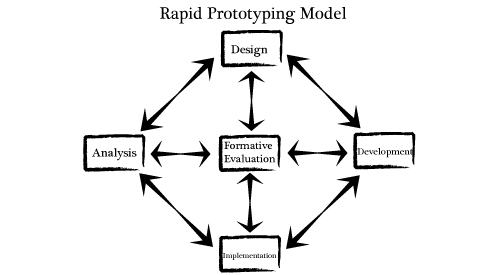

Rapid prototyping (RP) assists organizations with transforming ideas into sensible proofs of concepts. It progresses these ideas to high-constancy models that look like the final products.

It also provides guidelines through a progression of approval stages toward large scale production. In the rapid prototyping, engineers and product designers create prototypes using CAD

In this comprehensive guide, I am going to let you learn everything about rapid prototyping for product development I will strive as much as possible to answer all the questions this product design prototype method.

What is Rapid Prototyping?

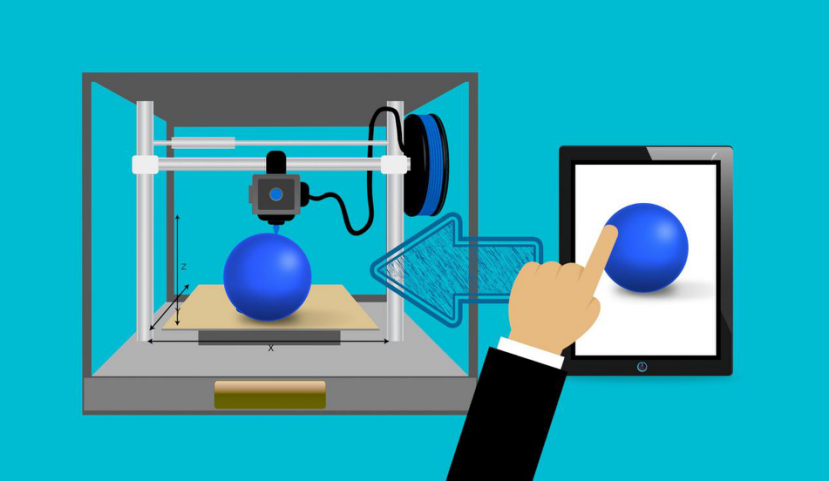

Rapid prototyping refers to a group of techniques that you can use to quickly fabricate a model of a product using a 3D computer-aided design(CAD) data. The creation and the assembly of the model is usually completed using additive manufacturing which is commonly referred to as 3D printing.

Additive manufacturing is used for creating a perfect match with the finished product. This flawless match is usually referred to as a high fidelity prototype. On the other hand, a low fidelity prototype has clear demarcations with the finished product.

Rapid prototyping is an ideal method since it gives product designers the freedom to produce parts that have accurate mechanical properties. It also does not require any form of tooling.

So, what is the difference between rapid prototyping and 3D printing?

3D printing which is also referred to as additive manufacturing since successive layers of the materials is added. On the other hand, prototyping focuses on creating models of the end product. using a computer aided design (CAD)

3D printing technology has been there for decades but was limited to large corporations due to the cost and constraints involved. Those who didn’t afford it resorted to hiring the 3D services from third-party providers who were always slower and more expensive.

How Rapid Prototyping Works

Although rapid prototyping encompasses different types of the manufacturing process, all of them utilize the principles of additive manufacturing or 3D printing technology. Other technologies that are used for rapid manufacturing include high-speed machining, moulding, casting and extruding.

There are two other conventional processes that are used in rapid prototyping. These are subtractive and compressive processes. In the subtractive process, a block of material is carved off and used for producing the desired shape. On the other hand, a compressive process is where a liquid or semi-solid material is forced to adopt the desired shape before it is finally solidified.

What are the Different Types of Rapid Prototyping Techniques?

Here are the main types techniques that you can use to achieve rapid prototyping;

1. Stereolithography (SLA)

Stereolithography was the first ever commercial 3D printing method. It entails solidifying a bath of photosensitive liquid using the UV light. A computer software is used for controlling the process. The liquid will eventually form a single solid layer.

The solidified layers are formed from the two-dimension cross-sections of the 3D CAD. This fast prototyping technique is an ideal choice for making patterns that are to be used in vacuum casting. It is also cheap and the finished prototypes tend to have a smooth surface finish.

2. Selective Laser Sintering (SLS)

This fast prototyping technique entails using a powder bed fusion. The parts of the desired final product are formed on a build plate sequentially. The function of the laser is to sinter the powder media hence the name. In this technique, you won’t need additional structures to support the powder media.

The good thing about SLS is it can be used on both plastic and metal prototypes. It is also good for making complex geometries which other methods may not achieve. The only issue is the surface finish of the prototype is quite rough.

3. Selective Laser Melting(SLM)

This is another fast prototyping technique that uses powder bed fusion. It requires high precision controlled conditions to create the best prototypes. Fine metal powder of uniform shape and size are welded onto a build plate. A powerful laser is then used for sealing the chamber.

SLM is the best method for making complex parts that are strong and durable. However, it is quite an expensive technique and should be executed by an experienced engineer. Some of the fields that utilize this technique include automotive, medical and aerospace.

4. Laminated Object Manufacturing

This technique entails laying down a series of laminates on a build platform. These laminates can be plastics, paper or metal foil. Each layer of laminate is traced using a computer-controlled laser although you can use alternative cutting devices. The build platform is used to minimize the thickness of each layer.

5. Fused Deposition Modeling(FDM)

If you want to deploy rapid prototyping for home or small business, this is the ideal technique that you should use. A desktop machine is usually used to control the operation of this method.

The method uses a plastic filament that is melted inside a printing nozzle. A hot liquid resin is then laid layer after layer. An stl program is used for cutting the layers. The method is cheap and has a wide range of applications.

6. Binder jetting

This is among the newest 3D printing method for fast prototyping. It is perfectly curated for mass production. The method entails covering a metal powder on a horizontal print platform. Numerous nozzles are then sprayed in the form of fine droplets to bind the layers.

The layer is then compacted then coated again with the powder. It will then be sprayed in preparation for the next layer. This technique allows several layers to be printed at a time.

7. Digital Light Processing

This technique is similar to the SLA only that it is better at curing the resin. It also needs to be supported by some support structures. It is faster, cheaper and produces smooth finishes.

Video of rapid prototyping principle

Advantages of Rapid Prototyping Model- Benefits

Why rapid prototyping? You may find yourself asking this question. There are many benefits that you stand to gain if you embrace the rapid prototyping for product development. Some of these benefits include:

1. Fast product development

Time is of great essence in any production process. You would like to finish up with the product within a short time. Rapid prototyping manufacturing can help you to achieve this goal.

Although the CNC method can be used on simple equipment within a short time, the case will be different when dealing with complex parts. It will take you long to come up with a prototype. 3D printing will reduce the lead time for prototyping and this will affect the entire production process.

2. Affordable prototyping method

3D printing is always considered as an affordable way of getting your prototype done. It is way cheaper than the CNC machining. If you choose to use the CNC machining, then you should prepare to spend some huge amount of money. You will be forced to buy several equipment and accessories. Such equipment includes the monitoring machine and programmings tools.

In a rapid prototyping technique, you only need to send the file to a 3D printer and it will interpret the 3D data model. The minimal financial implications of the rapid prototyping technique will have a direct impact on the cost of production.

3. Allows full tests of different designs

During a design stage of product development, engineers and designers strive as much as possible to avoid flaws which can lead to expensive revisions. Rapid prototyping is perfectly curated for conducting thorough tests that will eliminate any design issues.

Through this elaborate 3D printing, engineers can test sophisticated designs which will be costly if tested in CNC machining. You will not need complex and expensive tools to test different designs.

Given that the prototyping technique uses the layer-by-layer method, those inaccessible parts of the products will still be produced. They include parts with thin walls and very sharp corners.

Through testing of the prototypes not only minimizes the flaws but also it saves time and energy.

4. Seamless communication

Rapid prototyping process provides a clear platform for different parties to communicate easily and efficiently. Designers and engineers can easily share ideas with their colleagues, and clients. The communication is made simple thanks since the prototypes are visualized on screen.

Proper communication during a production process plays a big role in ensuring that the end product meets the desired standards.

5. Consolidation of parts

Rapid provides adequate room to explore each part that will be used on the final product. You will be in a perfect position to visualize whether the parts will fit into the product perfectly.

Parts consolidation will also give you an opportunity to explore alternative parts that can be used in place of the originally intended parts.

6. Risk reduction

One of the most pronounced benefits of fast prototyping is risk mitigation. By seeing a design of the product beforehand, you will be in a position to avert the risks that can occur at later stages of the production process. Some of the risks can even occur when the product is already in the market.

Since rapid prototyping is not very expensive, the cost of risk mitigation will be minimal.

Applications of Rapid Prototyping and Examples

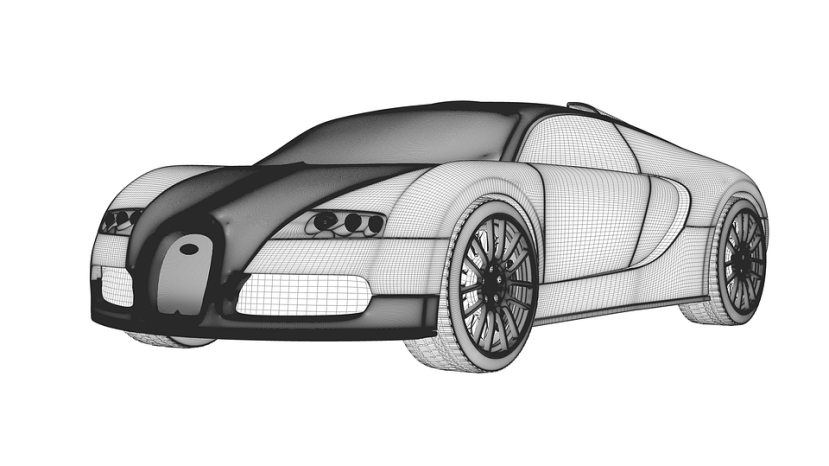

Prototype of automotive source: Pixabay

Prototype of automotive source: Pixabay

There are numerous rapid prototyping applications for different industries. The applications can perfectly fit into different stages of production, whether it is at the conceptual stage or at the finishing stage.

At the conceptual stage, the fast prototyping method helps designers and engineers to validate their ideas and test the viability of the product. The prototype model at this stage of production can be used by all the parties that are involved. This includes the clients.

The next stage, the prototype is used for visualizing the product’s functionality. The design and other aspects that were proposed at the conceptual stage are verified. Rapid prototyping is also used to create a model for the finished product. Features such as finish polishing and electroplating are highlighted.

Examples of rapid prototyping applications

Here are some of the most popular applications of rapid prototyping in the modern world:

1. Product design

-CAD model validation and

-Proof of concept

-Visualization of products

2. In manufacturing and tooling process

-Direct soft tooling

-Direct hard tooling

-Direct soft tooling

-Indirect hard tooling

3. Automotive industry

-Gearbox design and verification

-Designing engine block

-Designing a driver control system

4. Automotive industry

-Designing an aeroplane electrical generator

-Aeroplane engine components

-Verification of aeroplane casting

5. Biomedical industry

-Planning for reconstructive surgery procedures

-Brain tumour surgery

-Prototypes for tissue engineering

-Designing parts for an organ transplant

Time To Embrace Rapid Prototyping

From the benefits of rapid prototype development, it is time to take that critical step. Embrace this method of developing your product prototypes. You will be amazed by how much time you will save with this technique. If you are running a small scale business, the method will motivate you to embrace large scale production.

The versatility of rapid prototyping applications means that you will find the method useful in your production. Whether it is a moulding, casing, machining among others. We cannot underscore the cost-effectiveness of rapid prototyping for product development.

To gain the full benefits of this prototyping process, you should use the right rapid prototyping tools. With the right tools, you should expect to experience magical results.

Quality and Affordable Rapid Prototyping Services

At Roche Industry, we are proud of providing outstanding rapid prototyping services to our clients. We have adequate experience that makes us produce quick prototyping service. As an established company, we are well-equipped with high-end rapid prototyping tools, including the latest 3D CAD software.

We also have a team of engineers and designers who will get the job done. All you need to do is contact us and we will deliver your 3D rapid prototyping project.

References:

Uses of rapid prototyping

https://www.worldscientific.com/doi/abs/10.1142/9789812388834_0007

Rocheindustry specializes in high quality rapid prototyping, rapid low-volume manufacturing and high-volume production. The services of rapid prototype we providing are professional Engineering, CNC Machining including CNC Milling and Turning, Sheet Metal Fabrication or Sheet Metal Prototyping, Die casting, metal stamping, Vacuum Casting, 3D printing, SLA, Plastic and Aluminum Extrusion Prototyping, Rapid Tooling, Rapid Injection Moulding, Surface Treatment finish services and other rapid prototyping China services please contact us now.